Data-logging instruments have a long history dating back to the 1800s, when Charles Babbage attached a mechanical instrument called a dynamometer to a train carriage to record more than a dozen parameters. Babbage described his prototype as a XNUMX-foot-long scroll of paper slowly unrolling on a long table. The model had about a dozen pens connected with a bridge that ran across the center of the table, each marking a separate curved ink mark. Since then technology has advanced to the point where we can record a significant number of sensors in a small portable instrument.

How Data Loggers Compare to Digital Multimeters and Oscilloscopes

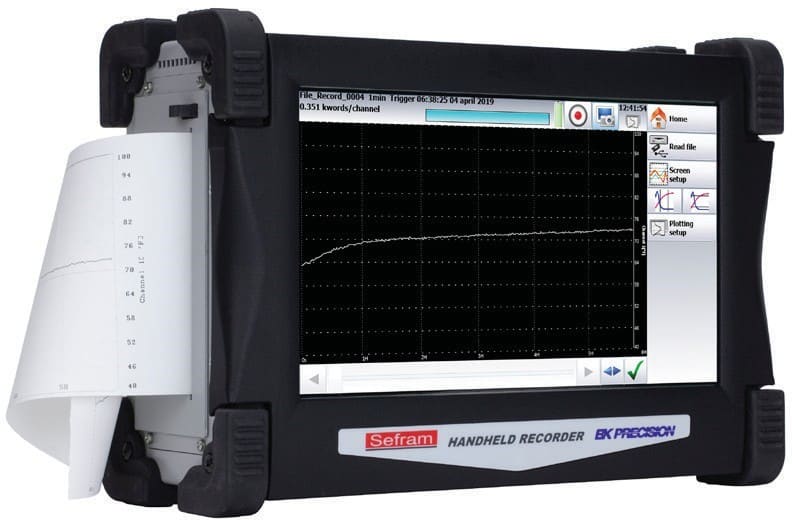

Older data loggers tended to be limited to recording only signals that had slowly changing values. This was because they had limited response times due to the electromechanical pencil and paper system used to archive the data. Today, these limitations do not exist, especially in the latest generation of cash registers. Today's data loggers feature fast sample rates, large internal memory, touch screens, and a wide variety of input capabilities. The recorders can replace various instruments and offer additional options such as thermal printing and analysis of communication buses.

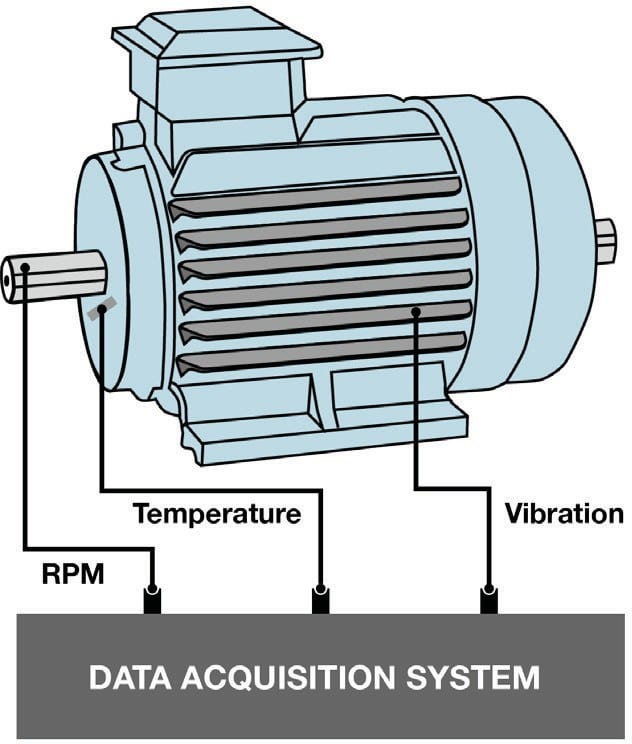

Digital multimeters (DMMs) are primarily used to measure voltage, resistance, and current. Data loggers, on the other hand, are capable of measuring the same parameters, but in addition they can also monitor temperature, humidity, vibration, strain, stress, and revolutions per minute (rpm) to name a few. Unlike typical DMMs, recorders excel at making measurements on multiple channels simultaneously. The data can be analyzed on your screen with built-in cursors to select specific details of the waveform, or it can also be transferred to a computer. Registers also perform more complex operations, such as writing custom equations to perform mathematical calculations between two or more channels.

