By Mark Patrick, Mouser Electronics

Why don't we charge each and every personal device wirelessly? Power cables are cumbersome, and it really wouldn't be hard for the industry to do away with them. Things are already being done in this regard: many of the mobile phones that come onto the market can be charged without a cable and many new vehicle models can charge devices of this type. On top of this, this technology is being tested in bars and cafes all over the world, and there are a large number of test beds for all kinds of wireless charging systems.

Taking all this into account, why hasn't the use of wireless charging been widespread? The main drawback is that there are different standards. The Qi standard, from the Wireless Power Consortium (WPC) and the different standards of the AirFuel Alliance have been competing for years and using different technologies, so manufacturers cannot be sure that the user will be able to charge easily and from anywhere. place your mobile, smartwatch, tablet or laptop.

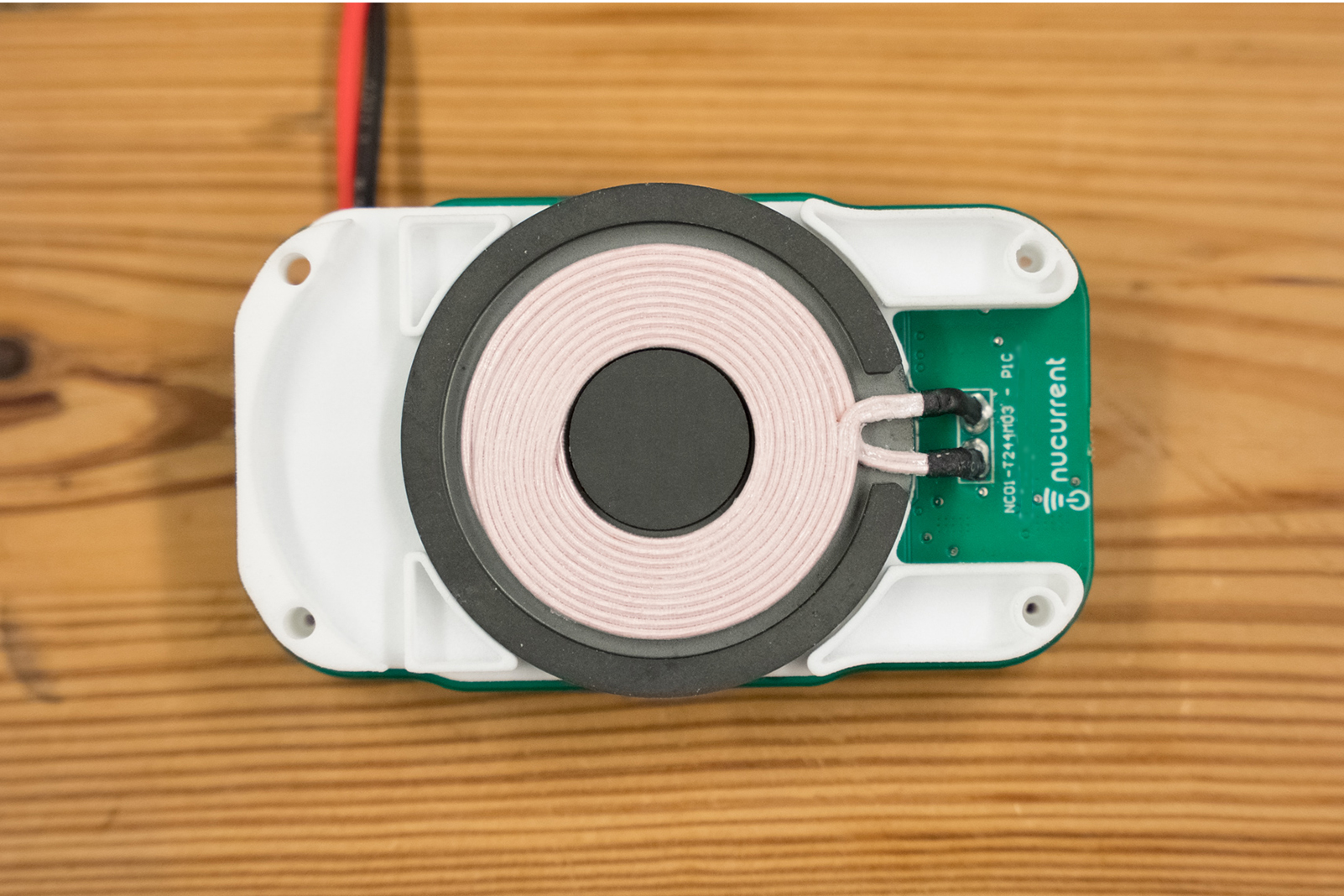

There has also been some problem related to the technical design. In Qi systems, the charging coils of the transmitter and the receiver must be separated by a few millimeters and aligned in the appropriate way so that the charge is faster, something that does not happen at the first change when the user puts the mobile on a loading table.

