National Instruments has spent 36 years pioneering technological advances making life easier for engineers. Here, Dr. Truchard and other NI leaders reflect on creating the company's vision.

Since the company's founding in 1976, National Instruments' long-term vision has been to make engineers and scientists more productive using commercially available technology. We look at trends across industries so that we can develop products that meet technological demands as soon as they are released. Because of the diversity of NI customers, we're in a unique position to stay on top of trends in measurement, sensors, networking, test, and more. NI has used the latest trends in technology to manage business development since the company was founded.

The early days: The marriage of computers and instrumentation

“NI has been innovating in instrumentation of all kinds because we recognized the potential of personal computers early on,” said Jeff Kodosky, NI co-founder and business and technology partner. “We knew that PCs belonged to the measurement and automation domain. From the beginning, we recognized what Moore's law was making possible. Higher computing power at lower cost was the reason to build the system on top of the PC to get to market faster.”

As the company grew, NI began producing a wide range of GPIB products and invested heavily in research and development. “We started the company with GPIB interfaces that harnessed the power of the PC by connecting it to an instrument,” said John Graff, vice president of sales at National Instruments. “Because we used the union of the computer and the instrumentation, we had the advantage that it helped us to recognize the great potential of bringing these two technologies together. So we started down the path of developing products that would meet a broader range of engineering needs.”

A Virtual View: The Birth of LabVIEW

In 1984, the company decided to take advantage of the new graphical interfaces on the Macintosh. Jeff began a research initiative, which led to the creation of NI LabVIEW system design software in 1986. “We decided to create a tool that was going to be as productive for engineers as the spreadsheet was for accountants,” Kodosky said. "I can't believe we had the audacity to have that vision... I still pinch myself to make sure I'm not dreaming that everything is resolved."

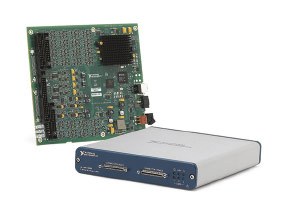

NI has pioneered the virtual instrumentation movement from the very beginning. With LabVIEW and the first I/O cards, NI provides a concrete vision of what virtual instrumentation could be and how it could change test and measurement in positive ways.

Extending the NI platform with PXI and NI CompactRIO

In the years that followed, NI engineers continued to push the boundaries of virtual instrumentation. “We had done data acquisition and plug-in instrumentation, but PXI really started the transition to software-defined modular instrumentation, which has been a big growth area for us,” Starkloff said. “The combination of LabVIEW and PXI helps engineers solve virtually any engineering challenge.”

Today, we are the leading provider of PXI with more than 1,500 products from more than 70 manufacturers. Engineers around the world have turned to PXI to achieve faster test run times, improved development productivity, better performance, and increased scalability, which, true to NI's vision, dramatically reduces system complexity and costs. total costs.

In the late 1990s, customers began using LabVIEW in industrial automation applications. With LabVIEW and more advanced NI DAQ cards, engineers were then able to replace expensive, fixed-function, manufacturer-defined instruments with a custom PC-based system that more flexibly acquires, analyzes, and presents data at lower cost.

In 2004, we introduced NI CompactRIO, a reconfigurable embedded acquisition and control system. CompactRIO took us down the path of FPGAs as a programmable element of a measurement and automation system. This year, we introduced the first controller designed in software with the NI cRIO-9068.

NI Today: Pursuing the Toughest Technical Challenges

Although NI is now a billion dollar company with offices in 45 countries around the world, our long-term vision and mission has not changed. We are constantly announcing products to meet new market demands. For example, to help engineers and scientists keep up with the mobile explosion in recent years, we created the NI Data Dashboard for LabVIEW app for tablets to bring measurement and control anywhere, anytime. We're always looking for the next tough challenge, and we're willing to invest in the future to solve it.

“Our customers can expect that when they are trying to figure out new technologies such as the cloud or FPGAs, we will give them the tools and solutions to help them succeed,” Santori said. “We help manage the risk of trying new technologies. Because we are committed to client success, we are not going to recommend something that we don't think will generate a significant return on investment.”

Beyond a Billion: What's Next for NI?

NI has evolved over time, but the vision remains the same. “We adopted the term 'Graphical System Design' because it encompasses not only our vision for test and measurement but also our vision for embedded design,” Kodosky said. “There is a lot to do to complete that vision, so over the next few years we will be updating our product offerings for all the things we have laid the foundation for.”

NI customers from all industries and application areas tell us that their primary challenge is the increasing complexity of taking devices from design to test. At the same time, the pace of innovation continues to increase, so they have less time to test these complex devices. Our customers need a more seamless migration path from design to test to rapid prototyping, research and development, and manufacturing. Our approach has been to create a common platform for everything from prototype to embedded deployment. We believe that a common platform is the best way to face the increasing complexity and costs and to solve the great challenges of engineering.

Follow the evolution of NI in ni.com.