New innovations help customers increase efficiencies and reduce costs, while helping them achieve higher safety standards

Allegro MicroSystems today announced that it has supplied its three billionth motor controller IC, reinforcing the strength of its motion control business. The company's reliable motor controllers have helped customers around the world innovate safer, more robust motor drive solutions with greater reliability. They can be found in automotive, industrial, and consumer applications in products ranging from electric vehicles to data center servers and cordless power tools.

The increasing pace of electrification and advanced driver assistance systems in the automotive industry is driving demand for high-performance motor controllers that help reduce noise, increase efficiency and integrate functionality that enables designers to reduce the number of components and decrease total system costs. Automakers need products that can withstand the harsh conditions found inside modern vehicles while meeting high safety standards, helping improve battery life between charge cycles and reduce weight. Allegro motor controllers can be found in critical applications such as cooling fans, starter generators, transmissions, and advanced 48-volt battery systems.

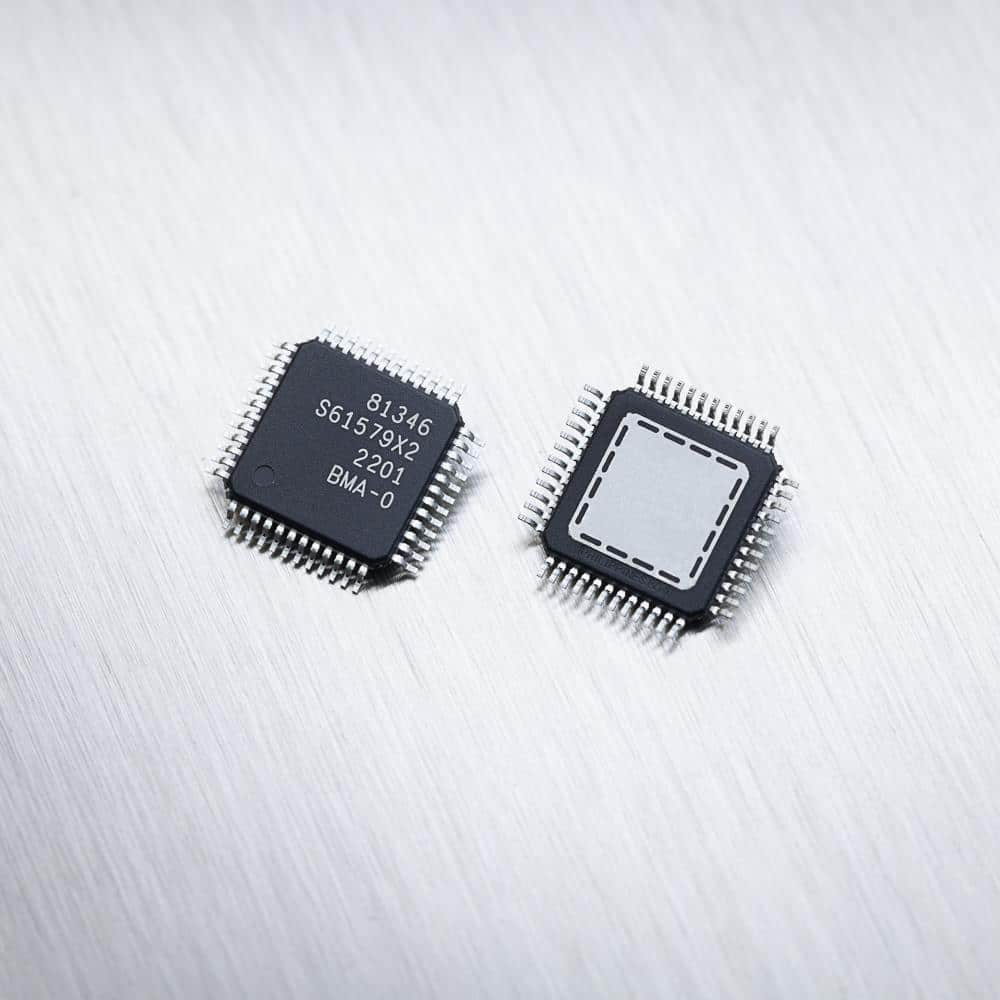

The past decade has seen a push towards battery runtime requirements in the industrial sector as well, with a focus on increasing runtime between charges in applications such as order picking robots found in warehouses. compliance. The shift is also happening in consumer products, such as cordless power tools, which are rapidly replacing older corded models. Allegro motor controllers meet or exceed customer needs in both consumer and industrial applications by integrating features, reducing package sizes, and improving ease-of-use to help manufacturers reduce costs, simplify bills of materials (BOMs) and allow for smaller form factors.

The company attributes much of its recent momentum to a development process that emphasizes partnerships and co-development with customers, with some relationships spanning more than two decades. By working closely with customers, the Allegro team is often able to develop single-chip solutions for different use cases, allowing many customers to move to single-platform approaches for multiple product lines. This can provide significant savings for companies that sell products with different voltage requirements, such as power and garden tools.

“We add value by helping our customers improve time to market and shorten development cycles; we win when they win, and that motivates us to continue to develop new motor controller products,” says Steve Lutz, Director of Allegro's Motor Business Line (Automotive). "We continue to innovate with new products that reduce power consumption, improve battery life, and minimize our carbon footprint."

The Allegro team has increased investments in motor controller R&D in recent years, leading to further advancements in its deep embedded motion control IP portfolio. Introduced in 2019, the company's QuietMotionTM motor controllers include the first field-oriented (FOC) brushless direct current (BLDC) electric motor controllers on the market that require no customer code. These devices are designed to provide reliable and efficient low-noise performance while reducing design cycle times through simple parameter adjustments, which users can access through intuitive graphical user interfaces.

“Many of our customers – especially those in growing emerging markets – lack dedicated motor controller software development resources, often relying on freelance programmers and contractors,” says Andy Wang, Product Line Manager. of Allegro (industrial) engines. "We're helping those customers significantly reduce development overhead by embedding code directly into the CI, which helps them get to market faster."

Allegro's products are designed to create positive environmental and social impacts, helping customers address global challenges related to carbon emissions, energy efficiency, and clean and renewable energy. The company takes a sustainability approach to semiconductor design and manufacturing, integrating sustainable practices throughout its supply chain and operations. In addition to hybrid and electric vehicles, Allegro motor controllers can be found in applications aimed at reducing environmental impact, such as solar arrays, data center fans, high-efficiency HVAC systems, and more.

To help customers better address their changing needs, Allegro plans to launch several new motor controllers over the next year. These upcoming devices will feature new and expanded capabilities that will help further improve battery life and enable a single platform approach, all while reducing overall system costs.