Digital Storage Oscilloscopes (DSOs) have become widely used instruments for capturing and storing waveform data, and have evolved to include fast sample rate triggering capabilities. By comparison, data loggers offer more channels (up to 200 in some cases), higher vertical resolution, and more internal memory, allowing more signals to be recorded and compared over a longer period of time. When using a DSO, it is possible to miss the trigger event, but a data logger will capture it because it is continuously recording. All BK Precision data loggers feature a pre-trigger option to set the percentage of capture time before and/or after the trigger event, ensuring none of your valuable data is lost.

It is not unusual for data recorders to have the same type of triggering mechanisms available in oscilloscopes, including triggering based on the leading and trailing edges of the signal being recorded. In addition, it is relatively easy to provide the same type of analysis available on specialized instrumentation, such as power line quality monitors. Data loggers have the same XY displays found on oscilloscopes.

Applications where data loggers are used

Users who need to acquire data over long periods of time on multiple channels or from a variety of signals and sensors will benefit from the use of data loggers. These instruments have been designed to allow direct input and measurement of a wide variety of parameters such as voltage, current, frequency, temperature, strain gauges, and logic signals with voltage inputs ranging from millivolts to kilovolts. This allows a single instrument to simultaneously measure small voltage signals from different sensors up to high voltage signals in a power system, while reducing the challenge of setting up multiple instruments.

