Cadlog, founded in 1985, is the largest European distributor of solutions for electronic design and production. We are still by your side, now more than ever.

Electronics is acquiring, day after day, a greater role in our society. In this context, Cadlog -official partner of Siemens Digital Industries Software in Spain- presents itself as the ideal technological partner, which offers the most advanced software solutions to companies seeking to increase their competitiveness in the complex electronics market. Cadlog also supports designers, OEMs and EMSs. The group provides support to the entire electronics industry and guides companies in optimizing workflows and increasing performance throughout the product life cycle, from the design phases to manufacturing. All of them, phases that require a high level of precision and efficiency, only possible with the best tools.

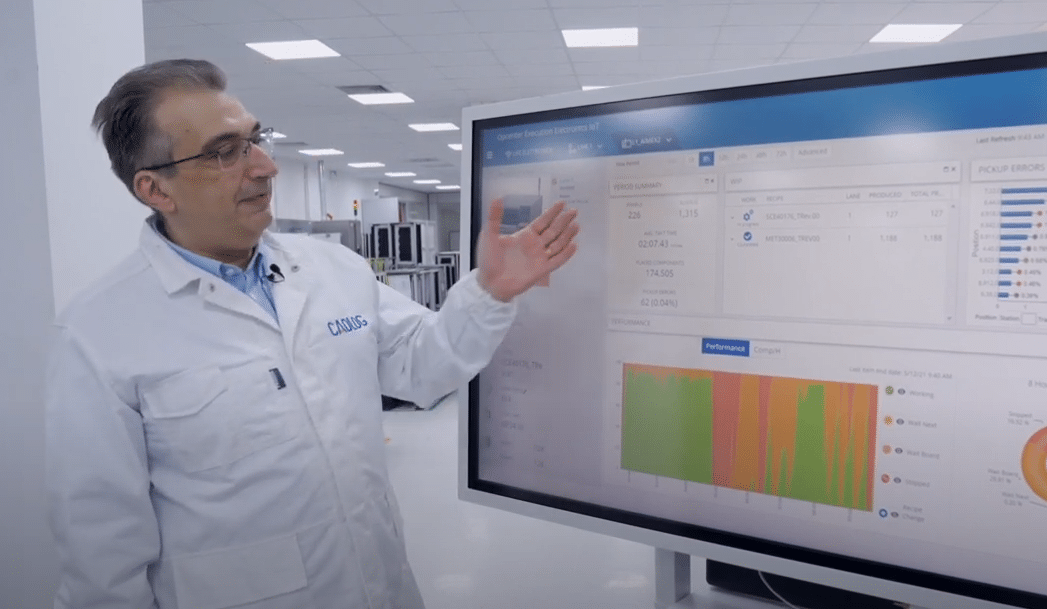

“Cadlog is the partner of all companies that design, produce or develop electronic products”, sums up Alessandro Balboni, Product Manager in the field of Manufacturing Operations Management. "Being the technological partner of the electronics industry means helping our customers choose the best technologies to be as efficient as possible in their market, be innovative at the best cost and be competitive in a context of international competition."

“Cadlog is a special company,” says Filippo d'Agata, CEO of the Cadlog Group. “It is not easy to find a partner who knows the process from design to production. Cadlog has extensive experience and knows the problems in the field”.

Our value lies in knowing how to assess customer needs and respond to their demands for the digital transformation of your company. We support manufacturers in optimizing the New Product Introduction (NPI) process from the early stages of development through to the manufacturing phases.

A challenging context

The industry must adapt to the current socioeconomic context, characterized by a strong digital trend, the Internet of Things (IoT) and changes in consumer habits. This panorama entails the need, for the electronics industry, to adopt the model of Industry 4.0, consisting of the digitization and automation of processes. In this area, it is very important to digital twin or digital twin, a virtual and highly faithful representation of the product or manufacturing process.

Likewise, there is the question of the lot-size-one or the manufacture of small batches of different products. The latter is a major problem for small and medium-sized companies with assembly lines. From the manufacturer's point of view, the main idea of lot-size-one means being able to manufacture any product, in any variant, quantity, sequence order, production line and time. The trend, except in the case of consumer goods, is to receive orders for a limited number of units, ranging from a few tens to a few tens of thousands. Therefore, the complexity lies in the need to remain competitive by responding to a wide variety of requests.

Alessandro Balboni stands out the crucial importance of data analysis in these cases. “The success of a product is related to the flexibility of the company and its ability to adapt efficiently, but it also has a lot to do with the analysis of the data,” he says. The future for companies in the electronics sector will depend on their ability to collect and interpret data that allows them to perform predictive analysis of production.

Cadlog Group Key Figures

• 4 offices in Europe and operations in 13 countries.

• More than 1.400 active clients.

• More than 15.000 licenses sold for the design of PCBs.

• Technical support available in 6 languages.

• More than 150 CMS lines installed in 6 countries.

• 24/7 production support.

• Around 15 million euros of turnover.