Isabelle Sourmey and Jean-François Savin – Application engineers at Saft.

Yes! The batteries you ordered have just arrived and will give you an 8-year warranty on your IoT application!

If you are a developer of IoT solutions, you will want to check the quality of the primary batteries you receive. To do this, proceed with your tests:

- Initially, you will verify that the package is undamaged, and that the batteries inside the box are packaged correctly (for example, without short circuits).

- He then randomly selects battery packs, and performs a visual inspection to confirm that there are no signs of leaks or dents. So far, all good.

- Then it goes to the important phase: check the battery capacity. Sure, you've done testing during the prototyping phase, and the battery manufacturer has told you the expected life of the batteries in your application, but you still want to make sure the final product lives up to their expectations! expectations! One way to do this is to continuously discharge at high currents and get results quickly. You need to quickly launch your product to the market and you are not 8 years old!

But oh, disappointment, disappointment! Not only are the performances wildly different from what is stated in the battery data sheet, but the battery capacity is well below the 8 year rating for your application!

Before you pick up the phone and file a complaint with the after-sales service, you should read this article, as this type of test does not represent the behavior of the battery in the field. Therefore, here we tell you how to go ahead with your initial inspection, and thus see the real picture.

Why an accelerated discharge is NOT the way to go to check your battery

In summary:

- Typically, IoT batteries are not designed for continuous discharge at high currents: therefore the results obtained are not relevant to your application

- A high current discharge does not give the same capacity as a nominal current discharge

- Cell orientation can also play a role in cell performance, under continuous high-current discharge.

- A high current discharge can cause an electrochemical blocking phenomenon of the cathode.

- A continuous download does not represent the behavior of the cells in the application. It is normal to have different current pulses.

- Watch out! The behavior of a new stack is not the same as that of an old stack.

1- Batteries have different technologies and construction, designed for an optimal scope of use

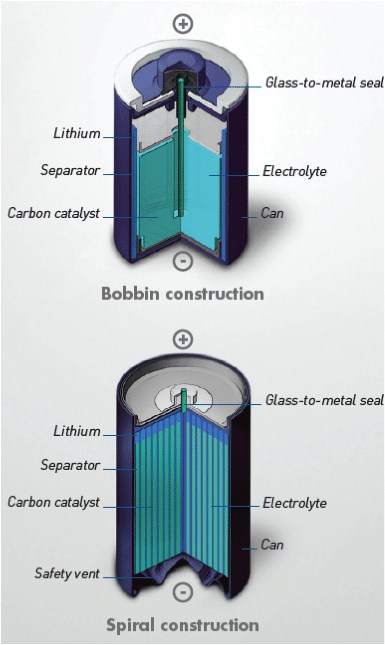

First of all, you need to remember that battery cells are designed for a specific use. Depending on their construction (coil or spiral) and their electrochemistry (here we are dealing more specifically with lithium primary systems), they will behave differently. For lithium thionyl chloride systems, coil cells are optimized for low discharge currents, and to be used for up to 20 years, while spiral cells are designed for higher discharge currents, and to be used for approximately up to 10 years. In contrast, lithium manganese dioxide systems only come in a spiral design and are therefore designed for high discharge currents.

2- Most IoT systems today are optimized for their energy needs.

Low power electronics, deep sleep mode, and improved component leakage currents are widely adopted trends in the IoT world. Coil cells lithium thionyl chloride (Li-SOCl2), have been extensively designed to meet the needs of these low power applications. Therefore, when using a coil cell, high discharge current will not account for battery behavior at all, especially for a low power application.

Let's look at the datasheet to understand the principle.

