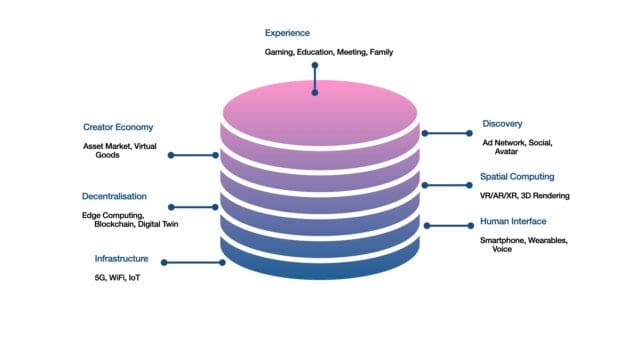

Figure 1: The metaverse is based on multiple layers and will make its way into many areas of our daily lives.

El metaverse is poised to become the “next big thing.” However, high-performance hardware is necessary for virtual worlds to become a reality. This also applies to pluggable connectors for cable communication and data exchange.

The term 'metaverse' is made up of the Greek word 'meta', meaning 'after' or 'beyond', and 'verse', short for universe, a type of parallel universe in which the internet comes very close to the reality in the form of a 5D virtual reality space.

The metaverse was created in the early 80s, but it has only now become a reality. Although, for the moment, the incursion of Facebook in the metaverse has not been very successful, many other companies have entered the development field, such as BMW, Caterpillar and DHL, to cite a few examples. Only for the gaming, entertainment, social media and augmented reality and virtual reality (AR & VR) hardware segments, Bloomberg intelligence It rates revenue potential at $783.000 billion by 2024. But the industry is also discovering the metaverse, increasingly bringing together the digital and physical worlds to achieve the promised efficiency gains. After all, in addition to the virtual worlds in which people will meet friends in the future, there are numerous application scenarios in the industry, such as remote support services for the repair of complex machinery or the creation of a digital twin in centers of production, including the supply chain, infrastructure and value creation processes.

Potential benefits of a metaverse for businesses

For both companies and entire sectors, the metaverse could add economic value, especially where interaction and exchange play a crucial role: along the supply chain, in purchasing and after-sales or in the coordination of suppliers.

Additionally, it will allow companies to save valuable time that was previously spent traveling. This will have a huge impact on customer service and sales. It is possible to optimize collaboration between co-workers and with business partners and reduce the need for office space. Interactive simulations can accelerate training and education and achieve better results by allowing employees to operate equipment as they would in the real world or practice sales techniques for key accounts. It is no longer necessary to exchange information about highly complex machinery and equipment in the form of abstract technical sheets; Instead, the machines can be viewed from any angle in a matter of seconds. This immediately creates a precise idea of its size, mode of operation or integration into a production line.

Real building blocks for virtual worlds

Despite being virtual, the metaverse is based on hardware. To enter these worlds as an avatar and interact with other people, such as when a technical service professional from a machinery manufacturer repairs equipment at the customer's side, users must have computer hardware and devices, including graphics cards. , virtual reality headsets, high-speed internet connections and high-end computers. However, most of the components available are not powerful enough to cope with the immense amounts of data required.

Nor do current internet and data centers have the speed or capacity for truly immersive, permanent computing that people can access in real time. This would require a thousand-fold increase in processing power compared to the latest generation of technologies, according to Raja koduri, Senior Vice President and General Manager of the Graphics and Accelerated Computer Systems Division of Intel. And this will take time: a Moore's Law standard curve will only give us about eight or ten times growth in the next five years and Koduri said this in an interview at the end of 2021.

Additionally, to reduce communications latency to almost zero, data centers must be located very close to users. To benefit from a decentralized, secure and intelligent network, edge and cloud computing devices and servers will be connected (edge y cloud computing) in multiple locations across the cloud itself. And cloud service providers will likely unite dozens of distributed data centers in a single city to provide the fast response times and low latency demanded by new edge computing services.

