New devices improve thermal efficiency, reducing power consumption and data center costs

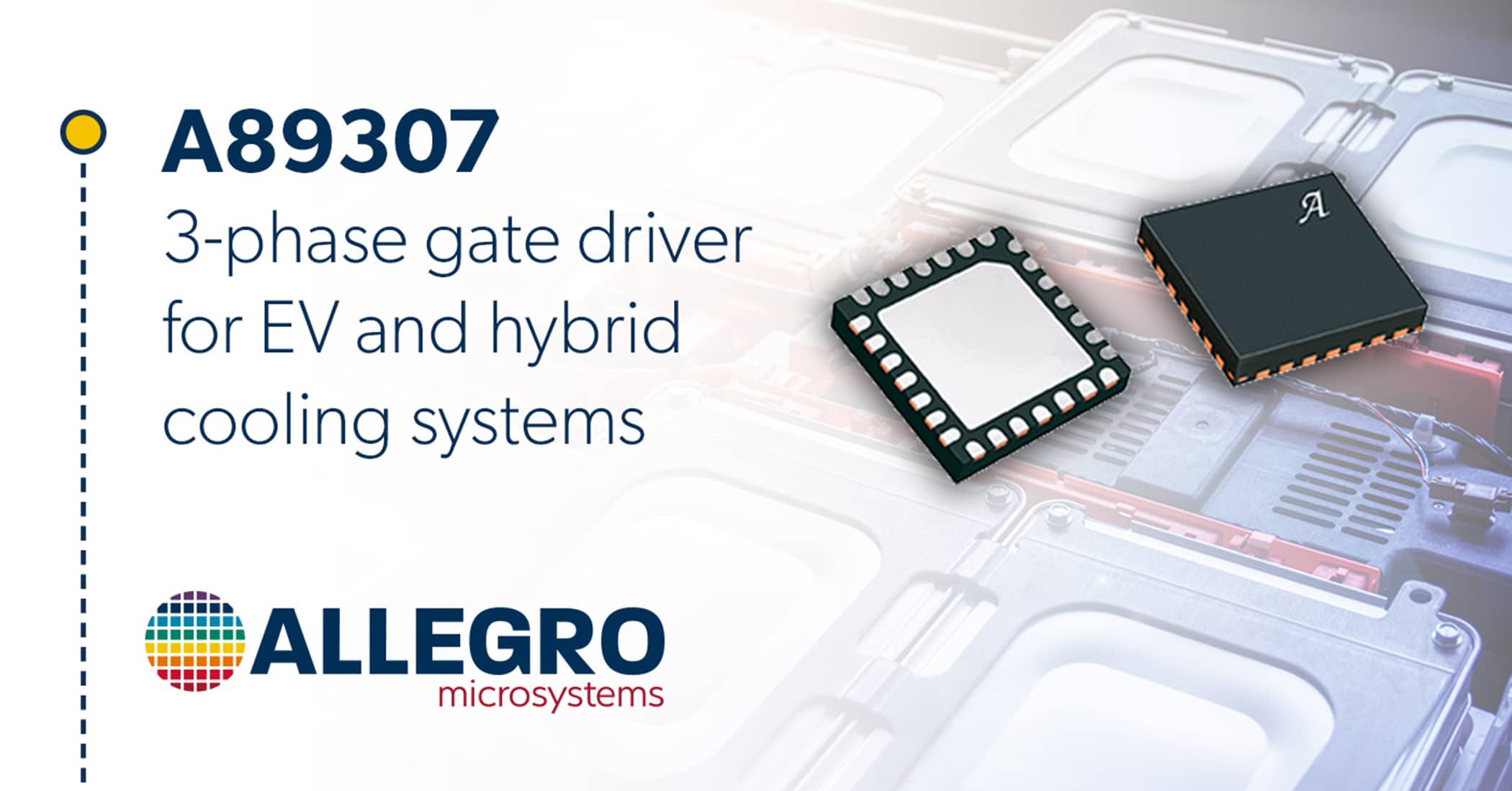

Allegro MicroSystems announces that it has expanded its portfolio of sensorless 89332-phase BLDC gate controllers. Its latest offerings, A89332 and A1-89332, are designed to meet the changing needs of cooling systems in today's data centers and offer flexible options for designers. Available with innovative built-in energy loss brake (A89332) and AC loss (A1-XNUMX) features, these controllers enable compact, high airflow fan designs to improve thermal efficiency, reducing energy consumption and costs from the data center.

When server fans malfunction or break, backflow causes them to spin in reverse. The other fans have to work harder to compensate for the resulting airflow, which increases power consumption. The traditional solution to prevent reverse rotation is to add external circuitry and components to act as a power loss brake, components that don't fit into 1U fans. This approach requires software coding, increases the size of the Bill of Materials (BoM), and increases time to market.

Addressing these pain points, the A89332's built-in Power Loss Brake (PLB) function applies a brake to malfunctioning fans and prevents them from spinning, with four times better braking performance than conventional implementations. discreet. This eliminates unnecessary power consumption and increases thermal efficiency, ultimately lowering data center costs. When combined with the AC loss logic of the A89332-1, Allegro can now offer the high-end server market with gate drivers that are offered in a 4mm x 4mm QFN package that is 36% smaller. than comparable options, perfect for donut PCBs.

Allegro offers the industry's only code-free solutions for server cooling fans; The company's innovative built-in algorithms and graphical user interface (GUI) eliminate the need for an additional Hall-effect position sensor and motor control unit (MCU), and no additional software development is required. This helps system designers reduce R&D overhead, simplify engine configuration, and improve time to market. The reduced need for external components further helps optimize system cost and improve reliability, and built-in functionality gives customers greater flexibility when faced with stringent design requirements.

Both door controllers build on Allegro's history and experience in developing unique motor control devices for the automotive and industrial markets. With more than three billion sold in the last decade, the company's safe and reliable motor controllers have helped manufacturers innovate safer, more robust motor controller solutions with greater reliability. They can be found in automotive, industrial and consumer applications in products ranging from electric vehicles to cordless power tools and vacuum cleaners.

“The need to build data centers that run more sustainably and consume less energy is accelerating,” says Andy Wang, director of product line for Motors at Allegro. “It's not just about building low-maintenance 'lights out' facilities; Server and component designers are looking for new and innovative ways to reduce heat and power consumption, and fans play an important role. We have been focused on the data center market for some time, and with the addition of the A89332 and A89332-1, we are giving them enhanced control over their cooling systems for maximum efficiency.”

Both devices are available in a 4-contact 4mm × 26mm QFN package with exposed thermal chip (EX suffix). These packages are lead (Pb) free, with a 100% matte tin lead frame coating. For product pricing and samples, contact an Allegro sales office or authorized distributor. For data sheets and more information on Allegro's door controllers, including the new A89332 and A89332-1, visit the Allegro website.