The 8X version of the NXP i.MX 8 processor has extremely low power consumption, is robust and comes with many functional safety features. It is now supported in congatec's SMARC 2.0 and Qseven module standards. Such modules offer ARM developers greater design security and easier implementation of the processing core despite increasing complexity.

As NXP's flagship processor, embedded system developers have always taken the new i.MX 8 processor into consideration. It is the most powerful in the entire i.MX 8 family. Next to it, the new i.MX processor family 8X is now also available. It extends the scalable range of the i.MX 8 series with a particularly robust and low-power processor variant with 2 to 4 ARM® Cortex®-A35 processor cores, with optional SIL 3 certification. Applications for this particularly robust and energy-efficient new 8X variant can be found, among others, in industrial devices, machines and systems that demand a high level of functional safety.

Integrates the most efficient ARM cores

At the same time, these new 8X processors, which integrate the most efficient ARM cores ever, are also suitable for the extended temperature range from -40 to +85°C, making the new class of processor ideal for outdoor and mobile vehicle applications. With a power consumption of less than 3 watts in normal operation and a maximum TDP of 3-4 watts, such systems are also suitable for completely non-forced ventilation and solar powered applications. Thanks to the high degree of integration of graphics, video, audio, and voice, the new processors are also very attractive for implementation in HMIs, rugged tablets, and handheld devices. Integrated image processing functions further predestine the new processors for video analytics and the use of neural network technology for object recognition and situational awareness applications.

Multi-talent focused on the mobile segment

Application options are very diverse and range from smaller industrial automation and control systems, such as PLCs, I/O controllers, robotics, and logistics and distribution systems; for building management systems, patient monitoring systems, automotive and intra-logistics cabins, and inflight infotainment on planes and trains; for IoT, M2M and telematics applications with distributed devices of the most diverse designs, as well as distributed intelligent video surveillance systems. If these devices are equipped with the new i.MX 8X, they offer better performance than was considered the best tablet performance until a few years ago. As they become more and more attractive in terms of price, they are opening up an increasing number of new application fields and markets.

High scalability pin and software compatible

Since the new NXP i.MX 8X processor integrates all of the highest value i.MX 8 family core architectures and subsystems, developers benefit from an extremely wide range of scaling options and maximum software reusability. But what are the differences between i.MX 8 and i.MX 8X? First of all, it should be noted that neither variant has anything to do with the i.MX 8M, which is already available in series production. This has been developed as a device for set-top boxes and TV systems and is therefore positioned in the consumer electronics segment, which has a completely different application focus than industrial facilities, where LVDS support is still an issue. an important feature among other things. Only the two variants i.MX8 and i.MX 8X, for which companies such as congatec provide support at the embedded board and module level, will be compared below.

Fine but safe processing cores

In addition to the already mentioned optional SIL support offered by the i.MX 8X, another difference is the use of ARM Cortex-A35 cores instead of ARM Cortex-A53 cores. No ARM Cortex-A72 processors are used and the overall feature set is cheaper and therefore more energy efficient, reducing the power consumption of the i.MX 8X to 3-4 watts compared to 12 watts for the fully equipped i.MX8. The i.MX 8X is available in configurations with 2 or 4 Cortex-A35 processors along with 1 Cortex-M4F with integrated floating point unit and DSP to process critical tasks such as backup camera as well as system monitoring and activation. . The i.MX8, on the other hand, offers a total of up to 8 cores (4x A53, 2x A72, 2x M4F) and comes with a remarkable feature set including high-bandwidth and energy-efficient LPDDR4, as well as also optional DD3 with ECC.

Powerful and reliable graphics

The i.MX8 supports up to 3 independent displays, as well as 1x SPDIF and 2x ASRC audio, including full codecs for voice recognition and contactless interaction. Two of the screens are compatible with Full-HD (1080p) and one in WVGA (864×480). The integrated video processing engine supports decoding and encoding of 1080p video in h.264, as well as decoding of even higher resolution 4K video in h.265. Another important feature is hardware-based resource partitioning, which allows separate processors and graphics cores, making it possible for multiple independent applications to run on a single chip. Combined with hypervisor support, developers have great flexibility when building reliable systems. An important feature, for example, for vehicle applications: if the infotainment system fails, the rear view camera continues to function safely in s / w mode. The same principle can also be applied to control systems in automation.