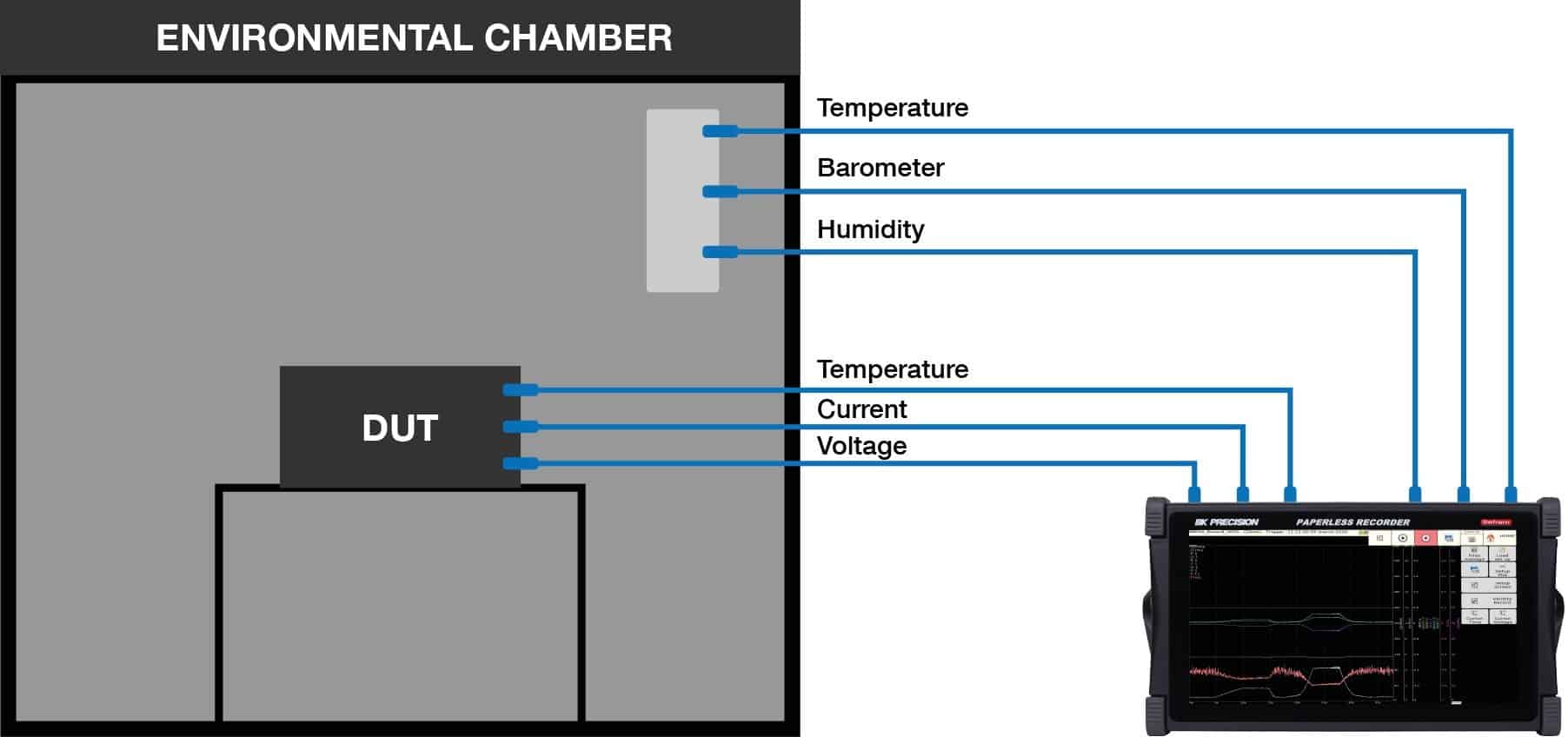

A common application for data loggers is environmental testing where various sensors are required to monitor parameters such as temperature, humidity, wind speed and direction, as well as barometric pressure among others. These tests can also be performed in an environmental chamber to verify how the device under test responds to changes in environmental parameters while monitoring its voltage, current, and other parameters under observation.

