Author: Lars Mickan, Renesas Electronics

The implementation of an Industrial Ethernet interface places certain demands on hardware and software and requires appropriate technical knowledge for its implementation. By using the new Renesas Stamp module solution, customers can successfully integrate hardware and software without specific knowledge of Industrial Ethernet protocols.

Why Industrial Ethernet?

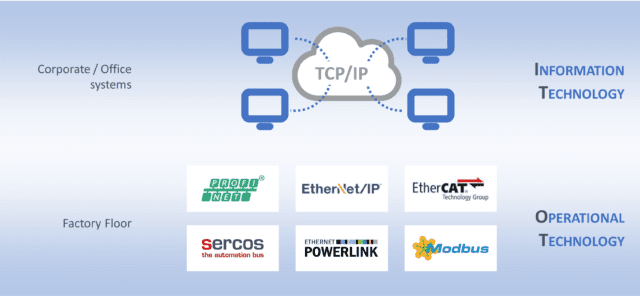

Industrial Ethernet protocols have been consolidated in the field of factory and process automation. The PROFINET, Ethernet IP and EtherCAT protocols together have a market share of 70%. The Industrial Ethernet market is growing by 20% every year and has already achieved a share of more than 50%.

Compared to traditional fieldbus technologies, the Ethernet-based protocol has the following advantages:

- Better performance and extended properties in real time, even with large amounts of data

- Consistent integration into IT systems

- Use of known and existing diagnostic tools

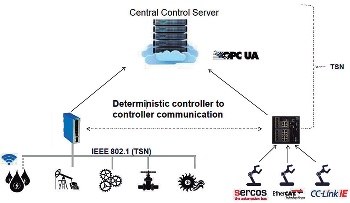

With the introduction of Ethernet-based communication protocols at the OT layer, the connection between OT and IT communication becomes easier and all the data from the field devices (OT layer) is available at the IT layer.

While this allows the use of all available data from the field, it brings new challenges such as real-time Ethernet and network security.

Real-time Ethernet communication should be based on the IEEE 802.1 standard and should cover the following topics, basically the different parts of the standard:

- ASrev: Timing and Synchronization for Time Sensitive Applications in Bridged Local Area Networks

- Qbu: packet preference

- Qbv: Scheduled Traffic

- CB: replication and removal of packages for security

- Qch: cyclic queue and forwarding

- Qci: filtering and surveillance by transmission

- Qcc: Transmission Reservation Protocol

Ethernet security is also an important issue because all critical parts of the automation plant are now connected and accessible via standard Ethernet just like in the IT world. Major end user organizations such as NAMUR have already recognized this issue and specified requirements (eg NE-153, IEC 62443 or VDI/VDE directive 2182).

The following sections will describe the solution that answers all of these challenges.