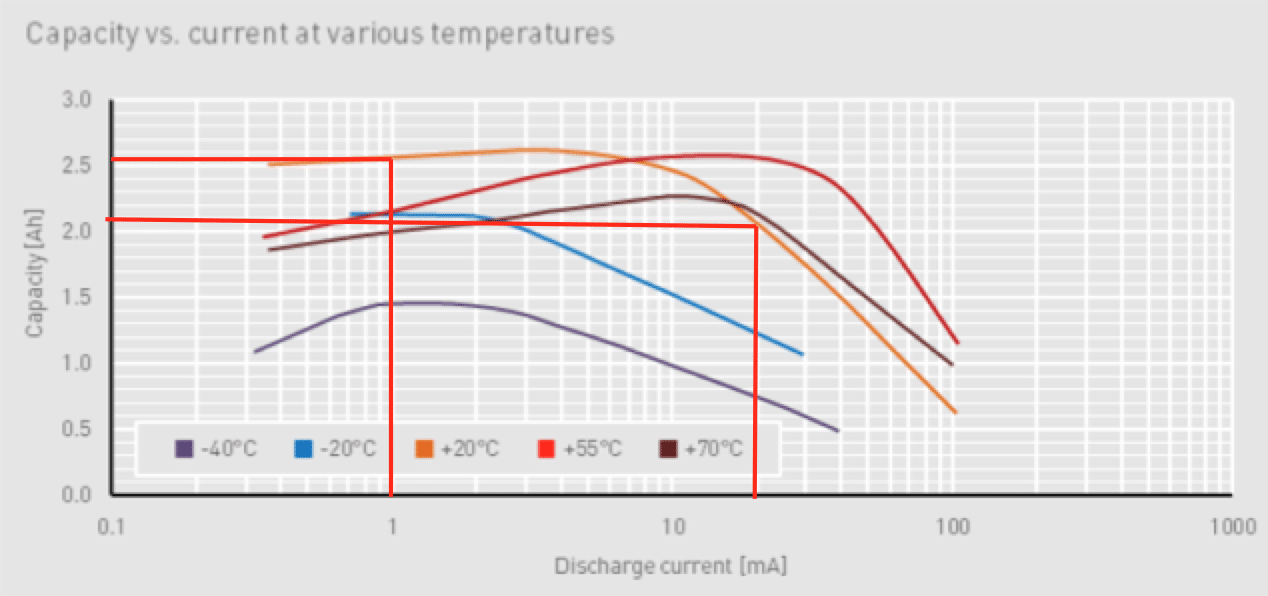

The impact of a high discharge current on the available capacity is shown in the "Capacity vs. Current, at Various Temperatures" graph.

In this example of a Li-SOCl battery2 With LS 14500 coil, we can clearly see that, at 20°C, the cell gives the same capacity with 20mA or more, as with a continuous current drain of 1mA.

With a discharge current of 1 mA, the maximum capacity would be 2.6 Ah at 20 °C, but with a higher discharge current draw, say 20 mA, the restored capacity drops to 2.1 Ah. So by increasing the discharge current by 20, the total battery capacity is reduced by almost 20%.

While this goes for any battery, it is even more true for Li-SOCl coil cells.2 (Saft LS range), optimized for low discharge currents, and long service life. Generally for discharge currents in the range of a few mA. Therefore, high current draw, above 10 mA, will reduce cell efficiency (with possible carbon saturation phenomenon), and cell capacity will not approach nominal capacity. The results that you would obtain by applying these capacity tests could be distributed in a wide spectrum of values, showing the most “typical” ones in the data sheet. So it doesn't make much sense to apply a high current DC to check the capacity of a cell.

3- The orientation of the battery in rapid discharge can have a great influence on the results.

Some of our customers have, on occasion, been puzzled by the download curves with fast download speeds, because the cell was not upright during testing... In fact, Voltage stability after medium discharge can also be affected by cell orientation under rapid continuous discharge conditions. This phenomenon is calledgrass effect«. When the contact between the carbon pores and the electrolyte droplets is temporarily lost, the voltage drops rapidly. When it recovers the next moment (the electrolyte returns to the inside of the pores), the voltage increases. It is also the result of the lack of electrolytes within the pores of the carbon support, at the end of a continuous discharge at high speed.

Once again, these phenomena are only noticeable for coil cells with rapid discharge, when they are not used in an upright position. A low discharge average, and a long recovery time between high pulses will allow the proper functioning of the battery, whatever its orientation. For this reason, tests with fast discharges can give rise to unacceptable results, even if they are not representative or relevant for their application in field life conditions.

Cell orientation effects with a Li-SOCl coil cell2, like Saft's LS series cell, is a phenomenon only noticeable under continuous discharge combined with high discharge rate (ie accelerated discharge). It will never manifest or reduce battery life, if used in actual application.

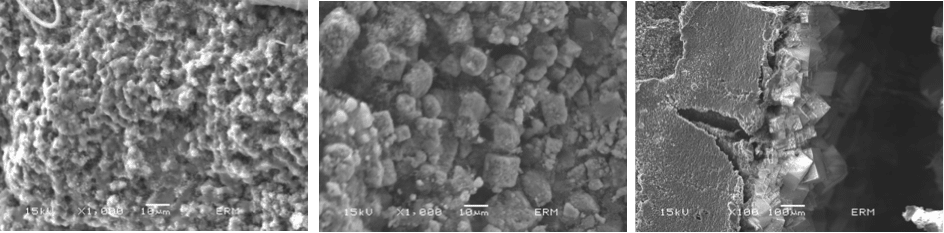

4- Discharging a coil type cell with high currents can cause a cathode blocking phenomenon