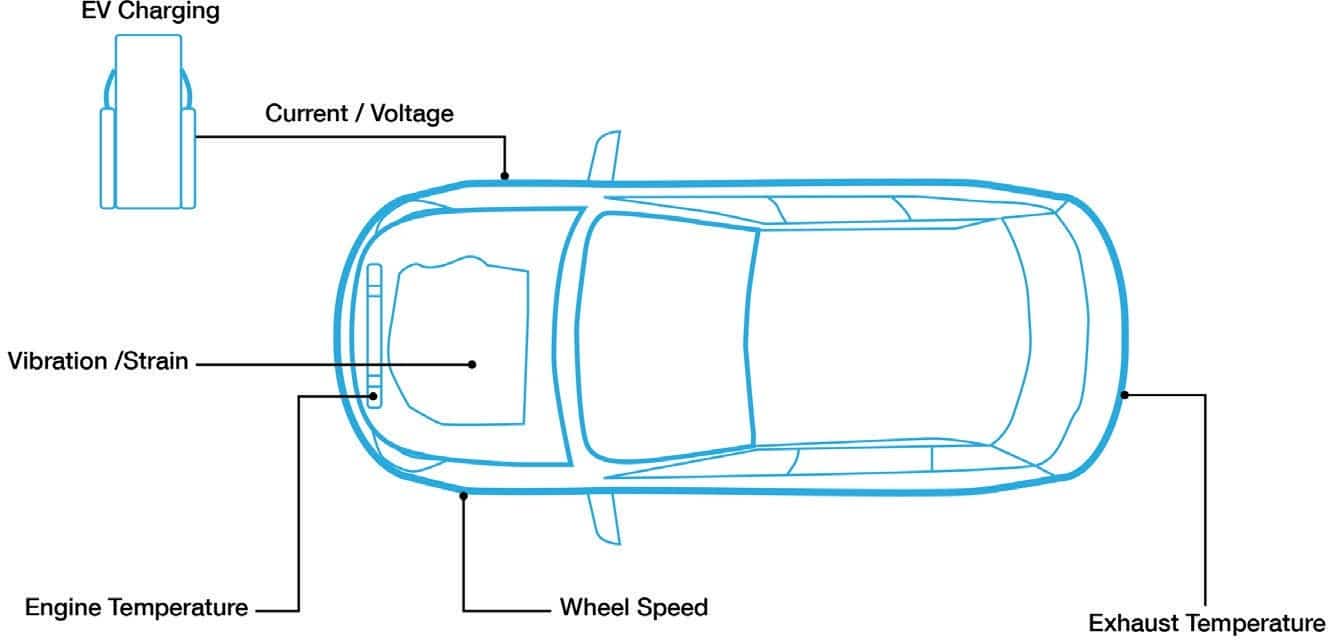

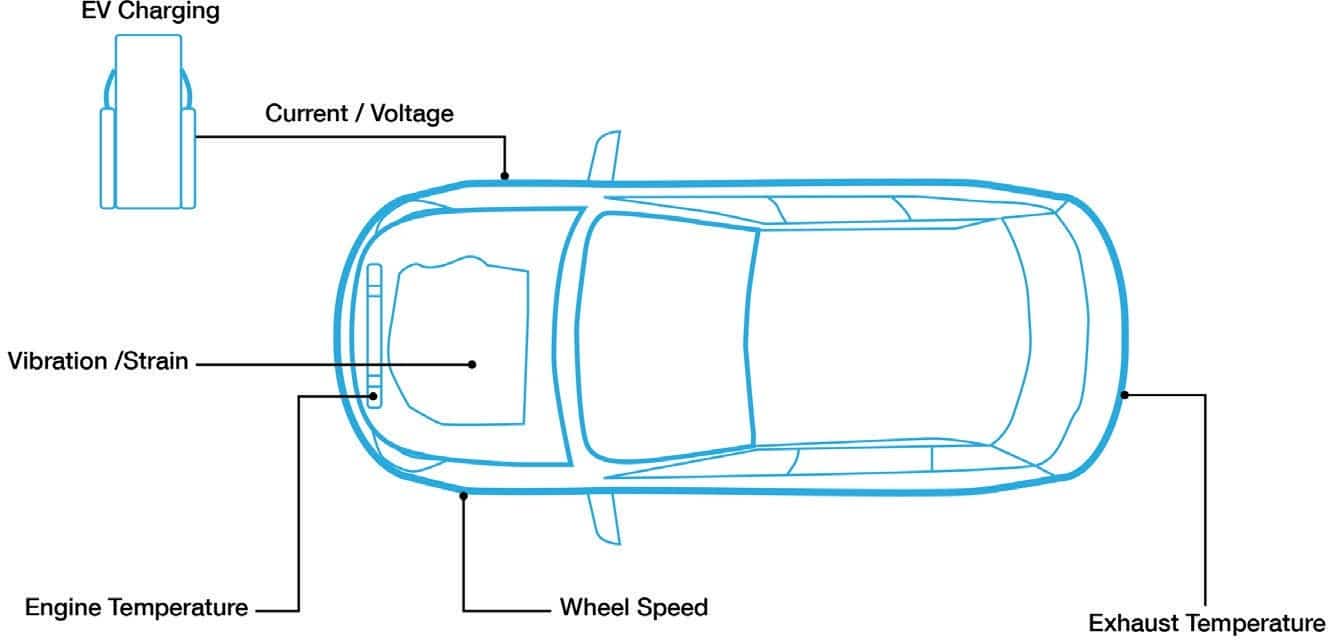

Cash registers are widely used in the automotive industry. Vehicle engines contain numerous sensors, electronic controls, and systems that the instrument can control simultaneously. Key measurements include voltage and current, force, pressure, revolutions per minute (rpm), speed, and temperature. Many registers offer the added ability to monitor and analyze traffic with CAN or LIN buses, which are widely used interfaces in this industry.

