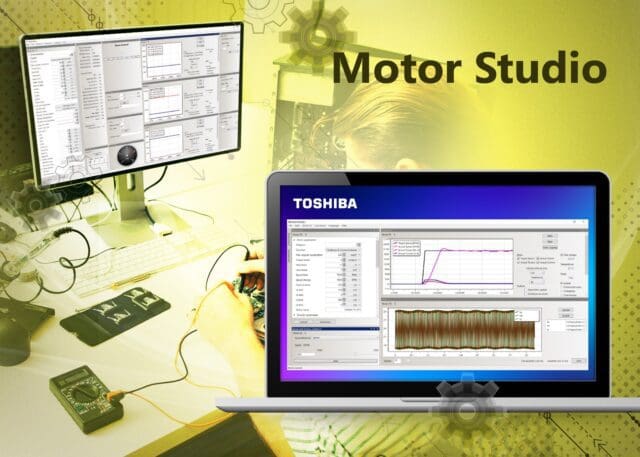

MCU MCU Motor Studio firmware and GUI, plus low-cost hardware developed with MikroElektronika (MIKROE), reduce development time by leveraging TXZ+™4A MCUs

Toshiba Electronics Europe GmbH ("Toshiba") has introduced MCU Motor Studio, which brings together low-cost PC-based design tools, microcontroller firmware and evaluation hardware to accelerate time to market for hosted motor control applications. Toshiba TXZ+™4A microcontrollers (MCUs).

The new MCU Motor Studio firmware set supports all common energy efficient motor control strategies, including sine wave commutation and Field Oriented Control (FOC) (vector), sensorless or with precise position sensing. You can choose between single-tap and triple-tap current sensing, and it supports PWM frequencies up to 156 kHz. The firmware supports all common motor types, including Brushless Direct Current (BLDC) and Permanent Magnet Synchronous Motors (PMSM). It also supports Switched Reluctance Motors (SRM) and Asynchronous AC motors.

Users can control up to three independent motor channels with a single MCU, depending on the selected variant. The TXZ+™4A series, based on the Arm® Cortex®-M4 core, comprises the M4K and M4M groups, which allow motor control even with low-cost 64-pin MCUs. On-chip specific motor control functions include a hardware vector motor, an advanced high-resolution encoder for servo motors, and a self-diagnostic system that facilitates compliance with functional safety standards such as IEC 60730 class B.

The firmware suite offers selectable features that allow users to quickly configure controls such as zero current point detection, motor home position detection, and the most common stop controls, including fast braking. Other features include magnetic field stall recovery, load-dependent speed reduction, advanced rotor control with sensorless precise positioning, and linear motion control with sensor-based precise positioning.

The PC-based motor control tool helps users quickly configure the Proportional-Integral (PI) controller, enter the chosen motor and inverter board parameters, and start evaluating the solution. The tool graphically displays measurements of target and actual speed, torque, current, temperature, and DC link voltage, and monitors error status, all in real time. Users can change motor, system and control parameters dynamically and schedule tests to run automatically.

To help users get their projects up and running, Toshiba has collaborated with MikroElektronika to create the MIKROE Clicker 4 evaluation board for TMPM4K and a 6V-48V inverter shield. Together, they provide a low-cost development hardware platform suitable for driving an engine channel. The evaluation board contains an M4K MCU and can be powered from a USB port, battery, or from the inverter board, which has its own switched-mode converter. The inverter allows current measurement of one or three derivations (shunt) and has a flexible interface for position detection that the user prefers.