Mark Patrick, Mouser Electronics

In recent years, countless predictions have been made about the huge impact that artificial intelligence (AI) and machine learning (ML) will have on our lives. All this comes at a price: it is predicted that by XNUMX this market will grow to an exorbitant amount of five hundred and fifty four zero million US dollars.

The industrial and manufacturing field is no exception: AI and ML are essential elements in the digital transformation of these environments. It is true that the presence of computers in factories is not something new: there are programmable logic controllers (PLC) everywhere, with very established protocols, such as SCADA. However, thanks to the Internet of Things (IoT), there are sensors on the manufacturing line that are producing an increasing amount of data. AI and AA use this information to encourage improvements and increase efficiencies in leading the way for industry forty.

Either way, let's put all the verbiage aside and focus on the practical. How can engineers use AI and ML to achieve real and measurable benefits? Is the technology sufficiently developed to justify its implementation in the factories or is it too soon?

To get started, let's get one thing straight: ML is not exactly the same as AI. Definitions vary, but everyone agrees that AI is, generically, a series of strategies to make computers think. On the other hand, ML can be defined more specifically as the sacrifices aimed at allowing computers to automatically learn and thrive from their work with data, rather than a human designing each and every aspect of it. of a program or a solution. In ML, we design algorithms and then our system learns by making predictions and checking their accuracy.

In industry, AA is used in very different fields: from precautionary maintenance to optimize the efficiency of processes, to simple, more essential tasks, such as managing the time to order spare parts or consumables. For example, a machine tool can have different temperature and vibration sensors. An AC system can learn exactly when that data indicates that a part is worn or out of adjustment, and predict that a failure is likely to occur shortly. This can be achieved by adding sensors to existing equipment or by using new machine tools that integrate the appropriate sensors.

Where is AA used today?

Let's take a look at where ML is being used for industrial automation today and look at some of these applications in more depth.

Some of the most common applications are:

Artificial vision: One application is quality control and inspection. The AA can learn to recognize drawbacks. For example, something as easy as missing an object on a conveyor belt.

In decision making: Data can be used to take the best possible action automatically and in real time, which improves efficiency and decreases the possibility of human error.

Predictive Maintenance: Sensor data is used to flag potential issues and minimize downtime and related costs.

To increase security: These systems can identify potentially dangerous events and act accordingly, taking measures such as turning off a machine to avoid collisions between robots, cars or people.

In practice, AA cannot be used in each and every system. In certain cases, the amount of data that can be collected and processed is limited. On top of this, the cost of adding sensors, processing capacity, power, or interconnection may be too high. Latency is another problem, especially when delays are caused by the fact that data is transmitted expensively and from remote computers or the cloud.

The downside of integrating ML into automation

Beckhoff, an automation vendor, has identified 5 essential requirements for integrating ML into automation, and they are a good starting point:

Open interfaces to ensure interoperability.

ML solutions easy enough that they can be integrated into existing software without requiring any technical knowledge.

ML solutions with a sufficient level of precision and reliability to provide useful results.

Solid training methods that can work with inaccurate data or with noise.

Transparency so that ML systems are simple to understand.

AI and ML projects are quite difficult to start, especially for companies that do not have experience in this field. According to Gartner, "AI projects often fail due to maintenance, scalability, and governance issues." The reality is that there is a big difference between a term test and the implementation of a system in real production conditions. It's all too simple for a project to get out of hand, for expectations to be unrealistic, and for scalable performance not to meet them. In addition to this, the lack of visibility can prevent the managers of a company from knowing the real problems.

