With the increasing importance of IoT and communication libraries in Industry 4.0, simple controllers are no longer sufficient as a tool for firmware developers. Due to increasing demands on performance, complexity and flexibility, it is mandatory to use a middleware to fulfill future IT and real-time communication tasks.

Generic Open Abstraction Layer -> GOAL – an industrial communication middleware

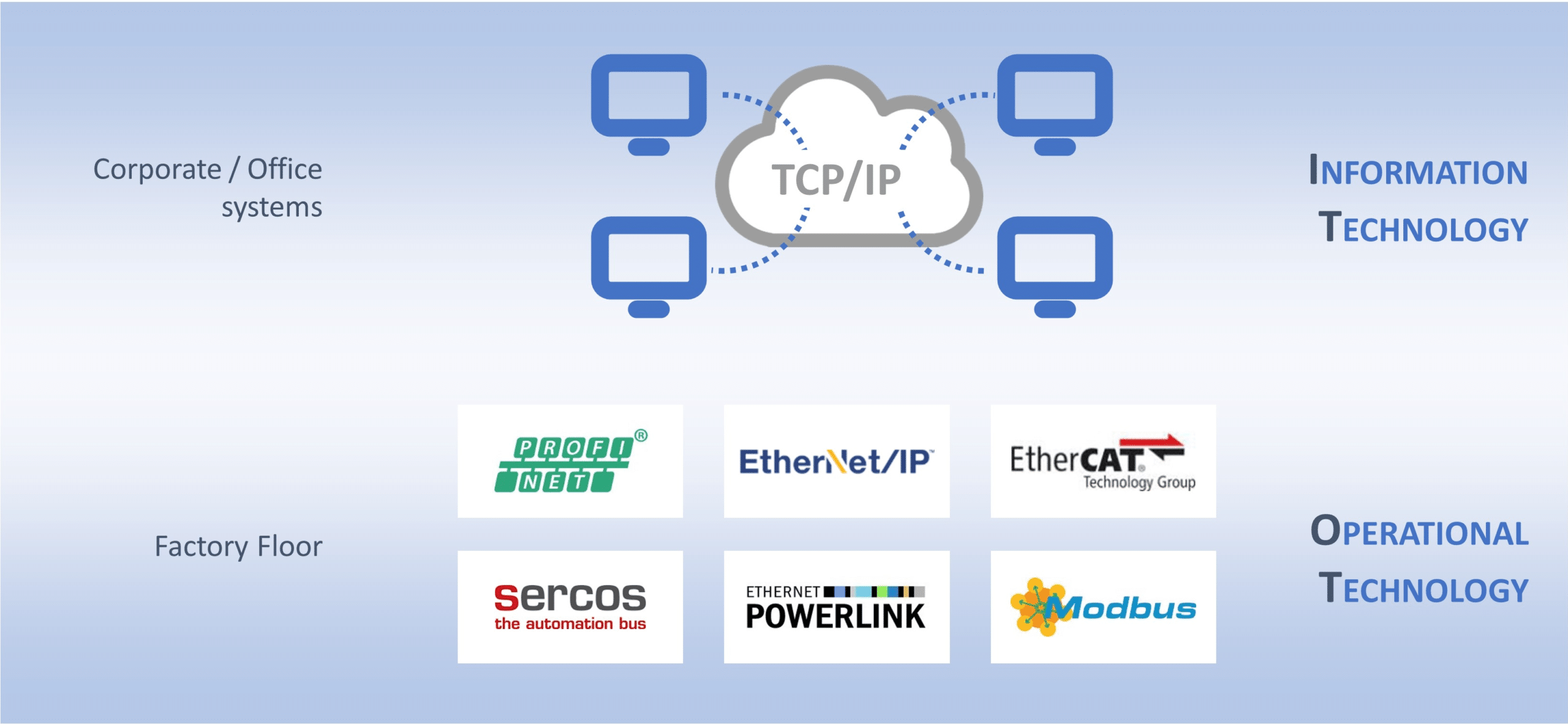

Industrial Ethernet – such as POWERLINK, EtherCAT, PROFINET and EtherNet/IP require a system that cannot be adequately addressed simply by changing a protocol library. This means, for example, that various protocols require changes and integrated resource management. Furthermore, the combination of real-time industrial communication together with the known fieldbus systems such as CANopen, MODBUS and PROFIBUS is arbitrarily difficult, since a transmission medium has been physically implemented which are fundamentally different here. Industrial Ethernet Networks are a development philosophy that in itself influences hardware and software architecture. The protocol library is an important element, but it requires support from the entire system to work efficiently. GOAL technology (middleware) is aimed at solving this problem and to ensure the highest level of availability through modular scalability.

The development goals of GOAL technology

- One hardware – Many communications options available.

- Ready-to-use modules with efficiency, change and resource management.

- Centralized configuration management

- Powerful options for fieldbus protocols and multi-protocol capability

- Portability to new applications. (eg CPU swap or migration between CPU/MCU families).

- Modularity and scalability.

- Sustainability (eg TSN, OPC UA) or Open for integration of additional modules. o Communication between cores.

- Notable reduction in development costs (Software).

- Significant reduction in the maintenance of different communication technologies.

- Substantial reduction in hardware costs. Currently, the basic version of GOAL offers extensive contents optimally adapted to individual needs: (Figure 1) They are basically divided into three fundamental areas that can be summarized under network term management, access/list management and configuration management. respectively. Network management contains extensive functions:

- PHY management: generic functions for managing PHYs such as duplex/link management, autonegotiation, etc.

