Presentation of the project

Centralized Traffic Control (CTC) is a form of railway signaling that consolidates decisions related to itineraries that were previously carried out by local operators or the train crew themselves. The system consists of a centralized command post from which track interlocks and traffic intensity are controlled in parts of the rail system designated as CTC territory. In the control panel of the CTC, the railway line is graphically displayed so that the controller can supervise the location of the trains in the territory under his control. On railways with more kilometers in length, there may be several command posts, but there may also be several controllers for each operational division. Command posts are often located near the busiest parking lots or stations, and their operational capabilities can be compared to those of air traffic control towers. In rail transport, traffic control ensures that trains traveling in the opposite direction on the same track cannot pass without special infrastructure, such as branch tracks and switches, to allow one of the trains to drift aside. Initially there were only two ways to organize the interaction of the trains: regulate the movement in advance or establish communication links between the authority responsible for the movement of the trains (the controller) and the trains. The railway companies would make these two control mechanisms official in a series of procedures called train running order operation, which were later partially automated through the use of automatic blocking signals (ABS).

The project has been carried out by a major Italian civil engineering and network engineering company, at the forefront of developing innovative services for the telecommunications, transport, energy and technology sectors. This company, which has 4000 employees worldwide and has an international presence, has carried out projects on practically every continent, from Europe to Latin America, the Middle East and Africa. To meet the demands imposed by the globalization of the market in terms of international presence, it currently also operates in Libya, the United Arab Emirates and Saudi Arabia.

System Requirements

For the choice of the company awarded the project, our client demanded the fulfillment of several requirements. The availability of modules with enough flexibility to adapt to the different needs and requirements of various places was one of the demands in terms of control installed on the ground. The use of intrinsically safe modules was essential to guarantee the absence of possible failures in any part of the network. For this, state-of-the-art devices were needed that could be quickly programmed using the latest programming languages.

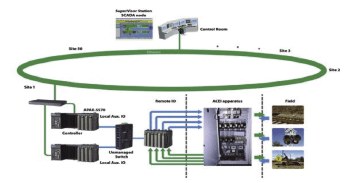

The solution proposed by Advantech consisted of fully integrating its products with the client's black box through the ACEI system (electrically controlled central maneuver). This centralized system controls points, signals, level crossings, maneuver signals and everything necessary for the operation of the railway station by sending signals from the surveillance equipment to the ACEI system. The signals are returned to the control room, where the data is displayed, through APAX modules.

Advantages

The customer installed several APAX and EKI modules in a cabinet next to the ACEI system near each station. Each cabinet contains two separate sets of APAX controllers in a redundant master/slave configuration. The master controller acquires the data, while the slave system remains in standby mode and, in the event of a failure, takes over control of the operation without interruptions to ensure continuous system availability. Advantech's APAX modules have enabled easier and more reliable edge station commissioning. In addition to providing the operator with a simple means of local connection to the station software via a personal computer, it allows querying of data exchange and station status. The tests have been carried out locally and the operator can directly verify that the field information is correct. As a result, the logic has been simplified. Modules can be hot-swapped and the system continues to function when servicing a single module, improving mean time to repair (MTTR). APAX's modularity has allowed the customer to create different devices for different installations in the same facility. This also makes it possible to expand the system and offers the possibility of adding I/O modules to make measurements in the field, for example, the current that a motor generates (diagnostic data). Software reuse helps reduce new software development costs with an easy-to-use programming environment and plug-and-play functionality.

As the APAX system is based on PC logic, it allows the configuration of the single system to be automatically transmitted to the control room.

With a reputation for high quality and availability, Advantech's devices have been used in Italian railway signaling for years and have helped deliver on-time service. While Advantech's product portfolio has enabled our customer to use the most appropriate architecture based on the application, the local presence has enabled the customer to collaborate with local engineers to determine the most effective configuration and has helped maintain a relationship fluent in all stages of the process.