This article describes a method for controlling AFR that combines the low cost of a conventional switching oxygen sensor and streamlined catalyst conversion efficiency calibration that allows direct adjustment of AFR amplitude, frequency, and offset. exhaust.

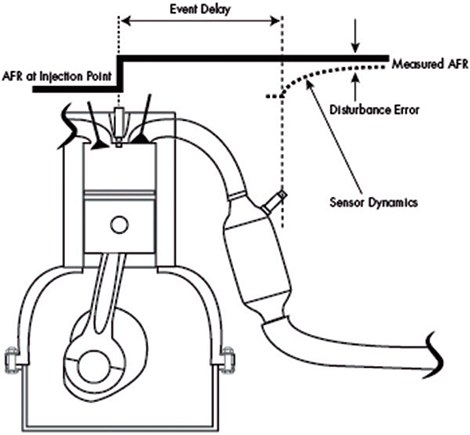

Controlling the air to fuel ratio (lambda or AFR) is essential for improving the performance of an automotive engine and, when combined with a three-way catalytic converter (TWC), significantly reduces automotive emissions. harmful. In order to control AFR, fuel is injected into the intake or directly into the engine cylinder after measuring or estimating the mass of unburned air in the cylinder, and then the injected fuel is corrected according to the measurements of an exhaust gas oxygen sensor located further forward (Figure 1).

In order to simultaneously achieve proper fuel efficiency and low exhaust emissions, a three-way catalytic converter located after the engine converts harmful pollutants into harmless emissions. Catalysts work most efficiently when the exhaust AFR is close to stoichiometric AFR, which is also when the air and fuel burn most completely. Around this ideal point, the AFR is said to be within the catalytic window, in which the catalyst reaches its maximum efficiency in converting carbon monoxide, hydrocarbons, and oxides of nitrogen into non-harmful exhaust products (Figure two). Empirical studies have shown that oscillation of AFR near stoichiometry with optimized AFR frequency, amplitude, and offset widens the catalytic window, thereby increasing catalyst conversion efficiency in the presence of unavoidable perturbations [2].

To keep production costs low, automotive manufacturers design AFR control systems based on low-cost switching oxygen sensors (lambda probes) placed in the engine exhaust before and after the catalytic converter.

The most commonly used oxygen sensors in industry today have a very limited range; basically, they switch between lean AFR (air above stoichiometric ratio) and rich AFR (air below stoichiometric ratio) (Figure 3) [2].

Calibration of traditional proportional integral (PI) control systems designed for these switching sensors can be difficult to calibrate. In particular, finding the frequency, amplitude, and offset that maximize TWC efficiency is challenging, since changing controller gains affects exhaust AFR frequency and amplitude only indirectly. In addition, the effects of changing gains are difficult to assess, since the carry delay (the time between the AFR mixture change and the resulting change in exhaust AFR) varies with engine operating conditions. .

One way to make the relationship between the controller gains on the one hand and the TWC AFR frequency and amplitude on the other more direct is to use a wideband oxygen sensor. This type of sensor provides continuous feedback by determining how rich or lean the mixture is, thus reducing the oscillation of traditional PI control caused by motor transport delay. Wideband AFR sensors are often used in vehicle development, but are generally considered too expensive for use in mass production.

My colleagues and I have designed and implemented a method for controlling AFR that combines the best of both worlds: the low cost of a conventional switching oxygen sensor and streamlined catalyst conversion efficiency calibration that allows direct adjustment of the amplitude, frequency and deviation of the exhaust AFR. This method is based on a concept presented by Meyer et al [3]. We use model-based design to speed controller design, development, and validation in Simulink® and Stateflow®. Using a combination of Simscape™ and the Model-Based Calibration Toolbox™, we built a floor model of an engine for closed-loop simulations, and then generated production code for a Pi Innovo OpenECU M220 engine controller [4] with Embedded Coder.

Design of a period-based AFR control method

In order to develop a method for AFR control that combines the low cost of switching sensors and the easier calibration of AFR frequency, amplitude, and drift provided by broadband sensors, we started with the simple assumption that if we controlled the AFR at the injection point as a sine wave centered on the stoichiometric mixture, the exhaust AFR would also be a sine wave. In an ideal situation, the exhaust AFR sine wave would also be centered on the optimum catalyst AFR (Figure 4). At steady state, the engine gauge directly adjusts the AFR amplitude, frequency, and offset of the injection sinusoid to optimize TWC conversion efficiency. Frequencies, amplitudes, and standard deviations are 0,25 Hz to 1 Hz, AFR 0,25 to 1, and AFR deviation 0 to 0,2, respectively.