A rich selection of interfaces, including real-time Ethernet

The core also runs 1 PCIe 3.0 interface for flexible expansion options, as well as 1x USB 3.0, 2x USB 2.0, 3x CAN, 4x UART, 4x SPI and 1x 12 bit AD interfaces. The two provided Gigabit Ethernet interfaces are ideal for horizontal and vertical networks in automation. Optional support for 1588-compliant real-time communication via TSN protocol makes the core of Industry 4.0 and IoT ready so multiple robots/welding arms in a production cell can be synchronized in real-time via ethernet. In the case of the i.MX 8X, this support can be done by using an additional Qualcomm Atheros device, an option available for congatec modules. Audio Video Bridging (AVB) also supports video streaming over Ethernet, which is interesting for digital signage players and surveillance cameras connected via GbE.

Image recognition and deep learning

For video-based applications, the i.MX 8X supports a 4-channel MIPI-CSI interface, among others. GPUs with 2-4 Somb4 Vec4 (1x GC7000Lite or 1 x GC7000UltraLite) also support OpenGL ES, OpenCL, OpenVG and Vulkan for parallel data processing in addition to graphics output. The focus is on situational awareness applications with image recognition, as well as artificial intelligence and deep learning applications for machine learning. If you're missing anything from this extensive feature set of the i.MX 8X, you can safely assume that the i.MX8, as the larger version, will offer more in every feature category.

Many reliability and safety features

In general, both processor variants also offer higher reliability thanks to fully developed Silicon on Insulator (FD-SOI) manufacturing technology. It helps application processors built on the 28nm process to dramatically improve MTBF compared to previous technologies, and reduce latch-ups thanks to FD-SOI's high immunity to soft defects. All of these features, along with sophisticated security features such as high-security boot, TPM timer, full encryption, and up to 10 active and passive tamper pins, make the new i.MX 8 processors an ideal foundation for development of embedded computing platforms that are extremely energy efficient and highly reliable.

