Andrew Fawcett, Senior Product Manager at Farnell

The COVID-XNUMX pandemic proves the importance of preventing viral transmission in as many ways as possible. Apart from airborne transmission by sprays, contact with surfaces has a significant effect on the infection rates of the SARS-CoV-XNUMX virus and many others, such as the flu, that affect our society. To respond to this pandemic and limit the threat of other viruses that may appear in the future, active decontamination of surfaces in the industrial, medical and commercial environment, as well as in public transport, is essential. UV-C ultraviolet light is becoming an essential tool to achieve decontamination.

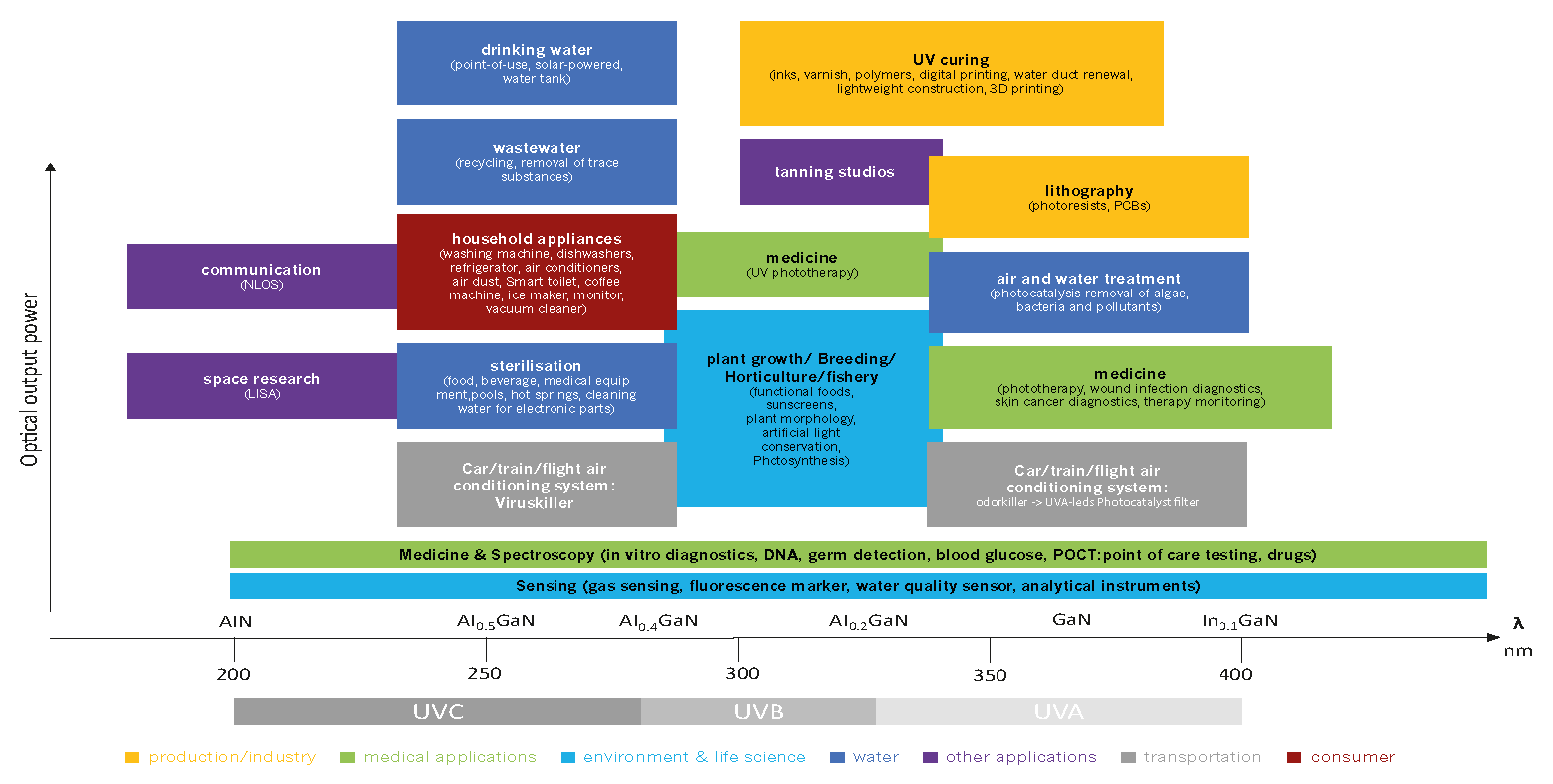

UV-C encompasses wavelengths from XNUMX to XNUMX nm and represents the most energetic part of the ultraviolet band in the spectrum. The ability of UV-C light to inhibit viruses has been known since the early XNUMXth century. Light is very effective in breaking essential chemical bonds in the DNA and RNA of virus particles. This process deactivates them to a harmless state. However, UV-C light also attacks the DNA in our bodies, which has often limited the use of UV-C radiation for sterilization to those cases where the light can be confined, for example, in chambers. sterilization and cleaning compartments in air conditioning units.

Another drawback of UV-C is the cost and availability of light sources based primarily on mercury discharge cylinders, which are not only expensive but also pose a risk of pollution. This has limited the use of this technique to applications where only small areas need to be decontaminated.

