Microelectromechanical systems (MEMS) incorporate nanotechnology into electromechanics. Miniature mechanical and electromechanical elements under the control of integrated microelectronics are encapsulated in a small vacuum chamber to form complete systems. This is how the definition of MEMS goes. A number of functional elements like sensors and actuators can be executed as MEMS transducers, devices that convert energy from one form to another. In the case of microsensors, the device transforms a mechanical signal into an electrical signal. The possibilities offered by MEMS technology in terms of reducing the size and cost-effectiveness of the production methods used open up new fields of use. One of these areas is timing with MEMS-based resonators, tiny structures that vibrate at high frequencies. This article provides an overview of the devices and technologies of the industry's leading manufacturer SiTime.

Traditional oscillators and resonators

A resonator is a device that oscillates at certain frequencies, called eigenresonant frequencies, with a greater amplitude than at other frequencies. These oscillations can be of an electromagnetic or mechanical type, generating waves or specific frequencies exclusive to a signal. Most widely used traditional crystal oscillators use the mechanical resonance of a vibrating crystal of piezoelectric material to create an electrical signal with a very precise frequency, which is used as a clock signal for microprocessors or to stabilize signals for radio frequency systems.

Quartz crystals are made for frequencies ranging from kilohertz to megahertz. Timing of digital electronic circuitry was not complicated, typically taking a Pierce oscillator driven by the piezoelectric quartz crystal resonator and providing an oscillating signal that, after filtering, could be used for most timing tasks. . There are also oscillators that use piezoelectric ceramic resonators inside instead of quartz crystal.

Traditional quartz oscillators require custom machinery to cut, grind, and laminate the resonator crystal. The manufacturers are experts in manipulating them so that they achieve the necessary frequency and provide stability for 20 years. However, they generally do not have the necessary experience in analog electronics, so they are forced to acquire the analog mold. If devices are purchased from external vendors, significant additional costs could arise in order to achieve high quality levels.

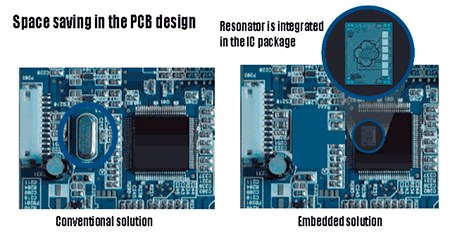

The complexity of the oscillator manufacturing process translates into higher investment, higher manufacturing costs, longer delivery times and more quality problems. On the other hand, semiconductor clock manufacturers did not have experience in the special way of encapsulating quartz crystals that require a vacuum-sealed ceramic package to preserve a high Q factor. Keep the two packages for resonator and electronics separate analog had a negative effect on the market need to minimize component size.

MEMS Resonators – SiTime

For the last few decades, quartz crystal-based oscillators, clock generators, and resonators have been the main reference timing components in electronics since no real alternatives existed. A new technology has recently emerged that offers the first devices in which the MEMS structures are integrated in the same package with the analog circuitry. MEMS resonators are connected to specific circuit blocks in analog integrated circuits and are driven by electrostatic excitation. A MEMS generator is used to fit the electrostatic transducers embedded in the MEMS mold.

The resonator sustain circuit causes the resonator to initiate a sensed mechanical oscillation, and the analog oscillator template can provide multiple clock outputs from a single compact semiconductor package.

SiTime, an analog semiconductor company whose MEMS technology traces its roots to Bosch and Stanford University, offers solutions that are replacing traditional quartz crystal-based oscillators, delivering higher performance and reliability at lower cost. SiTime has introduced a combo-chip solution that stacks the MEMS structure on top of a standard CMOS die to supply all of its timing signals.

A key advantage is the ability of the MEMS chip to set multiple clock frequencies on a single chip as factory defaults. The combined MEMS-CMOS solution offers important advantages such as a smaller footprint and less complex chips.

Their products can also be programmed at the factory and offer direct replacements for quartz oscillators without any design changes. The programmable architecture allows for flexible product design and short lead times, while offering a footprint reduction of up to 85%.