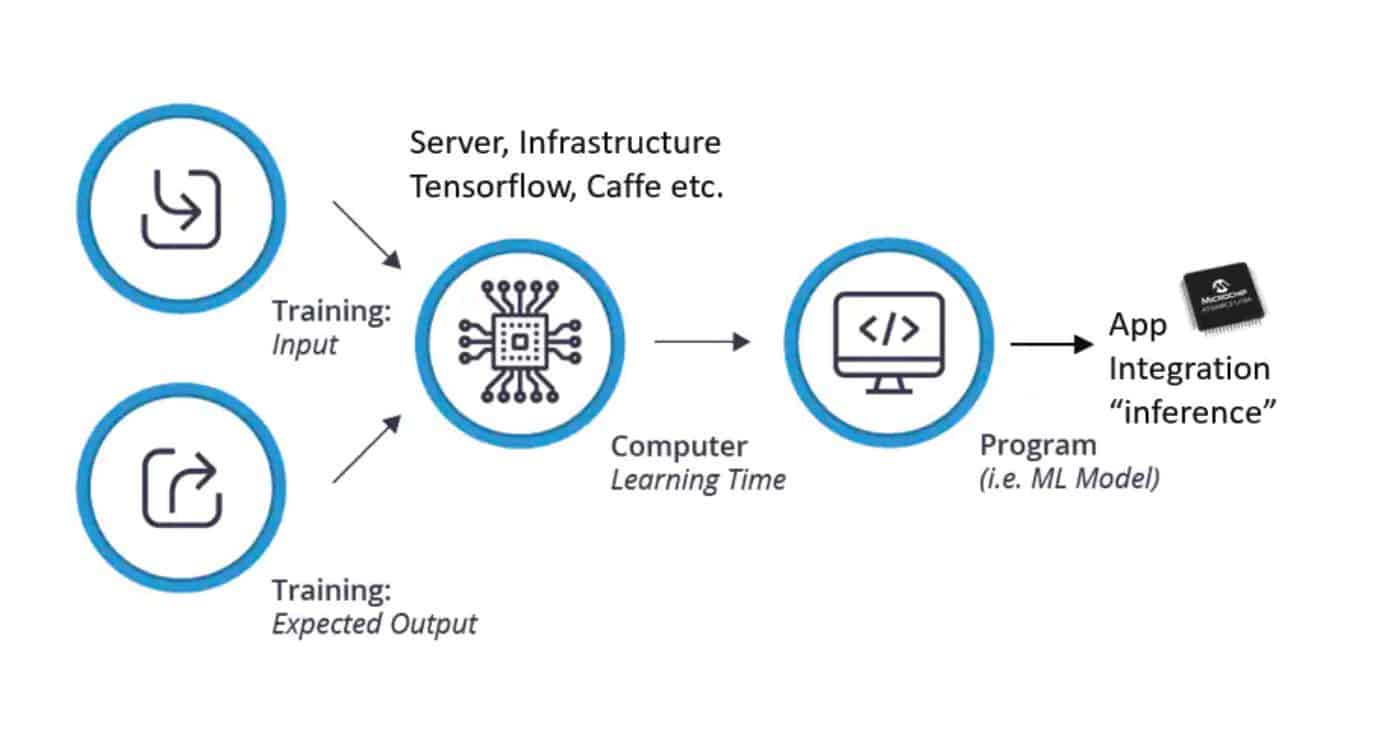

Another vital factor to consider is the practical aspects of implementing an ML system, such as the precise amount of computational performance. This is not always and at all times obvious. In any ML system, there is a difference between the needs of the initial training process and the daily improvement of the model after implementation. The pre-production phase requires exorbitant data sets and a very high level of computing with very powerful computers or servers. However, after the system is deployed in the factory, incremental improvements (achieved by inference, that is, by adjusting the model based on new data) have much lower requirements and can be managed by the embedded processors.

It is better to run ML models in the local field (either with an embedded system or with a PC at the edge) than to send the data for processing to occur in a remote cloud or central server. It is usually faster, the latency is minimal and it requires less demanding bandwidth requirements. In addition to this, it helps to ensure privacy and data security.

Gartner uses an essential term (enabled edge) to describe the organization of IoT computational resources and sensors. In short, "periphery" means that the source of the data is close to the site where it is processed. In this context, "embedded" can refer to the terminal level, with sensors and actuators that could have AC functions.

The AA: what, why, where and how

The AA is not a valid solution for everyone, but it is obvious that it will have advantages in many applications. Why should I use AA? It offers companies the ability to improve their efficiency, scalability, and productivity without significantly increasing costs. In fact, according to IDC, "Businesses won't adopt AI just because they can, but rather because they should." This idea is probably not an exaggeration in the competitive industrial world.

To understand how to start the AA and know what components we are going to need, the first thing to think about is “where”, that is, should we run everything locally in an integrated system or would it be better to do it remotely? on the cloud? It is usually best to do it locally, but you have to weigh the pros and cons, such as cost, latency, power consumption, security, and physical space for computing resources.

