HIOKI's new PW8001 power analyzer sets a new industry standard with its unmatched accuracy, providing the best solution for high frequency and power measurements. This allows for peak efficiency measurements from state-of-the-art SiC and GaN based applications to complex multi-engine powertrain power analysis.

Ideal for SiC and GaN applications

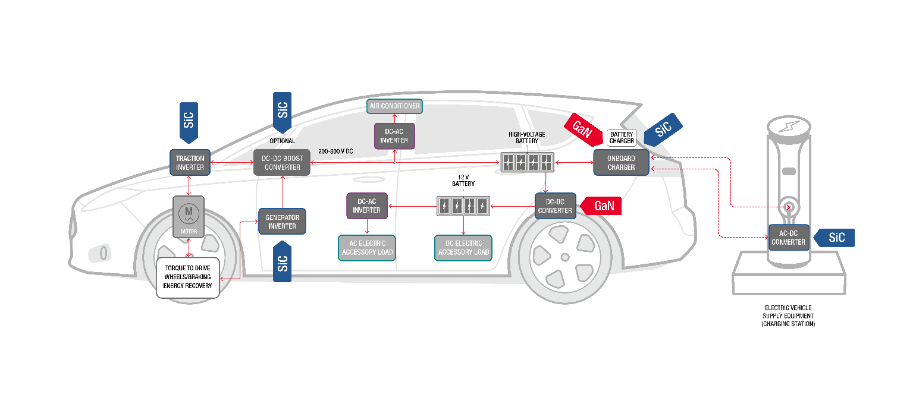

The use of SiC and GaN semiconductors for all kinds of power converters is increasing strongly. But why is the use of SiC or GaN semiconductors so interesting? SiC and GaN semiconductors make it possible to further improve the efficiency of power converters while at the same time reducing the size and weight of converters. An added benefit of downsizing is that it creates more flexibility in PCB design in confined spaces. But, as always, there is also a downside. SiC and GaN semiconductors operate at higher switching frequencies than conventional Si-based semiconductors and generate more noise and require a power analyzer with higher bandwidth and better resistance against external noise. The Hioki PW8001, in combination with Hioki current sensors, is the perfect choice for this challenge. Industry-leading power accuracy for DC and at frequencies of 50 kHz and above, combined with the unprecedented common mode voltage turndown ratio (CMRR) for the PW8001 and Hioki current sensors, ensure extremely accurate and unaffected measurements. , even in extremely noisy environments.

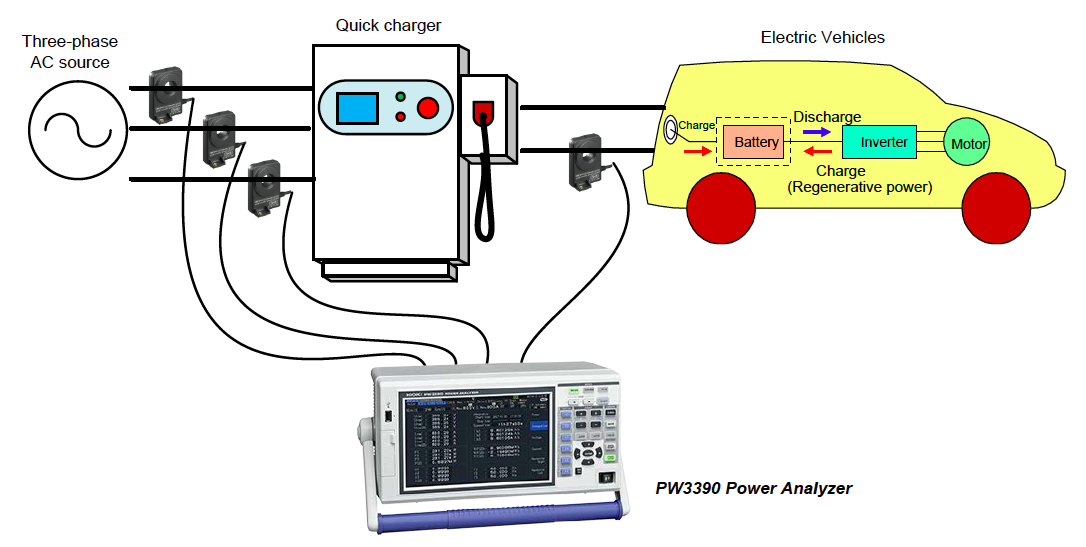

When you are developing a highly efficient wireless charger or inverter motor drive for EVs or drones, the accuracy of your measurement system is critical. You must be able to measure the smallest improvements in efficiency. This means that your power analyzer must measure both DC and high frequencies like 50 kHz or even higher as accurately as possible. The PW8001 is perfect for this type of work.