Designers can also order the Time Machine II programmer to program SiTime oscillators in-house for rapid prototype development. SiTime has combined the MEMS and analog electronics into a single mold so it is no longer necessary to separately encapsulate the resonator and analog electronics.

As can be seen in the image, the device provides temperature compensation to minimize frequency drift as temperature varies, output drivers, and a one-time programmable memory. SiTime has been able to design kilohertz devices with drift as low as 500 fs, stability as low as 0,1 ppm, and very low power consumption (700 nA). Programmable parameters include, for example, rise and fall times to reduce electromagnetic interference, improve deflection or drive any type of loads, a frequency with an accuracy of up to six decimal places and stability, temperature and signaling level (LVPECL or LVDS ).

Advantages of MEMS resonators over conventional crystal oscillators

The biggest enemy of MEMS oscillators is moisture that can condense on the tiny resonator during operation causing changes in its frequency. The first phase of the MEMS process solves this problem by sealing the MEMS cavity in silicone at extremely high temperatures and thus making it impossible for moisture or dispersed gases to develop.

The MEMS process technique waits for the last step to place a glass lid on a wafer at relatively low temperatures. Bosch and SiTime are considered the only two MEMS manufacturers to employ this early MEMS approach.

Still today, the strongest argument for continuing to use conventional quartz resonators is their low price and predictable thermal stability (see the red curve on the image). The characteristic of a MEMS resonator is typically close to a vertical line, so for oscillators based on these types of resonators temperature compensation circuitry is essential.

Originally, SiTime MEMS resonators had a frequency stability variation of 30 ppm/C, which actually corresponds to 4000 ppm over the full operating temperature range of -40 –85 ºC before compensation. temperature control in analog electronics reduced it to 0,1 ppm, while conventional quartz resonators typically achieve 0,4 ppm/C. Newer TempFlat MEMS devices differ from previous MEMS oscillators, being the first MEMS resonators to outperform quartz resonators without temperature compensation circuitry. The features shown in the image are based on actual measurements.

The image compares quartz oscillators with silicon MEMS timing devices from SiTime.

Customers can request any combination of frequencies, voltages, and frequency stability (PPM) in a number of industry standard packages. SiTime oscillators offer any frequency within the operating range with precision to 6 decimal places.

With custom frequencies, designers can also increase system performance (microprocessor / FPGA applications) and reduce bit error rates (Ethernet applications).

Since the devices are manufactured using standard CMOS silicon techniques, they are easier and cheaper to manufacture than crystal oscillators that require special packaging and production techniques. And since the manufacturing process involves fewer parties involved, costs are minimized as is the time for a first sample.

Customers not only benefit from a lower price, but also from shorter delivery times that make it possible to reduce investment costs. As MEMS devices offer more features (eg, programmability), design costs also drop. Since the reliability is higher, the final product will be a great brand value.

SiTime Highlights

SiTime's SiT15xx series oscillators are the smallest size oscillators available for 32 kHz timing applications. They combine a MEMS resonator with a PLL fractional-N synthesizer and different dividers to provide a frequency from 1 Hz to 32,768 kHz.

Components with a small package of 1.5X0.8×0.55 m have a stability of 100 ppm, low consumption (0,75 uA) and excellent resistance to shock and vibration. Some members of this family are fixed frequency (32,768 kHz) devices, while others are programmable frequency and operate on 1,2 to 3,6 V or 2,7 to 4,5 V power respectively.

The first oscillator released as early as 2008 is the lowest deviation programmable oscillator for the SATA, Fiberchannel, Firewire, Ethernet and PCI Express markets. The SiT8003XT is the thinnest programmable oscillator with a typical height of 250 microns. This product is targeted at the field of portable applications such as smart cards, flash storage devices, and mobile phones.

As a 8920% pin-to-pin drop-in replacement for existing quartz oscillators, SiT100 achieves +/-25ppm frequency stability over the full temperature range of -55ºC to 125ºC.

SiTime's range of MEMS-based silicone timing products offer solutions for a wide range of applications. As direct replacements for quartz devices, SiTime oscillators and clock generators are successfully replacing silicon-based quartz timers. More technical information and examples can be requested from the author.