Data loggers are capable of monitoring systems in industrial settings. Portable cash registers help in preventive maintenance measures which in turn help to maximize productivity. They can be used to monitor voltage, current, temperature, strain, pressure, and vibration signals from industrial equipment, to detect abnormalities, and to record data that will allow for maintenance scheduling.

Important Specifications and Features for Users

When considering data loggers, the high-level specifications are:

- Number of input channels

- Types of measurements (for example voltage, current, frequency)

- Minimum and/or maximum input voltage

- Sampling rate

- memory size

- Operating modes

The cited specifications help determine which instrument meets individual needs. The number of channels is a factor to consider and how it affects its portability. As the number of channels increases, the weight of the unit also increases.

Measurement types and voltage input ranges are fixed numbers that need to be adhered to, but sample rate and memory size require more consideration. Although a faster sample rate might be desirable, it will reduce the maximum recording time, due to file size when recording many measurements in a short time. For this reason, in order to select a recorder it is important to understand the nature of the signals to be captured. Many data acquisition systems have multiple modes of operation: one mode is recording over long periods of time with a low sample rate, and another mode is recording at a higher sample rate for a shorter period of time to capture intermittent events. .

In addition, some recorders provide the ability to synchronize to an external time base, such as IRIG (Inter-Range Instrumentation Group) time codes or GPS signals.

How BK Precision Meets Customer Needs

BK Precision offers a complete line of data acquisition recorders with touch screens, batteries built-in and multiple channels.