In the case of integrated AA systems, there are already many distributors offering suitable processors for industrial applications. Let's see some examples:

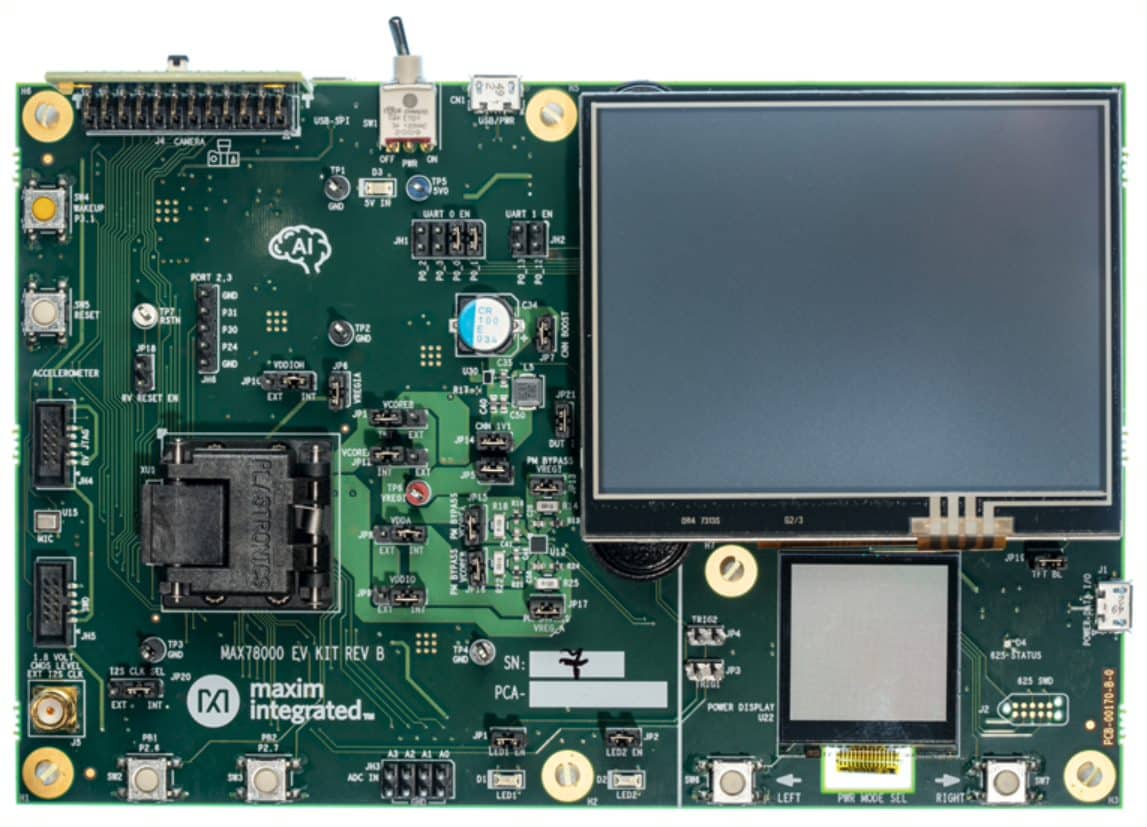

Maxim's MAX78000 is a system on a chip (SoC) developed for AI and ML applications. It contains an Arm Cortex-M4 core with hardware accelerators to run jammers and deliver high computational performance while maintaining low power consumption. Maxim has an evaluation kit and application platform available to help engineers quickly get up to speed and get the most out of the MAX78000.

Another example is Microchip's ML ecosystem, which includes the EV18H79A SAMD21 and EV45Y33A SAMD21 evaluation kits. These kits feature sensors from TDK and Bosch and use Microchip's SAMD21G18 Arm Cortex-M0+ XNUMX-bit microcontroller (MCU).

Another alternative is NXP's i.MX RT1060 Crossover MCU, which uses the Arm Cortex-M7 MPCore platform. It is fully compatible with NXP software and tools, and boasts great CPU performance and a wide range of interfaces.

Conclusions

It is obvious that AA can provide a boost for industrial applications and has the ability to improve manufacturing and other processes: increasing efficiency, scalability and productivity, and keeping costs down.

The implementation of an ML system can be complex and the pros and cons must be carefully weighed. A particularly important resolution is where the computing resources should be: at the edge, integrated into a system, in the cloud, or on a stand-alone server.

There are an increasing number of high-performance embedded processors that can be used to incorporate AA into industrial applications. On top of this, they are supported by an ecosystem of software and development tools from certain more essential vendors such as Maxim, Microchip and NXP. This means that the integration of a suitable processor in the terminals of a production system (ie, close to the data sources) can be a practical strategy to get the maximum benefit from ML.