With traditional instrumentation, approximately 40 significant data points from a WLAN transceiver were acquired per iteration. The increase in the speed of the NI PXI vector signal transceiver allowed the triggering of sweeps to obtain the complete gain table acquiring 300.000 points.

"Using NI's software-designed PXI vector signal transceiver and the NI WLAN Measurement Suite, we've improved test speeds by more than 200 times compared to traditional instruments, significantly improving test coverage."

The challenge:

Reduce the cost of wireless local area network (WLAN) testing and increase its accuracy while reducing characterization times as device complexity grows with an increasing number of wireless standards.

The solution:

Using the PXI-based vector signal transceiver and the NI LabVIEW FPGA module to create a flexible custom WLAN test system that offers more than 200 times reduction in test time compared to traditional instruments, resulting in about lower testing costs and better device characterization.

Introduction

For more than two decades, Qualcomm Atheros has been a leader in next-generation wireless technologies for consumer electronics, networking, computing, and mobile communications. Today, high-performance wireless technologies such as WiFi are being developed to meet the demands of new connected applications. The latest Qualcomm Atheros chip features a Tri-Band Multi-Input/Multi-Output (MIMO) transceiver for the new 802.11ac WiFi standard.

Requirements for a new WLAN test system

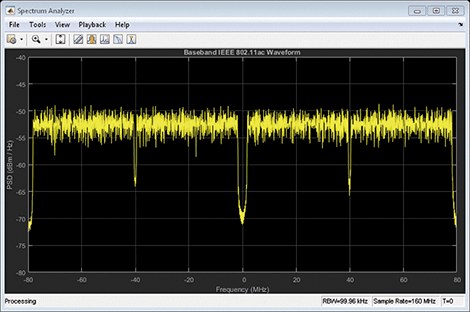

As wireless standards become increasingly complex, the number of modes of operation for these devices is increasing exponentially. As we progress toward the latest 802.11ac WiFi standard, we are adding new modulation schemes, more channels, more bandwidth settings, and additional spatial information transfers. Furthermore, the characterization of WLAN transceivers is especially difficult when dealing with thousands of operating gain settings that are independent.

Each component of a WLAN transceiver has multiple gain stages. To develop a high-performance radio in a low-cost CMOS process, the Qualcomm Atheros design team relies on flexible operation for each stage of the radio structure. The multiple gain settings lead to a geometric increase in the number of possible setting combinations each time a stage is added, resulting in hundreds of thousands of data points for a single mode of operation. These hundreds of thousands of data points are for a single radio transceiver only, and the number of permutations continues to increase for MIMO configurations where the system uses multiple antennas. This geometric increase in the number of possible fit combinations also poses a significant challenge in preventing the increase in testing times.

Vector Signal Transceiver PXI and LabVIEW FPGA

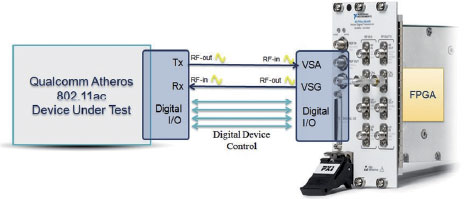

To address the challenges of test times, Qualcomm Atheros uses the NI PXIe-5644R vector signal transceiver. Because the NI PXIe-5644R incorporates an onboard FPGA, the digital interface to the chip can be controlled at the same time as the RF signal generator and analyzer included in the vector signal transceiver.

Traditionally, FPGAs have been programmed using the VHSIC or Verilog hardware description language. Many engineers and scientists are not well familiar with these complex languages or require a tool that gives them higher design productivity with a higher level of abstraction to simplify the FPGA code generation process. LabVIEW is well-suited for FPGA programming as it clearly represents parallelism and data flow, so users with or without experience in traditional FPGA design can effectively apply the power of reconfigurable hardware.

Qualcomm Atheros uses LabVIEW in programming the NI vector signal transceiver FPGA for DUT control and data processing. Processing can be carried out within the instrument itself instead of requiring transfers back and forth to the controller via the bus, resulting in much shorter test times.

Traditional measures based on traditional instruments are limited to the best picks within an estimated payout table. With this setup, the Qualcomm Atheros team determined the final solution using iterative estimates, each requiring a regression of the gain characterization table.

This was a slow process, producing about 40 significant data points per iteration. After switching to the NI PXI vector signal transceiver, all gain table sweeps could be performed, instead of using the iterative method, due to improved test time.

The team was then able to characterize the entire radio operating range with a single test sweep per device to acquire the full 300.000 data points needed for the best empirical determination of optimal operating parameters.

The availability of this data gave us insights into the operation of the devices that we had never seen before, as the team was able to explore operating regimes not previously considered.

By synchronizing the digital control timing directly with the RF measurements, we have seen test times reduce by more than 20 times over our previous PXI-based solution and up to 200 times over the original solution using traditional instruments.

Improved test freedom, flexibility, and performance

At Qualcomm Atheros, instrumentation flexibility and pin-level control are critical to keeping the RF test process as efficient as possible, and we're very pleased with the performance improvements we've seen in testing with the new NI vector signal transceiver.

The NI PXIe-5644R provides freedom and flexibility as we develop 802.11ac solutions for our customers and has significantly improved test performance.