- Sending/receiving Ethernet frames: Interfaces for sending and receiving Ethernet data in each layer of the ISO-OSI model.

- Switch management (switches): generic functions for managing switches, such as reading SNMP statistics, setting QoS functions, etc.

- Interface management: management of individual network interfaces such as activate/deactivate, statistics, etc.

- IP address management: Flexible handling of IP address assignment depending on the Protocol (for example, DCP with PROFINET or DHCP).

- HTTP Server: Embedded web server with template support.

- Command Line Interface: Integrated and extensible CLI to control, for example, change functionalities. In the "Access and management of the list, tasks" area, the following content is available by default:

- Locks.

- Mutual Exclusion (Mutex).

- Semaphores, binaries and counters.

- Linked Lists.

- Creation and control of tasks (Threads). The configuration management area plays a central role in configuring the necessary parameters within the environment of the respective CPUs/MCUs. This includes central administration of configuration variables, identification of module variables and IDs, function calls for value control and value changes, as well as loading and saving variables. Additionally, variables can be marked as temporary and locked. Another great advantage is the possibility of integrating the customer's storage system. Network protocols such as PTP, DLR, SNMP, IEEE802.1x, and RSP are widely supported.

Communication between Cores

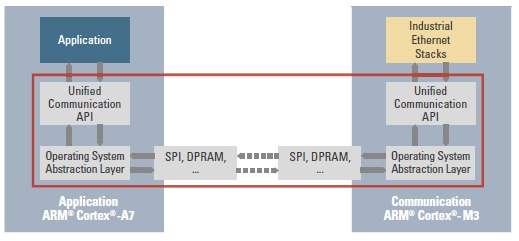

CPU/MCU are often used, which are not capable of meeting the needs of modern communication technologies, but are ideal for the particular use of the application. Development engineers feel at home with existing platforms and don't want to switch to entirely new platforms. For this case, GOAL offers the communication module between cores. (Figure 2) On this basis and depending on the availability of MCU communication protocols such as CANopen, EtherCAT, PROFINET, EtherNetIP, POWERLINK, MODBUS TCP can be used individually or as a multi-protocol solution. The configuration management module included in GOAL supports an extensive series of optional tools. The tools ensure the easy connection of the protocols for the respective use (EDS, GSD and ESI). Today, the decision of a microcontroller or a CPU platform (possibly also MCU/CPU families) is significantly influenced by the available software support.