Some customers may also experience failure when discharging a Li-SOCl coil cell.2, if the discharge rate is too high. In fact, there is a phenomenon called «cathode blocking«, or phenomenon of «cathode limitation«. During the electrochemical reaction that results in the creation of a flow of electrons, the products of the electrochemical reaction (LiCl crystals) are stored in the mass of carbon. These crystals must go through pores that have to be opened to let them through: if the current drain is too high, it creates a massive flow of these discharge products, which reach the surface of the carbon mass. If the discharge is continuous, the surface of the carbon mass can quickly become saturated. And when that happens, the chemical reaction simply stops, even with some active materials left. Which means that the available capacity cannot be fully restored.

The images below illustrate this phenomenon by showing the surface of the carbon mass of a Li-SOCl coil cell.2, at different continuous discharge currents: we can observe that the LiCl crystals are larger when the discharge increases, giving rise to a superficial saturation of the carbon mass.

Discharge rate 30 mA Discharge rate 100 mA Discharge rate 200 mA

And that's not all! Getting good results with consistently high download rates doesn't even guarantee that your cell delivers the capabilities you expect for your IoT application.

Good results in fast downloading do not guarantee good results in the application, particularly for IoT applications, nor for applications with pulse currents, in general.

You may be tempted to test lithium primary batteries with high continuous currents during the control inspection, to ensure they maintain pulse current afterwards. The question is: batteries can withstand pulsing requests very well, even after time in the field, but may give low or poor capacity under continuous high current discharge. Conversely, you might end up getting good results if you discharge that fast - some battery manufacturers optimize their chemistry for exactly these purposes. These practices can lead to confusion for customers during testing.

A battery that powers an IoT application is expected to have the same performance throughout its lifetime. Therefore, looking at the voltage response capability of a new cell does not mean that over time the battery will achieve the same voltage response at high pulse currents. In fact, the performance of the new cells, especially with the voltage reading, is not a reflection of the performance of the old cells. Furthermore, the behavior of cells with high DC current consumption differs greatly from the response of a cell to consumption profiles for IoT devices, where they go into sleep mode most of the time, and then wake up for transmit data for a few seconds, thus generating a burst of current.