Easy implementation of complex technologies

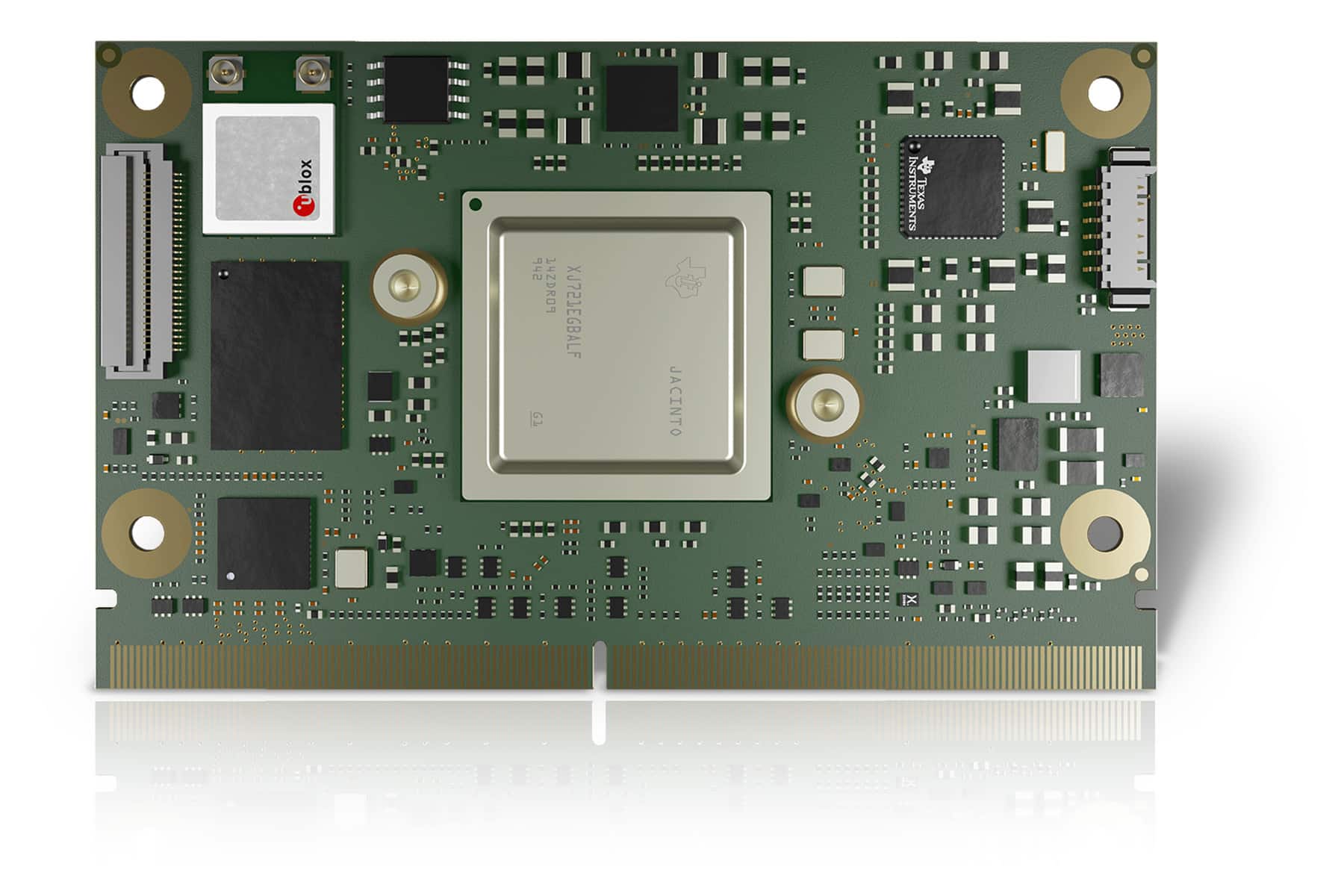

Device developers in this small form factor segment often face the challenge of needing a specific design, but none of the existing standard boards meet their demands. As a general rule, standard boards do not provide the required performance, nor do they offer the necessary interfaces to start application development directly. That is why developers look for the most efficient way to develop their solutions. Will they have to develop everything themselves or can they also use off-the-shelf components? And if so, what should they wear? Since the computing core is first and foremost a means to an end and does not require any further adaptation, industry standard CoM (Computer-on-Module) modules such as SMARC 2.0 or Qseven are recommended. With these application-ready modules, the powerful computing core can be installed with a simple plug & play, and bingo, developers immediately benefit from a drastically simplified design, where all that's left to do is tweak. the specific interfaces on the motherboard. Standard CoM modules are also ideal for fully custom designs, as the compute core can easily be combined with motherboards. A particularly important advantage of using modules is the fact that they can be scaled from i.MX8-X to the high-end i.MX8 Quad based on SMARC 2.0 or Qseven, although the processors are not pin-compatible and therefore therefore require their own specific design.

Instantly ready to go

Therefore, developers can immediately start designing their applications based on an evaluation support board and the extensive ecosystem of software that comes with the board and modules in the form of custom bootloaders and BSPs. Based on the motherboards, early prototypes and small series can be developed and the compute core can be fused with the motherboard from balance design to fully customized design. Since the computing core comes application-ready, project risks are reduced from the start. Another advantage of CoM modules is the fact that they can be made available for evaluation purposes prior to serial production on NXP by companies such as congatec. Those who follow first-to-market strategies for their i.MX8-based system designs will be well served by congatec's SMARC 2.0 and Qseven cCoM modules. As super components, they combine everything an i.MX8 application developer needs into a complete application-ready package and are very easy to implement right up to fully custom designs.

Support is crucial for standard products

However, if you want to go from a standard product to a platform optimized for a specific application, using the correct hardware platform is only half the battle, especially if it's an ARM processor-based design. For this reason, congatec offers a complete software ecosystem for its standard components, which is provided as standard together with the hardware and is accompanied by personal integration support for OEM developers to make their tasks easier and more efficient. . At the same time, congatec also positions itself as a full-service provider for all OEM embedded computing needs. The congatec Technical Solutions Center (TSC), which is responsible for additional services related to the hardware platform, therefore offers a wide range of suitable solutions. TSC services include everything from the bootloader

and UEFI customization to any custom firmware development, as well as any Linux (real-time) questions and custom projects with QNX or Green Hills. The service offering also includes the selection of suitable motherboard components, for example for SIL certification of the system design, as well as high-speed signal compliance testing, thermal simulations, MTBF calculations, and debugging services for solutions. customer specific. The goal is to always provide customers with the most efficient and convenient technical support, from requirements engineering to mass production.