The industrial communication middleware manages Ethernet communication in the network and industrial addresses with Ethernet-specific peculiarities, such as PROFINET system handling with network load tests. In the application, the industrial communication middleware offers interfaces for coupling to protocol libraries to easily handle multi-protocol solutions in a project. Addressing multi-protocol management becomes really effective through the proper management of variables in industrial communication middleware. This allows different applications and not just access to variables by the Protocol library. Industrial communication middleware is not intended to replace an RTOS (or OS) it is rather a complement to the OS and as a functional extension to Industrial Ethernet and its necessary specifications.

In non-OS applications, the combination with industrial communication middleware is a valuable building block for the system. The time savings and the advances in system security are considerable. In particular, in embedded systems, only the use of an industrial communication middleware can make the implementation viable. Industrial communications middleware is not just limited to communication – the application itself across the platform also benefits from the middleware. The greatest added value is achieved when the industrial communication middleware offers its inherent additional value from the beginning and during the development phase in order to be ready for future extensions and requirements.

The R-IN-Engine product family – performance plus energy efficiency

The GOAL middleware has already been adapted and applied in the new family of Renesas RZ/N1. With the introduction of this family of products, Renesas offers greater computing power for typical industrial communication applications. The high level of integration combines an Arm® Cortex®-A7 based application core with a real-time communication engine on a single chip. Multi-chip solutions of industrial controllers, industrial network switches and operator terminals can now be replaced, saving energy, by a simple SoC (System on Chip). In addition, RZ/N1 offers advanced industrial network performance with a powerful five-port real-time embedded switch and offers all necessary TSN endpoint features such as traffic shaping, time synchronization and frame classification/prioritization.

The RZ/N1 family consists of three products: RZ/N1D, RZ/N1S and RZ/N1L. RZ/N1D and RZ/N1S have an application block, and a communication block built into the same silicon. The application block of the RZ/N1D SoC comprises two ARM® Cortex®-A7 and is conducive to high-end uses such as network switches, PLCs, and gateways. The SoC is available in two types of packages, 400 BGA and 324 BGA. The RZ/N1S SoC application block contains an ARM® Cortex®-A7 and has been designed for mid-range applications such as Nano-PLCs and graphical operator terminals. RZ/N1S also comes in two packages, 324 BGA and 196 BGA. The communication blocks of the RZ/N1D and RZ/N1S are almost identical and, depending on the product option, offers three Ethernet in the smallest and five Ethernet ports in the largest package. While the RZ/N1D has 2 MB of internal memory and an external DDR interface, the RZ/N1D with 6 MB of internal memory is conducive to compact products with few external components.

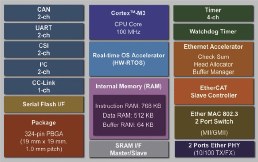

RZ/N1L does not have any dedicated application block, as it contains only a Cortex® M3 CPU. The idea behind this SoC is to offer a simple communication component comparable to the R-IN32M3 for customers who want to add a network function to existing devices. RZ/N1L is available in a 196 BGA package. The GOAL platform provides any connectivity between a multi-protocol communication processor (such as RZ/N1L or RIN32M3) and a traditional host MCU or in the highly integrated RZ/N1D and RZ/N1S SoCs, communication between the communication block and the application one. The GOAL interface is available for all platforms based on the R-In-Engine and developers can use the same software on multiple SoCs based on the R-In-Engine, R-IN32M3, RZ/T1 or the RZ family of products. /N1. There is already a development kit based on RZ/N1D or RZ/N1S and the GOAL is available and can be obtained from various dealers. The solution kit for the RZ/N1L will be available very soon. More information available at: www.renesas.com