Dedicated to industrial equipment that requires an Ethernet and CAN supervisor

Toshiba Electronics Europe GmbH ("Toshiba") has announced the availability of twenty new M4N ARM® Cortex®-M4 suite microcontroller devices manufactured on a 40nm process. These devices further extend and enhance the top class of the TXZ+TM family and also include an ARM Cortex-M4 core with floating point unit (FPU), running at speeds of up to 200MHz, onboard 2MB code flash memory and 32kB flash data memory with a life of 100k write cycles. These new microcontrollers also offer a number of interface and communication options such as Ethernet, CAN and USB twenty FS OTG with integrated PHY.

This type of microcontrollers of the M4N set are ideal for automation applications of office equipment, buildings and factories, thus for use in industrial networks and information management devices. In the consumer space, these devices are convenient for IoT-based home appliances, home security, and smart meters, among many others.

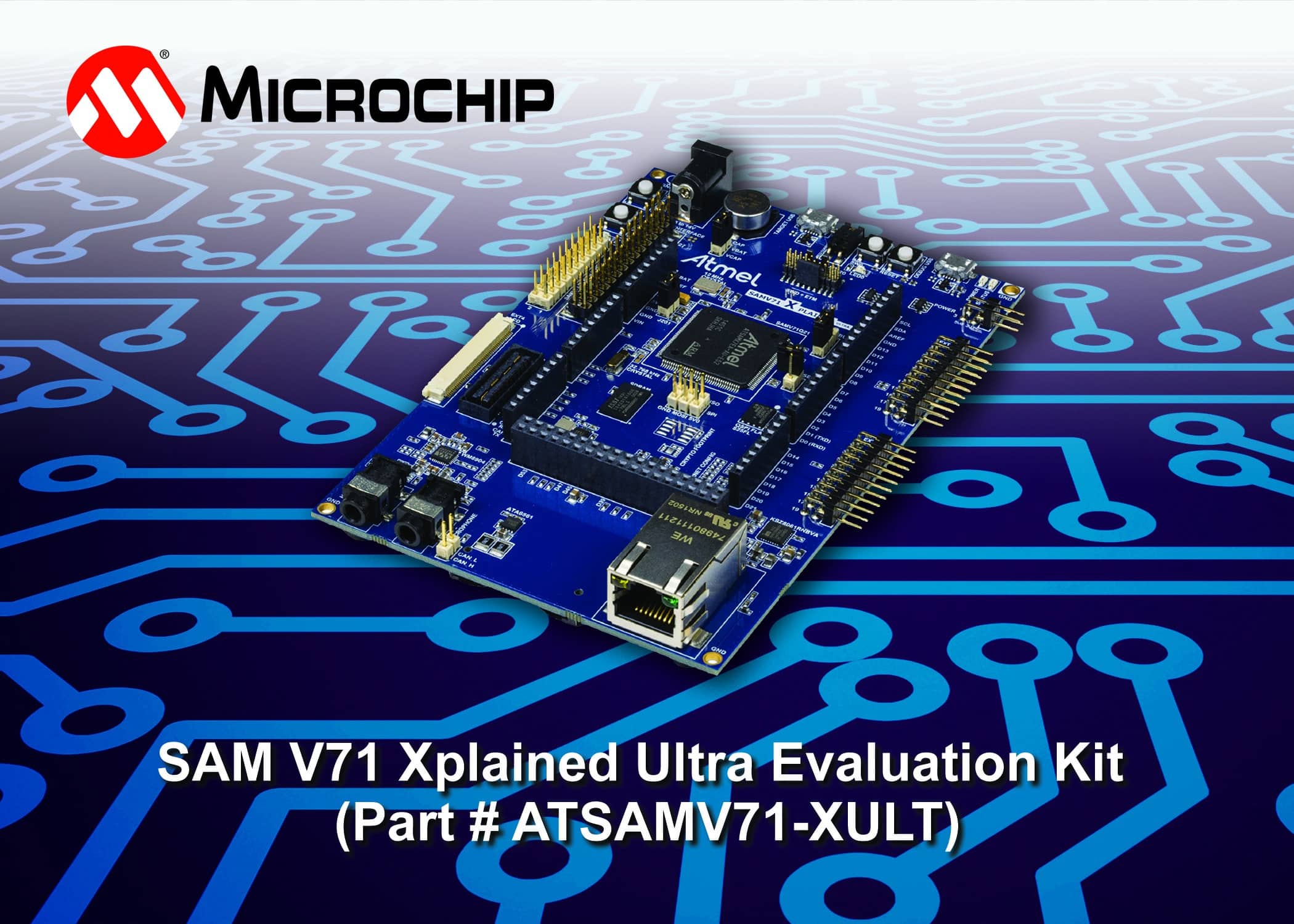

The new products in the M4N suite have built-in enhanced communication functions including a serial memory interface that also supports Quad/Octal SPI, an audio interface (I2S) and an external bus interface, apart from UART, FUART, TSPI and also I2C supported by a built-in three-unit DMAC. In addition to this, the devices can allocate independent DMA and RAM for each peripheral circuit, and use a bus matrix circuit configuration that allows the bus teacher to transfer data efficiently. As a result, the devices of the M4N set allow parallel and independent processing of an Ethernet supervisor, a CAN and a USB supervisor.

The newly announced devices support a variety of sensing applications with a high-speed, high-precision XNUMX-bit analog-to-digital converter (ADC) that allows individual sample and hold times to be set for each of the ADC's twenty-four input channels. The new devices also include a dual-channel digital-to-analog converter (DAC) and a host of motor control functions.

Self-diagnostic functions built into the devices for ROM, RAM, ADC, and clock assist service customers in achieving IEC60730 Class B functional safety certification.

Complete documentation, sample software (with actual usage examples), and supervisor software that controls the interface of each peripheral are available for download from Toshiba's site. To further facilitate the design process, test boards and development environments are provided in cooperation with partners in the global ARM ecosystem.

The new devices are available in a selection of fine pitch LQFP and VFBGA packages. Mass production starts in October.