SIMATIC and Simulink controllers are integrated to make implementation and control algorithms fast and affordable

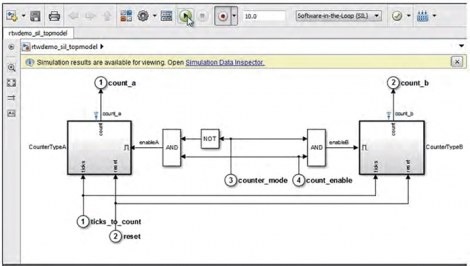

MathWorks has announced the expansion of its relationship with Siemens Automation Systems with the purpose of helping its clients can benefit from model-based design in the development and implementation of complex control algorithms. Control engineers can now generate code in Simulink and implement it on SIMATIC S7 Modular PLC controllers and SIMATIC WinAC RTX software controllers from Siemens. As a result, advanced control strategies can be designed and simulated to test concepts before further validation is performed on the PLC hardware. To support this integration, Siemens Automation Systems has also joined the MathWorks Connections Program.

Model-based design allows verification of critical and complex control functions through simulation. Conceptual errors are detected early and can be corrected before the control algorithms are implemented in the physical hardware. Thus, the development period is shortened and the start of production is made more efficient, which reduces the costs of the entire project.

Simulink PLC Coder from MathWorks generates Structured Control Language (SCL) code according to the IEC61131-3 standard and can output it to the STEP 7 V5.5 engineering system for SIMATIC S7-300 and S7-400, as well as STEP 7, integrated into the TIA Portal engineering framework for the latest generation of the SIMATIC S7-1200 and S7-1500 controllers.

For more computationally intensive algorithms, MathWorks Embedded Coder generates ANSI/ISO C code that can be implemented in WinAC RTX using Siemens WinAC Target, a free Siemens plug-in for Simulink. WinAC Target automatically generates all the files and program modules required to run the Simulink algorithm in WinAC RTX, enabling process engineers without in-depth knowledge of the Simulink language to receive and deploy Simulink models to the Siemens drivers.

“A growing number of control engineers in the machinery and automation industries are using simulation and automatic code generation to complement industrial controller programming, helping them move from idea to implementation more quickly. , as well as increasing its leadership in innovation,” says Philipp Wallner, Sector Manager for Machinery and Industrial Automation at MathWorks.