Introduction

Current sense resistors are used in various applications and devices, including motor drive circuits, for over-current protection, and to detect the remaining battery level. And while they have been widely adopted in the PC and industrial equipment markets, in recent years demand has risen sharply in the automotive sector with the proliferation of hybrid and electric cars – and in the industry as a whole, due to increasing computerization and sophistication of vehicle systems.

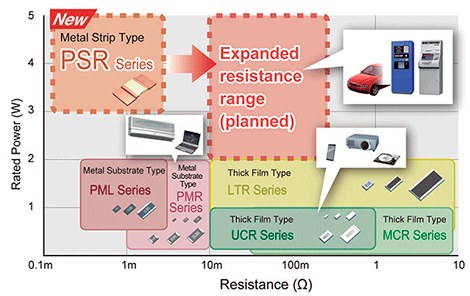

To meet this growing need, ROHM has expanded its family of automotive low-ohmic resistors to include high-power, compact varieties, ultra-low-ohmic models that minimize circuit power consumption, and high-precision products that offer TCR ( Resistance temperature coefficient) higher, suitable for harsh temperature environments. (See Figure 1).

Important automotive applications (See Figure 2):

motor drive circuits

DC/DC converter output lock

Battery charge monitoring circuit / remaining battery level detection

Resistance trend for current sensing

Low ohmic resistors used for current sensing are normally connected in series with the load, and the potential difference between the two terminals, measured by an IC, determines the amount of current flow. In order to increase the measurement accuracy, a higher resistance value (within the low resistance range) is recommended. However, this will lead to more heat generation and losses, so it is essential to find the right balance.

On the other hand, in recent years IC performance has improved drastically, allowing higher current sensing accuracy by measuring even smaller potential differences. This allows the use of lower resistances, capable of sensing even the largest currents with lower power consumption than existing products. ROHM developed the PSR series of low ohmic resistors that withstand large currents of over 150A.

Low Ohmic Resistor Technologies

Surface mount low ohmic resistors are typically classified by material and construction. The most popular type is based on thick film technology. Another option is the metal strip or substrate type that uses a metal alloy for the resistive element. Although the selection of the type of resistor to use will depend largely on performance requirements, thick film resistors are typically offered in the milliohm range, while metal and substrate strip resistors are available in the low milliohm range. resistance of several milliohms, and are characterized by a higher power rating. (See Figure 3).

For chip resistors, 2 types are offered, depending on where the electrodes are mounted – in the short part (standard type) or in the long part (long lead type). Long-terminal chip resistors generally provide greater connection reliability and thermal cycling characteristics. Additional benefits include better heat dissipation properties and higher power ratings compared to conventional short lead products. (See Figure 4).

As the electrode coating, nickel-tin is normally used. However, copper is an option when the resistance measurement is stable and resistance-temperature enhancement characteristics in the low resistance range are considered.

Low resistance based on thick film technology

The main stage of creating thick film chip resistor devices is pattern formation via screen printing. Screen printing techniques used to form the resistive element and electrodes onto the aluminum substrate.

For low resistance models, although a low ohmic resistive element material is used, a variety of factors must be considered to achieve optimum design, such as temperature coefficient susceptibility and temperature based cycling characteristics. in the formation of the electrode material and the resistive element / electrode thickness compared to conventional products.

ROHM, a pioneer of thick film chip resistors, developed the industry's first thick film chip resistors and offers an expanded range, using industry leading technologies proven over many years.

For the automotive market, which requires high connection reliability and power rating, ROHM offers the LTR long-terminal chip resistor series. The long terminal design provides increased connection reliability and superior temperature cycling characteristics. In addition, the excellent heat dissipation characteristics result in a higher power rating than conventional thick film resistors (ie 1W in the 3216 size).

ROHM's standard low ohmic line includes the MCR series of general purpose thick film chip resistors, available starting at 47mΩ (as well as an extended resistance range starting at 11mΩ).

The UCR series is also available, which features a larger electrode size and uses a different resistance element material for higher power ratings and superior temperature characteristics.

The UCR series also minimizes resistance variations during mounting by adopting a post-mount configuration. (See Figure 5). The models are available in the ultra-compact size 0603 (UCR006 series), which offers an extended temperature range (-55ºC to 155ºC) ideal for the automotive market. The higher rated power of the LTR and UCR series makes it possible to use smaller resistors, replacing the conventional models of the MCR series, contributing to the final miniaturization of the product.

Low Resistance based on resistive metal

Metal band low ohmic resistors feature a completely different construction compared to thick film resistors, with resistive metal thicknesses ranging from tens of micrometers to a few millimeters.

This type of resistor is produced using various process technologies, such as etching and machining, and achieves target strength values and characteristics based on element formation.

As a result, metal strip resistors offer higher power ratings and more accurate temperature coefficient of resistance than their thick film counterparts. A relatively thick resistive metal is commonly used for the low resistance range in the 0,2 mΩ to 10 mΩ range.

In 4W and higher types, ROHM offers the PSR series, which is available from 0,2mΩ to 3,0mΩ. Proprietary welding technology is used to join resistive metal and copper electrodes, resulting in excellent heat dissipation and heat capacity. (See Figure 6) In addition, the series features large copper electrodes, so it is possible to increase the power rating to 5W while maintaining thermal dissipation characteristics. In addition, optimal resistive metal is selected for each resistance value to ensure excellent resistance temperature coefficient accuracy.

For power ratings less than 2 W, ROHM offers the PMR series, available from 1 mΩ to 10 mΩ. Although the PMR series is structurally different from the PSR series, both adopt metal alloy for the resistive element. In addition, the PMR series does not use trimming to adjust the resistance value, which prevents heat concentration (hot spots) on the resistive element during use. (See Figure 7).

The PMR series has been expanded to include the industry's smallest class of resistors, with further miniaturization anticipated. ROHM is also increasing its range of PMR series long lead resistors that offer increased junction reliability and heat dissipation.

future developments

In order to support low resistances of more than tens of mΩ in the region of +1W, the thickness of the resistive metal must be around 100um. However, since the resistive element itself comprises the main body, chip formation is difficult. And while it's possible to bond a tough material to the substrate to form the main body, ROHM hasn't expanded its lineup to include this type.

In this industry, many users have adopted conventional or thick film resistors, but in recent years the demand for metal strip resistors has increased in response to various requirements, such as higher detection accuracy, miniaturization of the board, and the reduction in the use of conventional components.

In response, ROHM is positioning its line of metal strip resistors to meet these anticipated needs, developing new products that are more compact and have greater heat dissipation.

As mentioned above, with expected increased demand for lower resistors in the automotive industry, ROHM will continue to expand its line of resistors, focusing on improving power rating and thermal dissipation while further reducing the size.