Artificial intelligence by sensors in robotics facilitates the deployment of UV-C

Faced with the need to monitor the propagation of the SARS-CoV-dos virus, the approach has altered towards the use of UV-C to treat larger areas. Advances in technology have made it safer, more cost-effective, and more practical to apply UV-C radiation to a considerably greater variety of applications. One essential change is the increasing availability of sensor-based artificial intelligence that can determine when it is safe to use UV-C. An example of this is the application of UV-C to clean elevator buttons. The light source can be set to activate only when the lift is empty, thus ensuring that the buttons are ready for the next user.

Another change is the possibility of using robotics to monitor the application of UV-C, which in turn helps to reduce a key disadvantage of light sterilization: the shadowing effect. Light can only sterilize the surfaces it touches, so it can be quite difficult to fully sterilize a room with obstructing beds and medical equipment. The robots can examine the shapes and calculate trajectories that will maximize the coverage area and combat the effects of shading. Early projects, such as the bus disinfection trials in Shanghai, used manually placed light sources and fixed arrays in a covered area around the vehicle. Nowadays, the use of mobile robots now makes it easier to cover surfaces that would normally be shaded by fixed lighting, such as the backs of seats. Similarly, mobile robots can ensure uniform use of UV-C in a healthcare facility while the treatment area is empty. Even with basic coverage, UV-C treatment has been proven to be more effective than manual cleaning with disinfectants. UV-C radiation can be done in less than ten minutes compared to forty minutes for chemical treatments.

Cost and availability are the key factors

LED technology, for its part, addresses the issue of the availability of cost-effective light sources. LEDs have long been capable of generating ultraviolet light. LEDs are an essential component of many lighting products where white phosphor is used to transform the UV rays generated by a gallium nitride-based LED matrix into usable, perceivable light. However, the shorter wavelengths of the UV-C band require new materials that incorporate gallium nitride.

Today UV-C LEDs use gallium aluminum nitride (AlGaN) instead of the gallium indium nitride (InGaN) used in blue and green LEDs. There are enough elements in common between them to use related epitaxy processes, which means that wafers of gallium nitride, silicon or silicon carbide can be used. The main difference lies in the need for the wafers to be able to withstand higher temperatures during processing. Temperatures up to XNUMX °C are required to deposit high-quality AIGaN crystals via epitaxy.

High intensity UV-C products for decontamination

Manufacturers have solved production drawbacks and are now marketing high-efficiency UV-C sources based on LED technology. Osram Opto Semiconductors released two UV-C LEDs with a peak wavelength of 1 nm. The SU CULBN120.VC is optimized for low consumption in portable applications or family equipment, its bright flux is 1 mW and the angle is XNUMX° of medium intensity. With exactly the same angle of half intensity and an emission of up to XNUMX mW, the SU CULDNXNUMX.VC is suitable for applications that require high levels of UV-C coverage in large areas, such as car cleaning or the large scale air and water treatment.

An essential factor in the design of Osram's products is that it uses a single package. By employing a single package size, the products leave the design of equipment ranges intended for different markets with a single mechanical package. The use of a ceramic pot design gives long operating life and high thermal resistance.

With a 60° angle of medium intensity and an output flux of 35 mW, the VLMU2CL2.-2-XNUMX produced by Vishay Semiconductors is suitable for designs in selective UV-C applications. The CBXNUMX and CTXNUMX in the product range increase the output flux to up to XNUMXmW and XNUMXmW respectively for systems that need to generate higher intensity radiation in the XNUMXnm to XNUMXnm wavelength range. Products in the Vishay range are suitable for industrial applications that require an extended temperature range between -XNUMX°C and XNUMX°C.

For systems that demand certain combinations of output flux, wavelength, and illumination angle, Intelligent LED Solutions (ILS) has developed an extensive selection of products based on TSLC's LED technology. The N3535 and N5050 ranges allow you to choose the wavelengths in the UV-C ranges of XNUMX to XNUMX nm and XNUMX to XNUMX nm apart from the XNUMX to XNUMX nm range. In this way the output can be fine-tuned to target different pathogens.

Optics and measurements are vital in UV-C design

Conventional glass is not transparent, but both quartz and silicon allow UV-C light to pass through. The usual silicon used in other LEDs can break down under intense UV-C radiation, but manufacturers have developed new formulations to keep the silicon alive. A common package design is to join a quartz window and a silicon focusing lens together. To facilitate the design of radiation systems of an area, ILS offers the VIOLET optic from LEDiL. It is an array of twelve silicon lenses that can be potted in conjunction with multiple UV-C light sources and is available in 3 beam angles of XNUMX, XNUMX, and XNUMX degrees to increase design flexibility.

With wavelengths outside the perceptible and health-hazardous range for both viruses, the ability to safely control UV-C emissions throughout the design is a vital requirement. The SDL470 UVA/UVC photometer and data logger from Extech Instruments allows long-term recording of the performance of UV light sources. The data logger has probes for UV-A and UV-C at 1 nm, which sterilants typically produce at lower levels with peaks around XNUMX nm. The sample rate can be adjusted between XNUMX and XNUMX seconds to compensate for long-term recordability and temporal resolution.

UV-C disinfection with the help of LED technology is driving the creation of many novel applications for different markets, but the possibility of incorporating it into designs is going to be vital. Experienced technical dealers like Farnell can offer professional advice and support to help engineers identify the products that are best suited for their applications. Design engineers should consider market leading manufacturers at the forefront of UV-C technology development to locate solutions for their next project. The winning combination of sensor-based artificial intelligence in robotics and automation with market-leading innovations in LED technology has the potential to increase the accessibility of UV-C benefits in healthcare.