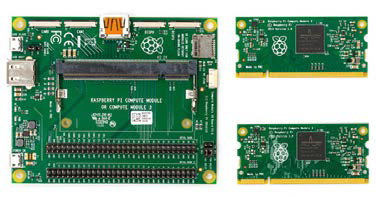

The success of Internet of Things (IoT) devices comes as no surprise. IoT engineering kits and the right technologies to design IoT prototypes are affordable and readily available for creative tech hobbyists. Therefore, there are no limits when it comes to exchanging ideas and possible business models based on these technologies.

In the industrial environment there has also been a rapid growth in demand for professional IoT applications. Common features include the ability to distribute intelligence by connecting various sensors and switches with decentralized control. The ability to make them intelligent is that these sensors and switches can collect and transmit data and are designed to be intelligently managed. The market for industrial IoT applications will continue to expand as more applications evolve, including (home) healthcare, infrastructure, utilities, home automation and smart homes, vehicles, mobility, and more. These professional IoT trends will undoubtedly involve the miniaturization, mobility, robustness, efficiency (degrees of effectiveness) and the connection of electronic devices.

Unlike hobbyist IoT applications, these security-relevant industrial IoT applications are subject to strict regulations, both for the engineers and the components used. This poses a great challenge for developers of industrial IoT applications. The use of certified, reliable, and long-term available electronic components is critical, and these are often used in safety and performance-critical applications. Professional support from component suppliers plays a very important role.

Requirements for powering professional IoT applications

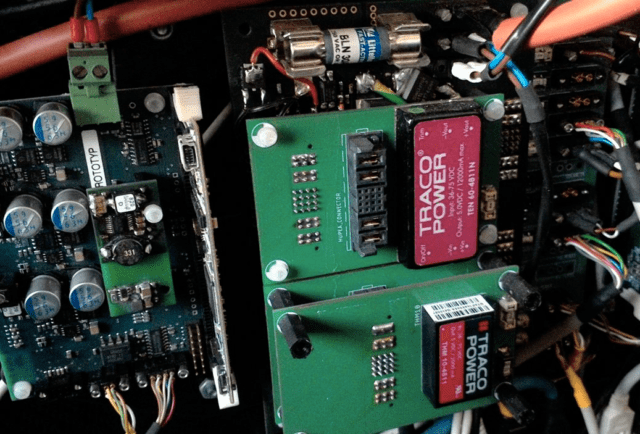

The critical modules in professional IoT devices are undoubtedly power converters and power supplies. Miniaturization, low power consumption, size, and high efficiency play an increasingly important role in these products. Semiconductors are probably the components that offer the highest level of innovation. As a second key technology, I would mention the energy transformation and isolation devices used in these products. Additionally, since these mostly battery-powered IoT systems spend most of their time in standby mode and only a small part is in active mode, integrated DC/DC converters must cover a wide charging range with high efficiency. Both size and efficiency matter, anything else?

To design, certify and market this type of IoT devices, not only the technological characteristics of the product matter. In order to certify and sell these professional IoT devices, they have to fully comply with increasingly stringent regulations due to globally harmonized standards and guidelines, presenting a great challenge for today's IoT electrical engineer. If IoT functionalities are required for mission-critical applications like medical technology, electronic components must be designed in a way that they can be used accordingly, meeting specific industry standards.

Take, for example, a battery-powered, physician-approved wireless control panel with internet access to patient records. Wirelessly connected to this control panel is another device that can come into contact with the patient (eg a blood pressure monitoring device). One of the key safety considerations when it comes to medical devices is that the patient is often electrically connected to the device. As a consequence, the power supply and DC/DC converter of this IoT application must comply with safety-critical regulation such as BF compliance and 2xMOPP standards within the third edition of IEC/EN 60601-1.

Another good example is the industrial applications of IoT in “smart” homes and buildings.

High efficiency and low no-load power consumption (ERP compliant), small footprint, high reliability, and affordable price are key elements for all these home and home IoT automation applications, as well as increasing compliance requirements. and standards, including IEC/EN 60335-1.

Careful planning is required with the entire supply chain

We know that the use of new technologies in sensitive and function-critical applications requires higher reliability, quality, lifespan and certifications and, last but not least, seamless traceability of key electronic components.

Manufacturers increasingly need to use tools that have been established and refined in the automotive industry over the years, such as failure mode analysis, corrective actions, 8D reporting, DFMEA, PFMEA, complete quality and continuous improvement.

Today, total quality has to find its way into the earliest phase of almost any project. To achieve this, a developer today has to do more than just provide an effective solution. Where once a mobile phone was a useful accompanying instrument, it leads us today to dispense more and more with the redundancy of other means. The cash, the camera, the address book or the subscriptions are all integrated into the mobile. Smartphones, therefore, have become crucial life companions. Today product design bears a much greater responsibility for the quality of its development than it did ten years ago. We all know that this trend is not only continuing, but will continue to develop rapidly. Furthermore, suppliers should regard the digital transformation of the supply channels of individual components as an extremely important development. By establishing, analyzing and processing relevant data, fast, reliable and cost-effective component availability can contribute to higher productivity at customer sites.