The device and the charger must communicate, which can be achieved in different ways. There are also many options for the charging technology itself—from inductive and capacitive charging to MRI—and each has its engineering drawbacks and benefits. In addition to this, the user wants the charge to be fast, which implies a greater power; In turn, this can cause security issues in wireless topologies, since metal in the area could become hot and cause injury. Another important factor that should not be forgotten is that manufacturers will always try to keep the total cost as low as possible.

Introducing the WPC

The WPC is an open cooperative group for the development of standards that was formed in XNUMX and is made up of more than XNUMX companies from all over the world (although, in the field of wireless charging, a large number of companies cooperates with organisms that compete with each other). Shortly after their training, this team introduced the Qi (pronounced "chi") standard, the most established technology for mobiles and portable devices with power between XNUMX and XNUMXW. However, to some extent, this has been a challenge. obstacle to modernization of the standard, as innovations have to be compatible with systems that were designed ten years ago.

The Qi standard employs the cheapest methodology: an inductive charging mechanism, strong coupling, and low frequency. However, the WPC has expanded its proposal with a wireless standard for household appliances (from 2 W to XNUMX kW) and another of medium power for tools, robot vacuum cleaners, electric bikes and other battery-powered devices (from XNUMX to XNUMX five W). Both are still in development and use different technologies to get around the backward compatibility issue.

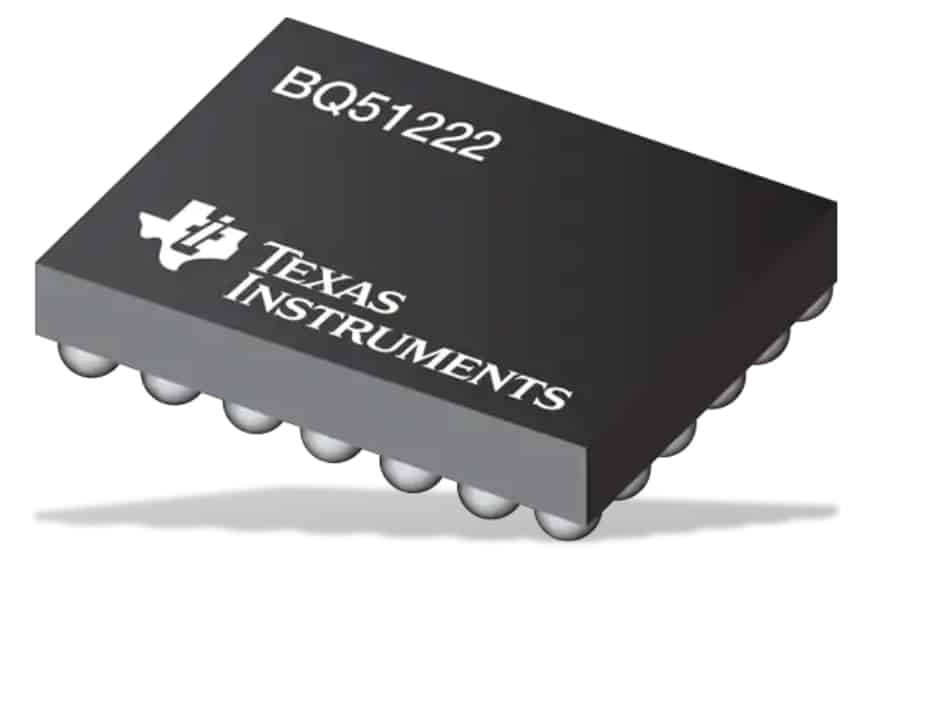

The Qi standard works with a low frequency band communication (112 to 250kHz) and with a low data transmission speed. This limits the load spacing (5-XNUMXmm) and clearly affects positioning flexibility. In band communications, data is used to send as well as wireless transmission of nutrition. The drawback is that this only works one way (from receiver to transmitter) and only when there is only one receiver associated with one transmitter. This can be solved in different ways (with many independent coils, or with a set, and with different communication protocols), but they have other disadvantages, such as backwards compatibility and increased cost. Many single-chip Qi controllers are being manufactured (such as those from Texas Instruments and NXP), which is helping to reduce the cost of simple wireless connections.

AirFuel Alliance

The merger of the Alliance for Wireless Power (A4WP) and Power Matters Alliance (PMA) in 2 marked the birth of the AirFuel Alliance, managing to combine 6,78 rival technologies: capacitive and resonant charging, which contributed to reducing fragmentation in the wireless charging planet AirFuel uses a flexible structure with a higher frequency (5Mhz), apart from backscatter between the coils. Thanks to this combination, multiple devices can be charged at the same time and from a single transmission coil, with flexible orientation and with distances of up to XNUMXcm, more than the Qi standard.