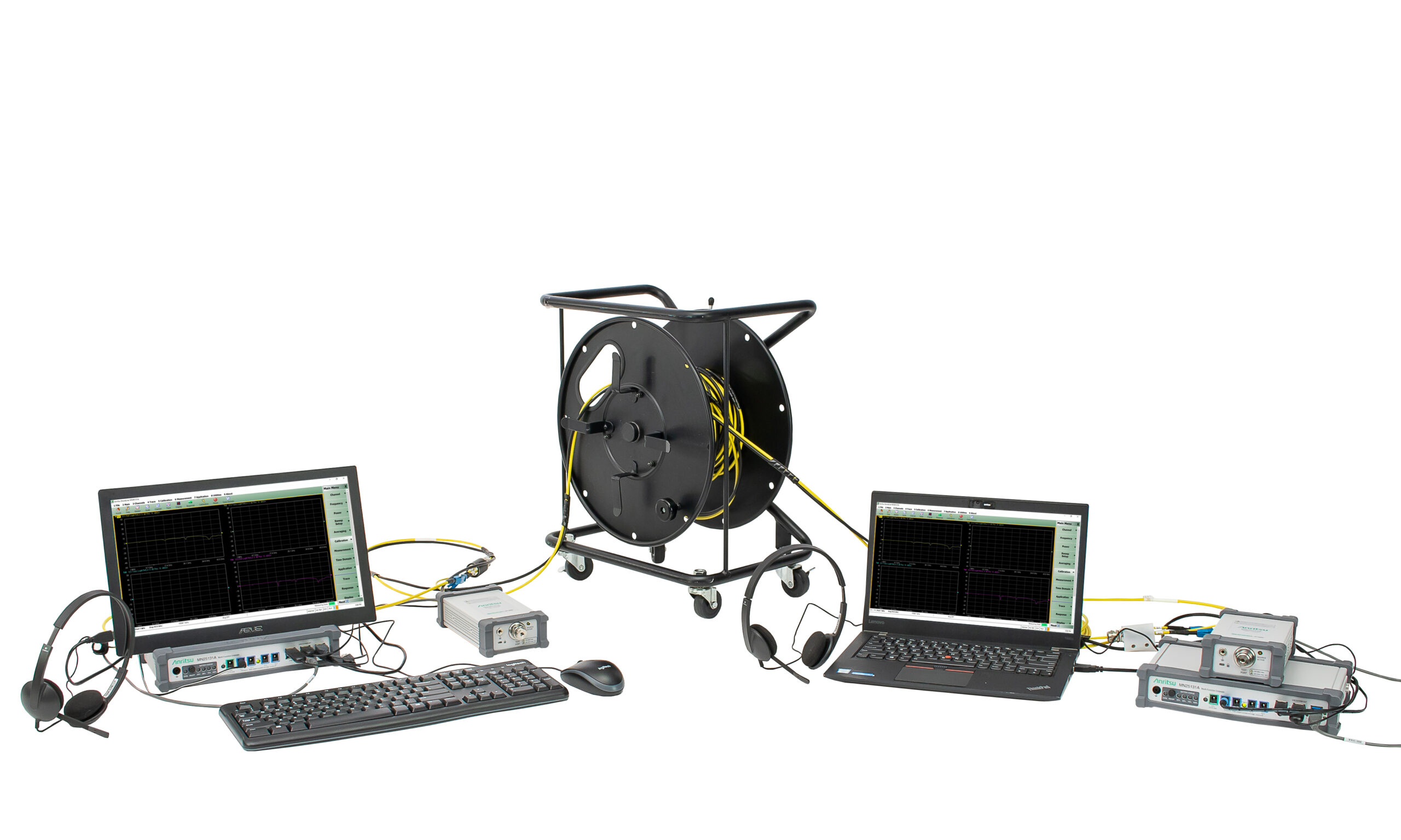

The DAS220-BAT and DAS240-BAT data loggers are lightweight and portable, with built-in batteries that provide up to 15 hours of continuous recording on 10 or up to 200 channels with 1 ms sampling intervals, 16-bit vertical resolution, and input voltage. 100 VDC maximum input. The long battery life makes them of great benefit in process control applications, where power sources are not available. The DAS30/50/60 Series offers 2,4 and 6 channels, built-in battery that allows recording up to 9.5 hours of continuous recording time and optional thermal printer. This series offers 1 µs sampling intervals in memory mode, built-in SSD up to 64 GB, and 500V maximum input. The power analysis application included with this series allows recording and analysis of single-phase or three-phase electrical networks.

The newest addition to the data logger family, the DAS1700 model, is a configurable data acquisition system. The instrument has 4 types of measurement cards that can be installed in any combination of up to 3 cards in the base unit of measurement.

the register, or up to 6 with an optional extension. These boards include a 500-channel universal input with maximum voltage up to 6V, a high-voltage board, a 6-channel strain gauge board, and a 12-channel multiplex board.

The DAS1700 is capable of transmitting measurement data directly to an internal solid-state drive with a 1 µs sampling interval (up to 36 channels) and continuous recording for extended periods of time, with recording length only limited to the size of the SSD. The instrument is also capable of recording two files with different sampling simultaneously in one recording. When recording starts, the low-speed file captures data at a lower sample rate over a long period of time. When a trigger event occurs, the recorder starts recording to the high-speed file that captures data at high sampling rate for a shorter period of time. This ensures that not only the event is captured, but also the states before and after it is captured, while maximizing memory space.

The DAS1700 recorder expands the measurement range to a maximum input of ±1,000 VDC or 1000 VAC. It also includes the power analysis tool, present in the DAS30/50/60 Series, but up to 4 systems. In addition, it has a function editor that allows presenting the results of those multi-channel operations in a virtual channel. Factory CAN/LIN and GPS/IRIG timing options further expand your capability. This data acquisition system is suitable for measuring signals ranging from small sensors to large electrical systems and is used in aerospace, industrial, automotive and power generation applications.

Conclusion

Data loggers have a long history and continue to advance to keep pace with today's applications. It is clear that these instruments are essential tools in many industries and BK Precision brings complete data logging solutions to market for customers in these industries. For more information on BK Precision's data loggers, please visit their data loggers page linked here.