As metaverse applications deliver high-speed data to the end user, there is a growing need for server operators to build open source-based infrastructure to meet metaverse performance requirements. This is because open source technologies and projects help organizations shorten the time to market for new applications, enabling faster payback on infrastructure investments. At the same time, this lays the foundation for a collaborative industrial model that supports improvements in the interoperability, scalability and programmability required for metaverse applications.

Connectors for the transmission of large amounts of data

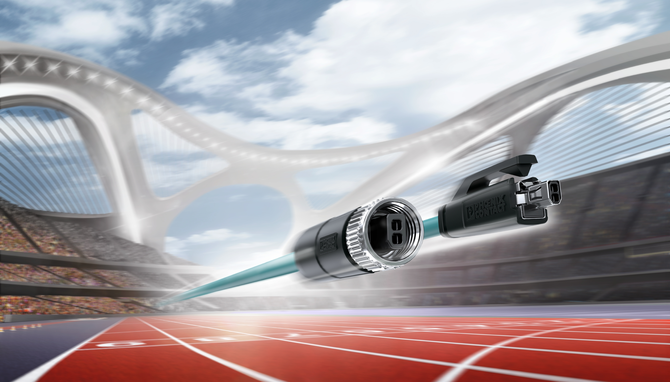

If edge infrastructure is to be able to deliver metaverse applications, the need for hardware acceleration will also increase. To bring Ethernet to the edge, for example, edge server operators can turn to a pair's Ethernet socket (single-pair – PES) newly developed from amphenol. Your connectivity from the edge to the cloud (edge-to-cloud) with a power of 50 W over the data line makes it easy to connect numerous devices (Fig 2).

Figure 2: The shot single-pair Amphenol Standard Ethernet (SPE) with edge-to-cloud connectivity and 50W power over the data line.

Big data metaverse applications using artificial intelligence (IA) and transmit audio, video, high-resolution images and large files between multiple devices demand a significant increase in bandwidth and power. In turn, a greater amount of data requires faster and more reliable communication. For example, the socket DDR5 SO-DIMM Amphenol responds to this demand by supporting data speeds of up to 6,4 Gbit/s with a simple output pin assignment (single-ended). In comparison, DDR4 DIMM models are only half as fast (3,2 Gbit/s). It also has half the density of conventional alternatives. With a lower memory voltage of 1,1V, it consumes up to 20 percent less power and offers better thermal management. This also helps reduce the consumption of edge data centers (Fig 3).

Figure 3: Amphenol DDR5 SO-DIMM socket supports data rates of up to 6,4 Gbit/s with one pin assignment single-ended.