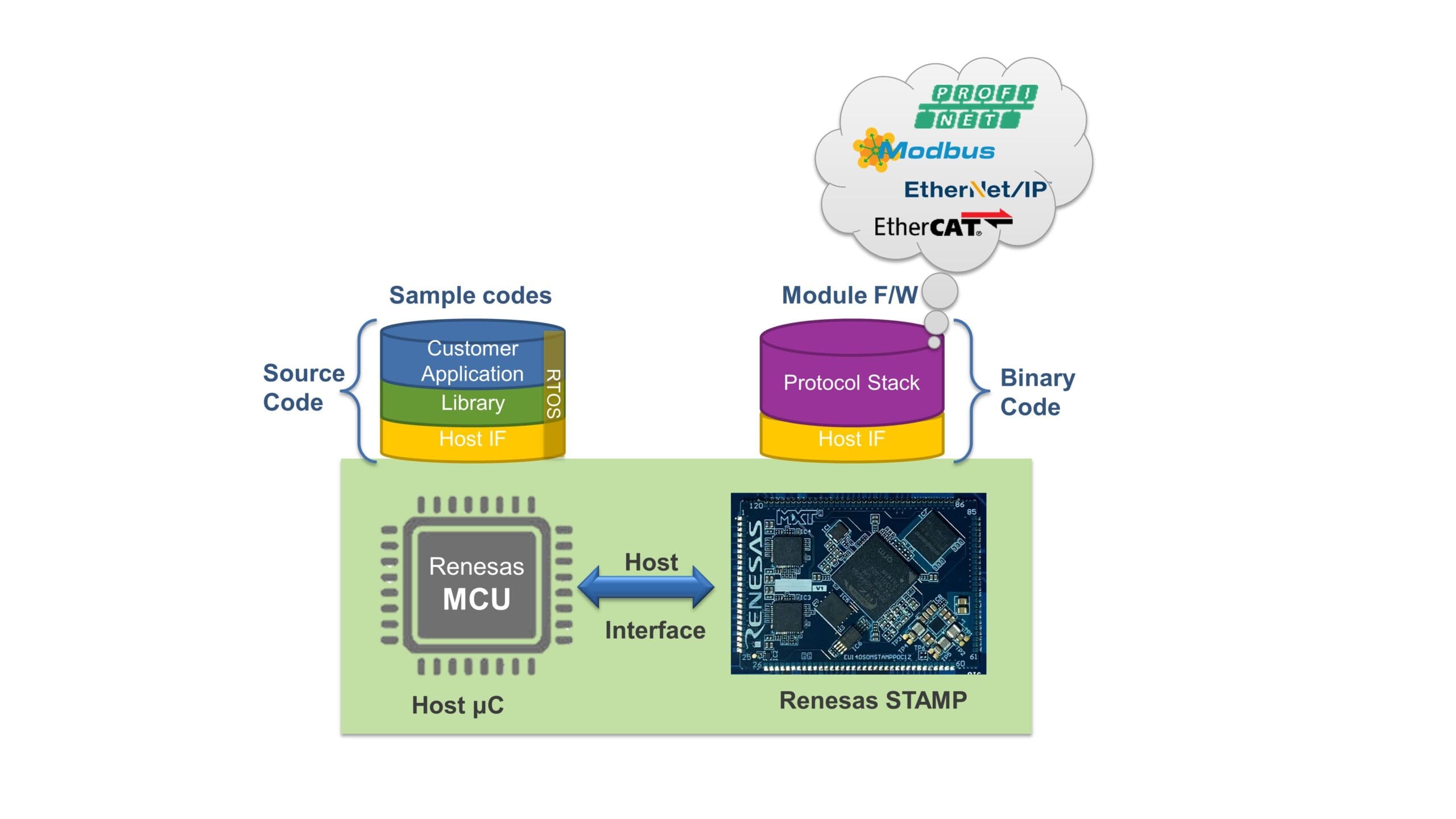

Separation of application and communication

To quickly take advantage of Industrial Ethernet, many device and system manufacturers are looking for ways to equip their products with a suitable interface. One problem is that although they have application knowledge, communication protocols are not part of their core competencies. Therefore, it makes sense to separate the application and communication technologies and connect them through a simple and generic interface. This allows the device or system developer to focus on building the application and not dealing in detail with data transfer.

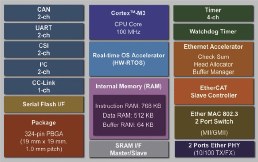

One such solution is the Renesas RZ/N2L based module (a Stamp module). It comprises a complete solution for the special requirements Industrial Ethernet (PROFINET, Ethernet IP and EtherCAT) with two PHY ports. In addition to the Industrial Ethernet protocols, the RZ/N2L device supports all state-of-the-art security features (such as advanced key management or isolated physical cryptographic operations) thanks to its integrated security cryptographic engine. The module can be assembled with a pick and place machine and reflow soldered like a standard SMD component. The necessary memory (RAM, flash) for the Industrial Ethernet protocols as well as the power supply (different voltages) for the processor and memory are available on the module.

In addition, the Renesas Stamp module solution can be used out of the box, as the software licenses for the protocol stacks are included in the price of the module. The module can be connected to any existing MCU via a simple SPI interface.

The simple software interface (API) allows data to be easily transferred from the application to the communication interface (input data) or in the other direction (output data). In addition, the software interface offers the following functions:

- Beginning of the Industrial Ethernet protocol and its structures

- Communication firmware and application software download

- Reading log files for diagnosis and troubleshooting

The software application examples demonstrate the functionality of the API and show users how to activate the Industrial Ethernet protocols. Sample projects are available and optimized for RX and RA of Renesas MCU.

Existing certifications allow for a plug & play experience

Another great advantage of the Renesas Stamp module solution is that, in addition to the software (protocol) certifications, the hardware has also been certified. Unlike software certification, these certification test results can be used for the final product. Since the software certification includes the application, it must be done with the end device that includes the application software.

The following hardware certificates are required and available:

- RoHS test

- REACH validation

- Measurement with respect to EMC

There is a Renesas declaration for RoHS and REACH, which is based on the fact that all components and materials used in the module have been tested to comply with the European Directive 2015/863/EU and the REACH criteria (No. 1907 /2006).

Acknowledgment of Compliance with the European Regulation (CE) Registration, Evaluation, Authorization of Chemical Products (REACH) No. 1907/2006, in force since June 1, 2007. (renesas.com)

To achieve CE compliance, the module hardware was tested according to the required standards for electromagnetic compatibility (EN 55011, EN 55024, EN 61000-4-2/3/4/5/6) in an accredited testing laboratory. .

