Introduction

LEDs are now firmly established in an ever-widening range of applications. They offer greater efficiency and reliability than traditional bulbs, lower costs and a smaller size.

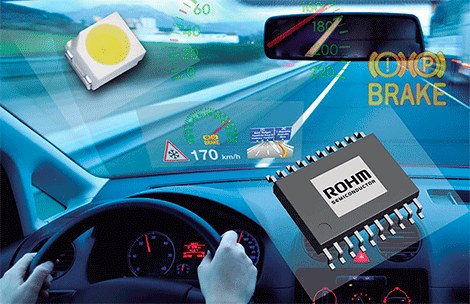

In some markets, including the automotive sector, LEDs are mainly used in safety-critical applications, so they need to provide high reliability and error detection. It is to be hoped that the relevant standards will continue to develop in other areas as well – towards greater reliability. In some cases, this has already been developed by new laws. Another trend is the increasing demand on the adjustability of the brightness and color of LEDs. Thus, for example, a high mutual match in the color of the LEDs may be needed in precise regulatory procedures.

Discrete LED Driver Solutions

A typical LED application contains a microcontroller and a regulated power supply. Depending on the type of application and type of LEDs implemented, it can vary considerably.

In a simple application, the microcontroller can directly drive the LEDs using discrete switches and current limiting resistors which can have many disadvantages.

The large number of external components requires a large amount of space on the board and affects reliability as the number of components that may be at risk is large.

The microcontroller may also not have enough pins to drive all the required LEDs. In addition, the software expense is high since the microcontroller must actively control the LEDs at all times.

Control of LEDs with a current setting resistor is also imprecise because in this way, only the optimum power can be set at a given operating point. However, the application may be subject to significant fluctuations in supply voltage and temperature, so the color and brightness of the LEDs can vary dramatically. Current sensitive control is not easy to implement – in contrast, Pulse Width Modulation (PWM) is. However, the use of discrete switches for a PWM solution can cause electromagnetic interference (EMI).

The most important point, finally, is the fact that failed LEDs cannot be easily detected through discrete control, which can be critical also if the LEDs are deployed in safety-critical applications. Therefore, failing LEDs will need to be checked by the microcontroller.

Integrated LED control solutions

To overcome these limitations, highly integrated devices have been shown to combine several functions. A simple but effective solution is to use a multi-channel constant current driver that is controlled by an SPI, this is offered by the ROHM BD18378EFV-M. The microcontroller uses a serial SPI bus to program the LED driver. On the other hand, the LED driver implements and integrates the analog functions that are needed to supply the LEDs with a constant current. In addition, diagnostic functions can be integrated.

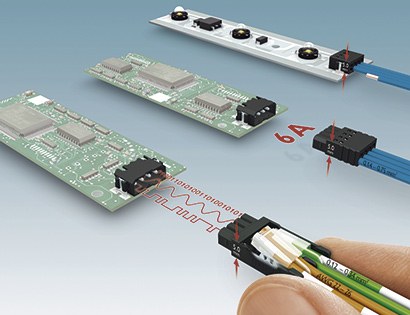

The SPI bus can be easily implemented with any microcontroller. Only four pins on the microcontroller are required for bi-directional communication with the LED driver. If many LEDs need to be controlled, multiple drivers can be controlled by daisy-chaining. Thus, 20 or more controllers can be placed in cascade; the upper limit is only set for the time required for programming. Once programmed, the controllers do not need any further communication apart from PWM functionality, and any potential error messages. Therefore, the expense for the system is reduced.

Since all of the components required to drive multiple LEDs with constant current are integrated into the driver, a dramatic reduction in components is achieved. Without the impact of changes in supply voltage or temperature, all connected LEDs are powered with a constant current. This current can be adjusted by using the registry settings. Only a single external resistor is required to adjust the base current.

Failure of this current resistor is unlikely, but a good controller can even detect this failure, and in such a case can switch to an internal reference. Since the controller regulates the current and no voltage is switched, electromagnetic disturbances are greatly reduced.

Many LED drivers are designed for accuracy as current sinks. This requires that the LEDs be connected to a suitable power source. For efficiency, this power supply is usually implemented with a power management device. The power supply may – but need not – also power the controller. If the device tolerates a higher LED supply voltage, it is beneficial for its robustness and the flexibility of the system.

The LED driver can supply high current to a large number of LEDs. Since the supply voltage of the LED can be high, a high voltage drop can arise in this device, which can generate considerable heat loss. For this reason, most constant current drivers provide a lead-out chip for cooling and are equipped with a thermal shutdown feature to protect against overheating. Some products also include pre-warning so the controller can initiate corrective action before problems arise. The chip must, of course, be connected to a large enough heat sink (usually referred to as the ground plane of the circuit board or module case).

The maximum values of voltage and current are generally responsible for the constant current driver being able to control a maximum of twelve dozen LED channels. If more LED channels are needed, these can be supplied by a daisy chain configuration of multiple drivers controlled via SPI. However, it is also conceivable for one channel to drive multiple LEDs if they all need the same current and the voltage reserve is large enough.

The color of an LED can vary greatly depending on the current intensity. Therefore, for LED dimming it is common to use the PWM method in order to keep the current (and therefore the color) constant. Luminous brightness can vary this way to accommodate changing light conditions, or, for aesthetic reasons, you can smoothly turn the LEDs on or off. If it makes sense, each group of LEDs can be equipped with its own PWM controller.

In some cases, further fine tuning of the LED currents may make sense. It may, for example, be important for aesthetic reasons that several LEDs that are arranged closely together emit the same brightness. A bar chart is a good example of such an application. In such a situation, it would be necessary for the LED currents to be able to vary in less than 1% increments in order to compensate for differences in brightness between the LEDs. However, this assumes that the power requirement of the individual LEDs is known in advance (by "binning" during their manufacture).

Another example where a fine power adjustment would be useful is RGB LED based color lighting. By finely varying the currents that allow the various LEDs to be controlled, a wide range of colors can be achieved for effect lighting. A smart LED driver like the BD18378EFV-M therefore offers both PWM and analog options for current adjustment.

The failure of an LED can be detected based on the voltage applied to the driver for the individual channels. If the voltage of the respective channel drops, an open circuit is assumed at the LED. On the other hand, if the channel voltage increases to the LED supply voltage, a short circuit in the LED is assumed. In both cases, the microcontroller must be informed through the SPI of the failure, in order to cut off the power supply for the affected LEDs. However, when a short circuit is detected, the driver must take into account changes in the supply voltage or forward voltage of the LED due to temperature or selected power, as well as due to different LED supply voltages.

Rohm Semiconductor LED Drivers

With the introduction of the M-BD18378EFV, ROHM Semiconductor has further expanded its portfolio of LED Driver ICs for automotive applications.

The product is AEC Q-100 qualified, and therefore without restriction suitable for the automotive market in Europe and the US. ROHM's orientation towards quality is a guarantee of high reliability for customers.

For evaluation purposes, ROHM Semiconductor offers samples and demo boards, as well as PC-compatible graphical user interface software with example programs.