Combined with the U7005 high-precision input module, which has a 15MS/s sampling rate and 18-bit A/D conversion, the PW8001 offers 0,05% power accuracy for DC, 0,03% at 50/60 Hz and a best 0,2% on the market at 50 kHz.

Power Analyzer for one thousand five hundred V DC CAT II

The trend towards more powerful solar farms has led to an increase in the working voltage. Today fifteen hundred V DC has become the standard. In addition to this, solar farms are combined with local storage solutions for grid balancing purposes or to provide round-the-clock power. Another area where higher voltage is becoming more common is the electrification of heavy trucks and buses. While regular electric cars use XNUMXV DC or XNUMXV DC systems, the transportation field moves to XNUMXV DC to increase system power and reduce charging time.

To provide a power measurement solution for these new technological trends, Hioki has developed the U7001 High Voltage Input Module. With the U7001 Hioki is the first on the market with a 8001 Vdc CAT II benchtop power analyzer. This classification allows the PWXNUMX to be used for development and production testing of solar power conditioners, drive trains, and fast-charging solutions for heavy-duty electric cars with a system voltage of more than XNUMX VDC.

Four Motor Drive System Analysis

Currently, drones are used in a wide range of applications, such as making videos from a bird's eye view, surveillance, inspections in dangerous environments or the delivery of packages. AED drones, which are equipped with a defibrillator, can even save lives because they can arrive before an ambulance at emergency sites in frequented places such as festivals or urban centers. Other companies are still developing bigger and more powerful drones like taxi-drones.

For all of these drones, powertrain efficiency and reliability is extremely essential, as every increase in efficiency will lead to an increase in range. The PW8001 with the four-motor evaluation option is the ideal development tool for drones and other four-motor drive systems such as high-performance electric cars, in-wheel motor electric buses, and industrial robots. It lets you examine the performance of all four engine drives simultaneously, which makes powertrain balancing much faster and easier and will result in more efficient and reliable designs.

Automatic correction of phase changes

Throughout the design of helicopter boosters for (H)EV or active power factor correction systems for the grid, measurement of the power loss of reactors and transformers is essential. The inductive nature of these components makes it quite difficult to measure accurately, especially at high frequencies. One of the reasons for this is that voltage and current must be measured precisely in time in order to measure active power. However, current sensors will always have a time lag. Consequently, in order to be able to measure the loss of a reactor or transformer accurately, the time delay of current sensors must be eliminated over the entire frequency range.

For such reason, Hioki has incorporated a phase shift correction function as standard a few years ago, which has now been enhanced to a simple plug-and-play function that does not require manual input like the automatic shift correction function. of phase (APSC). This unique new feature is available for the first time with the new PW8001 power analyzer. The APSC function ensures unmatched performance for high frequency transformer and reactor loss measurements.

In order for the APSC function to work properly 2 things are required:

• the current sensor with a known constant time difference

• the power analyzer that is able to compensate the time difference

As the only power analyzer manufacturer to also design and build current sensors, Hioki is in a unique position to optimize current sensors for APSC.