With backscatter, the transmitter can determine changes in the transmit coil charge caused by disturbances in the receive coil charge. By encoding the data in changes in the charge of the receiving coil, it can send a signal to the transmitter, which, with the help of a demodulator, will be able to access the data. Thanks to backscattering, easier positioning and the possibility of using greater distances, the transmitter coil can be placed under the surface of a piece of furniture, which facilitates the loading of the user and the integration of the technology in the systems of the distributor of services. Loosely coupled also allows for higher power use (XNUMX+ W) for faster charging, but is more difficult to incorporate than tightly coupled topologies.

AirFuel's Magnetic Resonance Working Committee (MRWC) is charged with developing and maintaining technical specifications on magnetic resonance technologies for wireless power transfer. Part of his job is to create conformance test requirements and interoperability test scenarios for rumbling and multimode systems. On the other hand, the Non-Coupling Technologies Working Committee (UWC) develops and maintains technical specifications for nutrition and wireless charging through non-magnetized methods, such as RF, ultrasound and laser, capable of providing energy to a considerably greater distance.

An essential feature of the AirFuel standards is out-of-band communication. This enables continuous communication to be established and sustained between the wireless power transmitter and the relevant receiver. It is possible to send auxiliary information between the relevant elements of the transmitter and the receiver, for example, the load capacity of the device in question (in order to use the highest possible rate), authentication, etc. This is because out-of-band communication does not depend on nutrition transfer. In this sense, different communication protocols can be used, such as Bluetooth Low Energy (BLE) or Zigbee. AirFuel advises using BLE (4GHz), as it can accommodate multiple receivers for a given transmitter. It is also compatible with devices that require different levels of nutrition, greater freedom in terms of space and distance, authentication security, low power consumption and many other intuitive features for the next generation of devices in the Internet of Things (IoT). .

However, the WPC is not going to let everything continue according to the script set by AirFuel. The latest specifications for the Qi transmitter (MP-A16) already allow charging via surfaces. This means that practically any surface can be transformed into a wireless charger and that it is considerably easier to adapt the "hardware" to be able to integrate it into tables, counters, etc. The system consists of a transmitter coil that is installed under a surface and a repeater above, as well as the interfaces for the receiver. By using a repeater to direct the flux generated by the transmitting coil, the system can be installed under surfaces that are between 30 and XNUMXmm thick.

The MP-A16 transmitters are fully compatible with the base of WPC receivers, both those of a Basic or Low Power Profile (BPP) and Extended or Intermediate Power Profile (EPP), up to a maximum of fifteen W. The benefit of all this is that existing Qi devices could use a charging surface by installing an MP-A16 transmitter.

The previous experience of the WPC in the implementation of charging networks revealed a major obstacle to the proliferation of charging infrastructure: the obligation to drill the surfaces. It is a complicated and also irreversible job, so a large number of owners are quite reluctant to leave it in their facilities. With the MP-A16 transmitters, the installation of wireless chargers will be considerably easier: just put a transmitter under the table and a repeater on top.

The WPC is also meant for charging outdoors. Wireless charging in these places is especially difficult, since conditions can change a lot throughout the year (extreme cold, extreme heat, sun, rain, hail, snow, etc.). The input power must also be 24 and 5V, and not just XNUMXV. It is also essential to use waterproof potting techniques in order to prevent the ingress of moisture and ensure the safety of the charging equipment, the device and, above all, the user.

Outdoor charging facilities are already being built around the world, for example in the Czech Republic, where a surface-mounted Qi wireless charger has been integrated into a solar park bench. The WPC expects the frequency of these installations to increase as users trade in their old phones for newer models equipped with Qi charging capabilities.

Today, there are already many attractive options for developers of wireless charging systems. Until now, however, manufacturers had to develop devices compatible with each and every one of the protocols. For example, Semtech's TS80000 is a transmitter capable of managing power outputs of up to 40W and is compatible with Qi, AirFuel and certain proprietary protocols. It can be configured to power single or multi-coil applications (half-bridge and full-bridge systems), decode bundles of the secondary device, and adjust control accordingly. An integrated PID filter provides precise compensation to the circuit in order to achieve greater precision in the control of the duty cycle, the frequency or the voltage of the bridge.

From what is seen, it does not seem possible that these 2 sets of standards will be merged. The two are developing similar standards, but from different directions. For their part, semiconductor manufacturers can't afford to rely on one option, so they combine the protocols on programmable chips to give developers as much flexibility as possible.