All of these conformance tests that are now available enable the device manufacturer to shorten development time and costs while ensuring rapid product market entry. In times of agile development, these are important criteria that speak in favor of using a modular solution.

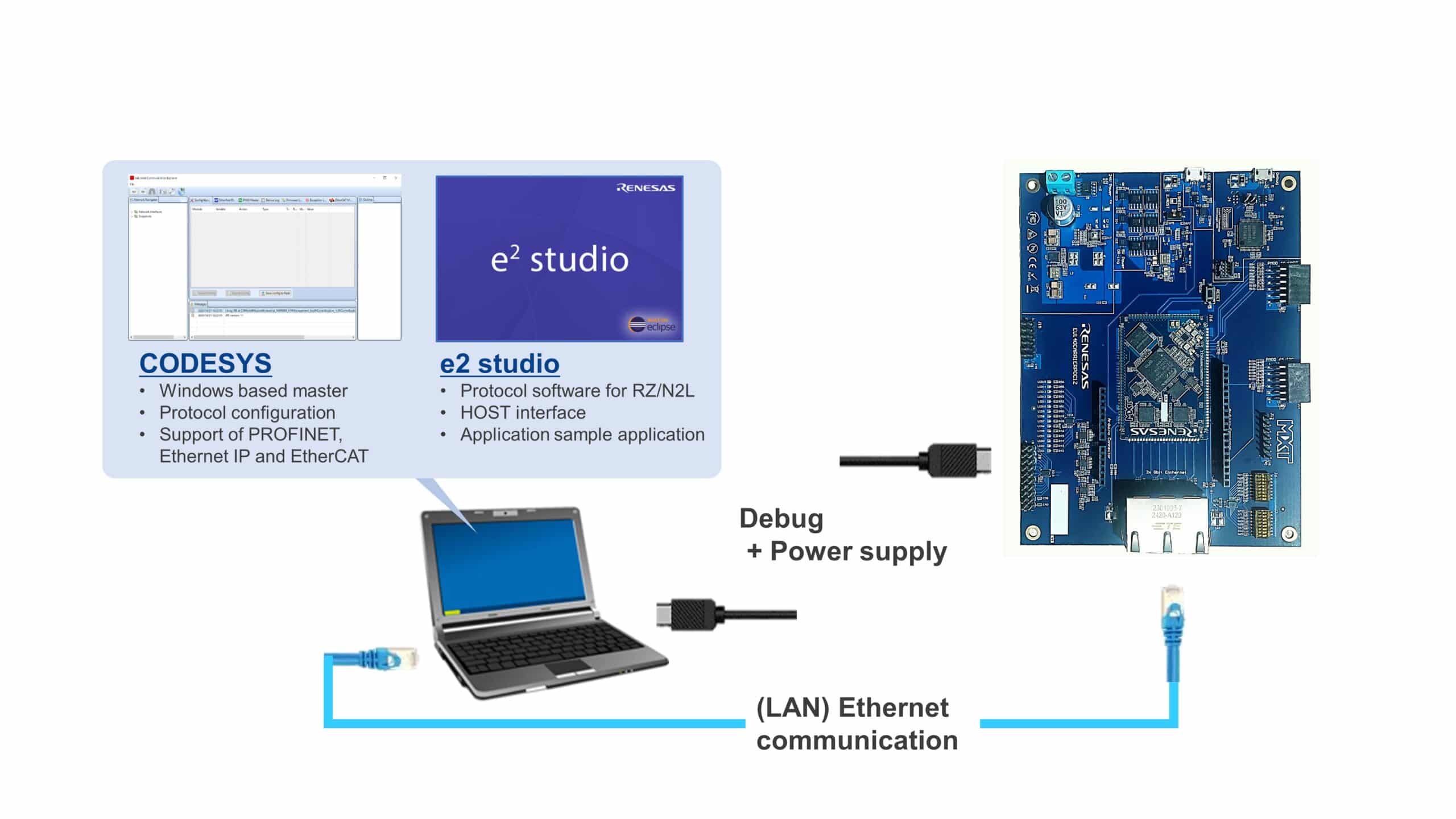

Toolkit and software examples for rapid and successful development

In addition, Renesas offers a kit version of the module solution, which consists of the Renesas Industrial Ethernet Stamp module on an adapter development board. This adapter board contains the standardized Arduino and Pmod interfaces, through which it can be connected to other Renesas MCU development boards such as Renesas RA and RX.