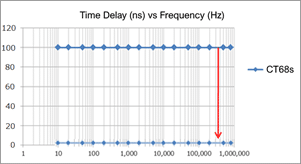

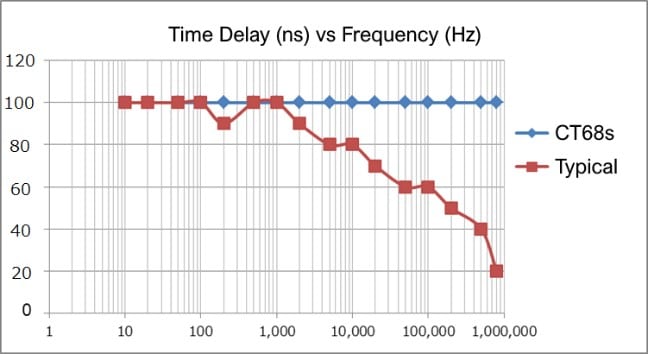

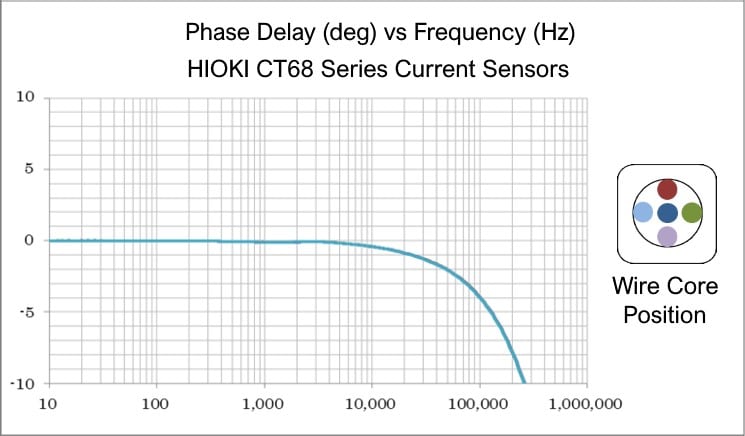

The Hioki CT68 and CT69 series current sensors have been designed to achieve a constant time difference over the entire frequency range, as shown in figure 1.

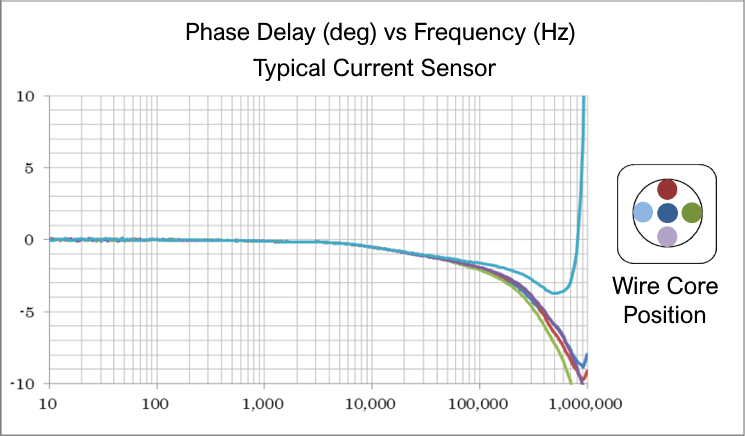

Due to this unique feature, the PW8001 can compensate for current sensor time delay, regardless of the frequency it is measuring. Other current sensors on the market tend to be designed with a focus on low phase shift at high frequencies. As a consequence, these current sensors are not going to have constant time delay over the entire frequency range. This is illustrated in figure two, where the time difference of a comparable sensor available on the market is shown.

Since the time offset of the comparable sensor changes between 100ns and 20ns, this makes it clear that this design makes this sensor unsuitable for phase shift correction, as the power analyzer cannot compensate for the time offset. at each and every frequency it measures.

Also the positioning of the conductor in the current sensor can influence the accuracy of the measurement. This is illustrated in figures three and four.

In figure three, each and every curve is precisely on top of each other, which shows that there is no impact on the phase delay due to the driver's situation.

Exactly the same tests have been carried out with a comparable current sensor and the result is shown in figure four.

Figure 4: I differ from phase and situation of the cable core of HIOKI CT68

The results are very, very different. In such a case, the location of the conductor influences the phase difference at frequencies above one hundred kHz, and will have an impact on the general accuracy of power measurement at high frequencies, such as with the use of SiC and GaN semiconductors. .

Maximum flexibility

The increasing difficulty of energy applications, such as integrated solutions for renewable energy with local storage, grid connection and electric car charging, require an increase in energy channels to be able to examine the active energy behavior of a system. .

The PW8001 with its eight channel modular power inputs in one instrument, free choice of U7001 and U7005 high voltage input modules and over range of current sensors from 20A to 2000A, offers you the possibility to compose your solution "custom" power measurement.