In cases where we want the engine to run lean AFR, the sine wave rises, and when we want the engine to run rich, the sine wave falls (Figure 5).

With a lean burn, as the sine rises, the switching oxygen sensor indicates a longer lean time and a shorter rich time for each period of the sine wave.

With a rich mixture, the sensor indicates more rich time and less lean time. The difference between the measured lean and rich times is directly related to how rich or lean the engine is running. Equations 1a and 1b define the relationship between the measured AFR deviation and the rich and lean period measurements used to calculate the AFR controller error.

As stated in Meyer et al [3], injecting a known AFR swing ahead of the engine and then measuring whether the AFR is lean or rich as a function of crossover time at the exhaust side of the engine eliminates the need to compensate for controller feedback gains in relation to unknown and variable transport delays in the motor.

Where:

Clean is the expected number of counts of poor AFR sensor voltage measurements between stoichiometric voltage crossovers;

Crich is the expected number of rich AFR sensor voltage measurement counts between stoichiometric voltage crossovers;

AFRstoich is the stoichiometric air-fuel ratio for the fuel chemistry used in the engine application;

AFRcmd is the average expected air-fuel ratio of the exhaust gas as a function of the average pulse width command sent to the fuel injection hardware;

Acmd is the amplitude of the expected exhaust gas air-fuel ratio as a function of the amplitude of the pulse width command sent to the fuel injection hardware;

fcmd is the frequency of the expected exhaust gas air-fuel ratio as a function of the frequency of the pulse width command sent to the fuel injection hardware;

Δt is the fixed sampling period of the oxygen sensor voltage measurement.

We directly implement the arcsine function from equation (1a) into our Pi Innovo M220 ECU. The arcsine function is not a difficult calculation on a modern floating point ECU.

With equations (1a-b) in the ECU, we can now quantify AFR in a limited range using a switching sensor in the same way as using a system with a wideband sensor.

Developing an AFR Controller Using Model-Based Design

To implement this new concept of AFR control, we use Simulink and Stateflow to model a controller that calculates the expected lean and rich time for a given sinusoidal AFR input, and then outputs an error signal. based on the difference between those times and the times measured by the switching oxygen sensor.

Using Simscape and the Model-Based Calibration Toolbox, we created a mean value model of the motor for use as a plant model in closed-loop simulations of the integral design (Figure 6).

The plant model, which included a lookup table submodel of the switching oxygen sensor features shown in Figure 3, allowed us to perform rapid iterations on our design prior to implementation.

After verifying controller functionality through these system-level simulations for oxygen sensor enable and closed-loop control (Figure 7), we used the Embedded Coder® to generate code for the Pi ECU's embedded processor. I innovate M220.

After HIL (hardware-in-the-loop) testing to check ECU performance in real time, we validated the AFR control system in the engine dyno chamber under steady-state and dynamic conditions , after which the verification was carried out in the vehicle.

We verified on the dyno emissions bench that the Innovo M220 Pi ECU controlled injection AFR to track desired average air-fuel ratios, and furthermore that we could change the exhaust AFR frequency, amplitude, and runout at will. With this capability, catalyst efficiency can be directly optimized by running sweep tests to produce a speed/load table that establishes the optimal TWC AFR frequency, amplitude, and offset based on the points operating speed and engine load.

The period-based approach to AFR control allows much faster and easier calibration of catalytic efficiency than the traditional approach of iteratively adjusting proportional and integral gains to indirectly produce the desired frequency and amplitude.

Products used

• Simulink

• Embedded Coder

• Model-Based Calibration Toolbox

• Simscape

• State flow

About the Author

Pete Maloney is a Senior Principal Technical Consultant with 24 years of industry experience in advanced engine control system development, design and calibration.

Pete chairs the Powertrain Control and Calibration World Congress Session as well as co-chairs the Society of Automotive Technical Engineers (SAE) Control and Calibration Committee. He has a BS in Mechanical Engineering from Texas Tech University and an MS in Mechanical Engineering from the Massachusetts Institute of Technology.