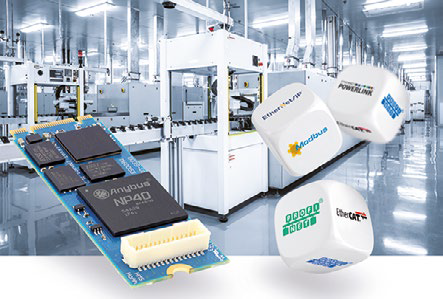

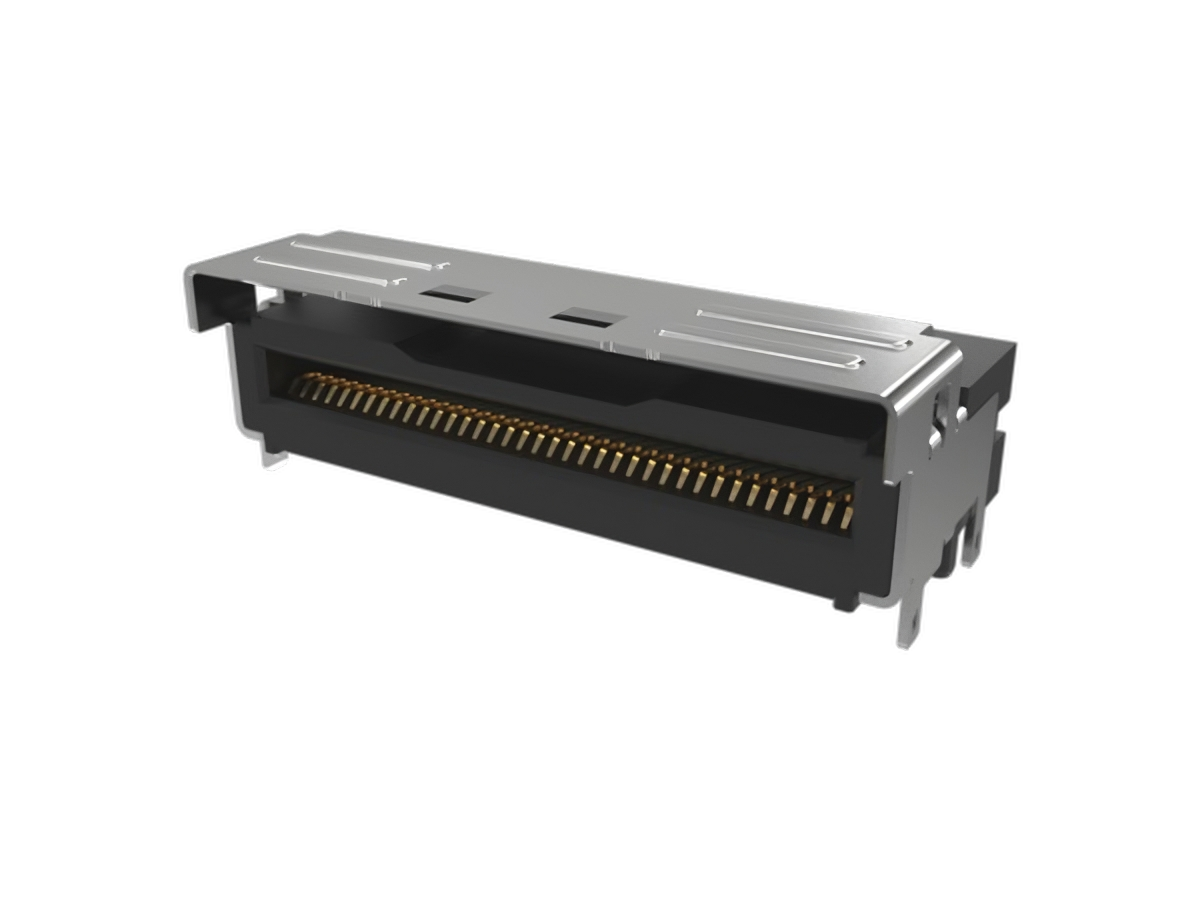

As the metaverse becomes more prevalent in the industry, it will be increasingly important that components have a long lifespan – some plug-in connectors are not replaced for years. At the same time, they must be efficient and as immune as possible to electromagnetic interference (EMI). The new generation of socket connectors MCIO (Mini Cool Edge IO) Amphenol's high-density foam meets these needs. It can transmit signals at a speed of up to 64 Gbit/s at a distance of 1 m and meets the new requirements of PCIe Gen6. Additionally, MCIO socket connectors are durable, highly scalable, and affordable components, making them ideal for edge servers (Fig 4).

Figure 4: The Mini Cool Edge IO (MCIO) socket connector is durable and can transmit signals at up to 64 Gbit/s at a distance of 1 m and meets the new PCIe Gen6 requirements.

Although it will still be some time before the metaverse is a reality, it is already safe to assume that it will be the next big working platform. Thus, Rutronik accompanies its customers and suppliers as a partner on this digital journey and supplies solutions that pave the way to the new virtual universe.

From the RUTRONIKER editorial team we want to show our special thanks to Mariarita Novelli for her help in preparing the technical article and the visual material that accompanies it.