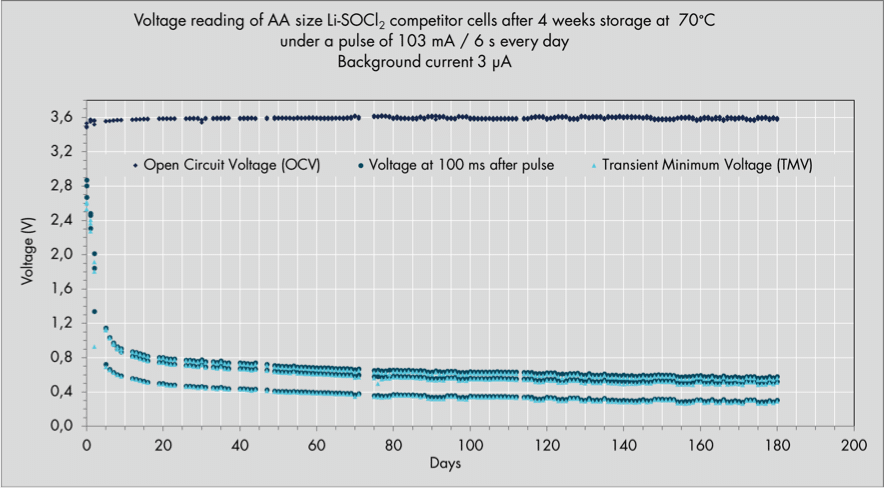

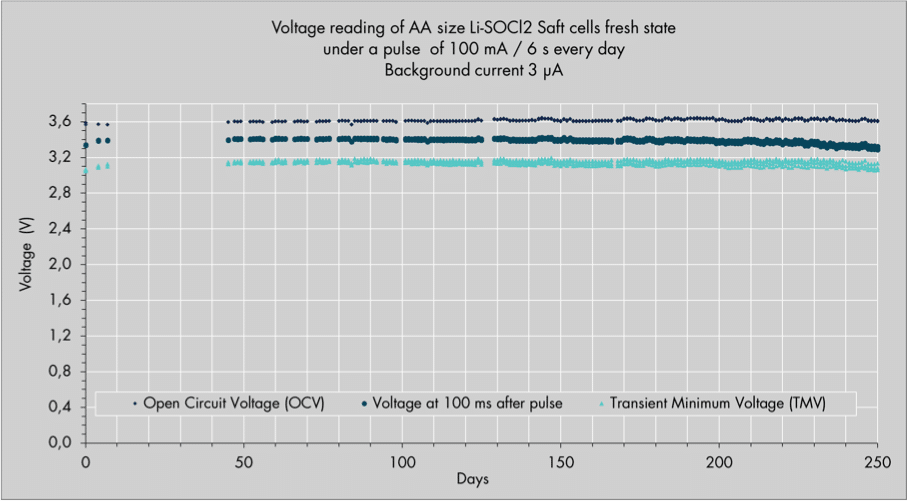

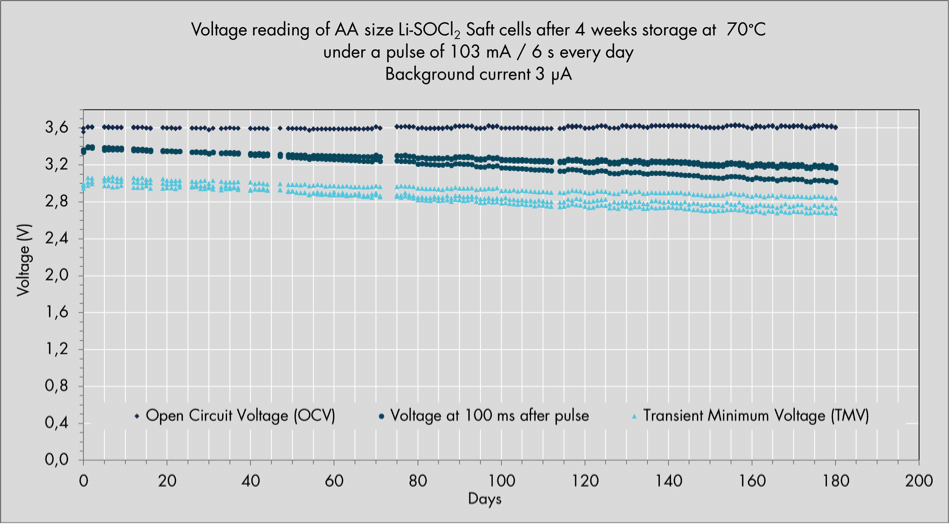

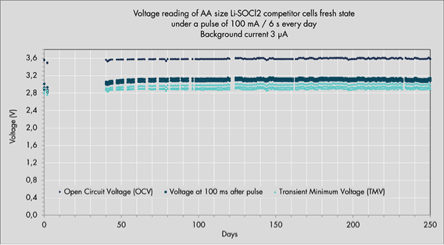

The results that you can see in the graphs below come from more than a year of testing. Saft cell voltage readings after a month's storage period at 70°C are above 2,4V, while competitors show voltage readings below 1V, not consistent with a response of expected voltage to power an IoT solution for several years.

So what can we learn from these curves?

- The pulse capacity shown in the datasheet does not represent the pulse capacity needed for an IoT application, as it only shows the capacity of a new cell, for a short period of time, and at 20°C

- A lithium thionyl chloride cell does not react the same way to a high pulse request when fresh, or aged.

- Therefore, requesting the cell during the control inspection with high continuous currents or high pulse currents for a few days, is not representative of its behavior after a few months in the field. At first glance, Saft's cells don't appear to be as good as their newer competitors, but over time power readings improve a lot.

- Conclusion: using a Li-SOCl cell!2 of AA size coil for a long term 100 mA pulse will not be possible without a capacitor!

So how should I inspect the batteries I buy?

Instead of running tests that are only 50% relevant, our best advice would be to audit your battery manufacturer to verify their quality control processes. Then you can ensure that the batteries are checked frequently, and that the quality is consistent.

You can also request a certificate of conformity: battery certification services test batteries for safety and quality, and ensure compliance with relevant standards and regulations.

And if you prefer to test it yourself, you can perform an OCV (Open Circuit Voltage) test, which involves connecting a voltmeter to the positive and negative terminals and measuring the voltage at the no-load terminal, or with a CCV (Open Circuit Voltage) test. closed), which consists of closing the circuit using a resistor (56 Ohm for an LS 14500 for example), and measuring the charge voltage after a short delay (2 s). A minimum voltage criterion can be established in the cell registered in 2 seconds, to classify the faulty cells in a very efficient way. This is much faster and more relevant than a download test!

If you would like more information on incoming inspection, please feel free to email us at contact@saftbatteries.com We will be happy to guide you.