Harwin announces that their Kona series of high power connectors now have back covers. Made from aerospace grade 6061 aluminum alloy, these back covers prevent the leakage of Electromagnetic Interference (EMI) from the wiring/connecting product to the surrounding environment.

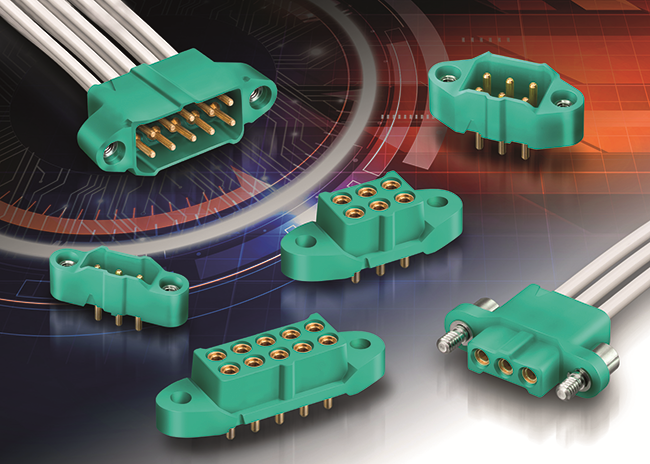

Harwin Kona connectors with 8,5mm pitch are compact and slim but also capable of carrying high currents (up to 60A per contact) and are supplied in 2, 3 and 4 contact versions. Since their introduction in late 2020, these high-reliability components have been found in numerous mission-critical applications, including new space applications, electric vehicles, UAVs, and robotics.

The two-piece construction of Kona's back covers allows engineers to easily retrofit their existing cabling products with 360˚ EMC shielding. This capability is especially beneficial if an EMI problem arises during the development process or when equipment already installed in the field undergoes an upgrade that reveals new EMI problems. In addition, there is the possibility of mounting the connector on the board or panel to offer a complete shielding.

"In those situations where the power connectors are close to a DC/DC converter, such as in the charging infrastructure of an electric vehicle, the high currents carried can cause distortion waves that affect the converter," he explains. Ryan Smart, Vice President of Product at Harwin. “The easy mount option we have added adds a very valuable dimension to our Kona series for solving problems like this.”

Kona rear covers feature robust construction to ensure long-term reliability in harsh environments. Its installation does not require special tools, which speeds up and facilitates assembly. Additional strain relief on the cable braid helps eliminate the risk of damage to the assembly once installed and operational. The rear covers are also supplied nickel plated for added protection against corrosion and oxidation in the field.