“The LabVIEW software allowed us to implement a controller in real time and in the same Windows environment, which offered us a fast integration and a reliable stand-alone product, especially optimal for the control of preset parameters and for the minimization of risks in industrial processes."

The challenge:

Develop a program that allows to modify the parameters of a Programmable Logic Controller (PLC) and that runs under Windows environment easily parameterizable and scalable to have control of the productive processes in industrial machines of the agri-food sector and the surface maintenance sector.

The solution:

Use LabVIEW as a development environment due to the ease of integrating the different needs of the system: data capture, database management, Web access to applications, user interfaces... In the acquisition part, the Supervision, Control software is interconnected and Data Acquisition (SCADA) via ethernet or wifi with industrial machinery that works under a PLC.

Introduction

The IRIS Advanced Engineering area has extensive experience in the development of control and diagnostic systems in an industrial environment. These systems require the capture of signals of a diverse nature such as the temperature of food products, their humidity, high and low frequency electrical and digital signals, pressure, vibration, among others. In addition, these systems require high storage capacity because in many cases they run continuously for the entire production.

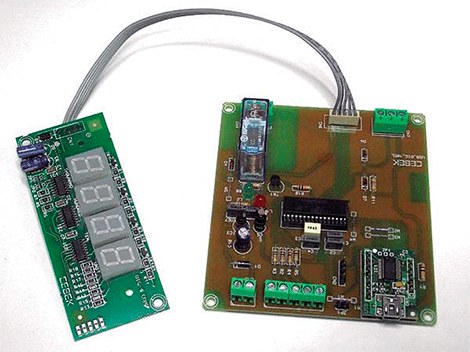

IRIS has adopted LabVIEW for its recent technological developments through ultrasound systems for the agri-food sector. In addition, the eco-treatment developed by IRIS to increase the durability of wood was also successfully monitored through LabVIEW. All the pre-industrial and industrial machines to which LabVIEW has been incorporated work under PLC systems, with the exception of the rapid cooling system for freshly cooked meat, whose technology includes microcontrollers. The non-thermal milk pasteurization system developed by IRIS with the LabVIEW user interface, this pre-industrial prototype combines the methods of thermosonization and electrical pulses. The non-thermal pasteurization system parameters the temperature and the flow of milk to be treated.

The multi-sensor online diagnostic solution uses stand-alone diagnostic equipment located on each machine, a distributed MySQL database, and a central server. Access to data can be decentralized as the user interface is adapted for use through a Web browser. The LabVIEW Web Server allows you to develop user applications as if they were to be used locally and then publish them via the Web. Therefore LabVIEW can be used as a single development tool integrating data capture, signal processing and interface design regardless of where each of these functions are installed, the type of communication between them and how they are going to be used by users. the end user, in industrial environments.

The agreement between LabVIEW and Allen Bradley is very useful in providing a specific tool that ensures effective communication between the program and the system.

diagnostic app

Since the dynamics of the failures to be studied is relatively slow, the system performs data capture in rounds and subsequently processes the data obtained.

In each of the rounds, different captures (channels and frequencies) are made based on the programmed diagnoses. All the results are stored in the local database and only the most significant ones or the alarms are sent to a central database. In the event that there was an error in the production process, it would be possible to know the precise moment in which it occurred and identify the possible causes. LabVIEW provides detailed information to facilitate the work of the end user. The application structure is made up of several modules. The LabVIEW module is in charge of reading the configurations of the database (MySQL) and of the PLCs of each machine. Depending on the parameters collected, the execution of the captures is ordered at the scheduled moments and later the processing and diagnostics when there is available data. The LabVIEW user interface allows access to the captured signals, diagnostic results and simple analysis functions such as the FFT visualization of one or several of the captures, being able to compare them to make the respective decisions.

Any user will be able to connect to this interface via the Web, without having to download the captured data. The modular design allows easy modification of the processing algorithms at runtime and even adding new ones without the need to recompile the entire application. In this case, the algorithms are found in a dll library that can be modified at any time when processing is not running on the system.

diagnostic network

The LabVIEW system allows managing the mechanisms in order to keep each of the databases updated. Even if communication is lost at any of the points, all the machines continue to carry out the programmed diagnostics autonomously.

The end user of the application has access to all the diagnostic information generated in the different machines quickly and flexibly. To this end, a SCADA-type user interface has been designed, located in the central server and accessible through any Web browser. Whenever the user wants to access the captured signals or analyze any of them, they will do so transparently by connecting to the interface located on the machine instead of the one located on the central server.

Conclusion

IRIS has chosen LabVIEW as the development environment for the whole of this control and diagnostic application. This has allowed the integration of modules from the research/development stage to the final application stage easily and without additional cost. This modular conception facilitates the software development process by designing the modules (capture, processing and diagnosis) independently and later being able to execute them on different computers depending on the requirements of the calculations and the performance of the equipment used. The system has been implemented in four prototype machines designed and developed by the IRIS engineering team, in collaboration with European consortiums, with more than 30 companies altogether.