Wearable technology opens a new path to the development of embedded systems, presenting a set of very disparate technologies and facilitating their acquisition through new ways. Wearable technology enables new types of user interfaces never before used, making computers and electronic components more responsive to the wearer by providing important data on their overall well-being.

The problem for startups has centered on the difficulty in prototyping and supplying wearables for pre-series. The need to integrate electronic components in clothing, or in bracelets and belts imposes limitations in terms of design forms. Still, it is possible to use conventional development systems, although they are often too bulky in pre-series utility. For example, a system designed for sleep analysis can itself be uncomfortable, giving misleading results. Wearable applications typically require platforms that combine processors, sensors, and wireless communication to be able to process the data and transmit it to a device, often a smartphone that the user is carrying or nearby. The wireless connection allows a device to capture data from sensors located on different parts of the body. Developers have to choose between different wireless connection options, such as Bluetooth Smart and 6LowPAN or also between the IEEE 802.15.4 or IEEE 802.15.4a standards, operating in the 2.4GHz, 433MHz or 868MHz bands. One advantage of Bluetooth Smart is that it works with virtually all smartphones and tablets. Recent changes to the Bluetooth protocol have improved the consumption of the wireless interface as well as the security of the connection, supporting applications with personal sensors that need data privacy. Although it seems that Bluetooth technology prevails as a suitable option to develop projects with wearables, there are alternatives that provide additional functions. Based on ultra-wideband (UWB) technology, the IEEE 802.15.4a standards provide not only communications for sensor networks, but also the possibility of highly accurate location indoors. Many wearables will process physiological data recorded by sensors designed to capture movement, heart rate, skin temperature and also environmental data such as pressure. Sensor fusion is an important aspect in wearable design and software development to increase the usability of devices by combining inputs from different sensors. Such sensor fusion increases the environmental awareness of wearable devices. Forward movement, captured by accelerometers and gyroscopes, accompanied by an increase in heart rate can indicate that the user is running or walking, all without the need to press buttons or input a screen to tell the device which mode it is in. You must find. There is a growing trend towards sensor combo modules to help developers create off-the-shelf solutions that previously required application-specific integrated circuits (ASICs). An example is the Osram SFH 7050 BioMon sensor, developed to respond to the demand of the fitness and well-being wearables sector, which includes three types of integrated LEDs together with a photodetector.

The green LED is used for pulse measurement on the wrist, while the red one works best for pulse measurement on the finger and also for measuring blood oxygen saturation. A nearby infrared LED can act as a proximity sensor so system software can decide whether to start or stop measurement logging. The integration of multiple LEDs facilitates the operation of sensor fusion. Some fitness devices on the market use a combination of reading photodetectors from different LEDs to detect the pulse rate. If the readings from the different sensors are consistent, they give greater confidence to the overall results. For example, in addition to using the change in absorption of green light by the increased amount of blood under the wrist, it is also possible to use infrared. Elevated blood pressure increases the pressure around the sensor, which changes the amount of light received by the optical sensor. Similarly, in a pulse oximeter, the infrared sensor, along with the red light sensor, improves the overall quality of the data. Deoxygenated blood tends toward the blue color, which preferentially absorbs red light. Highly oxygenated blood does not absorb as much red light but tends to show more absorption in the infrared spectrum. The crossover in the absorption characteristics thus acts as a useful confirmation that the oxygen measurements are of high quality. Overall power consumption is important in determining the sensor performance of a wearable device. There is often little space to fit a large battery in the body of the device.

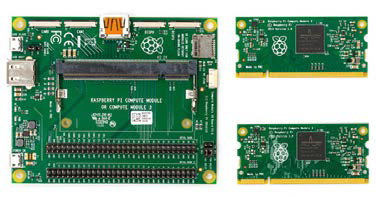

To improve power efficiency, many developers take advantage of sleep modules available in low-power microcontrollers such as those based on the ARM Cortex-M architecture or Texas Instruments' MSP432. Although it may seem to the user that the sensors of a wearable are continuously monitoring the inputs (movements, environmental data and physiological data) this does not mean that a high sampling frequency is necessary. Some inputs only need to be sampled a couple of times per second, and perhaps up to a hundred in the case of high-resolution samples. The input processing time, even with sensor fusion computations, will typically be short compared to the time between samples, the MCU can go into sleep mode for long periods of time. Low duty cycle helps minimize power consumption and improve battery life. Aesthetics will be important in the case of end devices, so it is important to be able to move away from the rectangular shapes of embedded boards. The Arduino Lilypad board is a good example of this. The electronics, compatible with the Arduino development environment, are mounted on a round PCB that has holes designed to make it easier to sew onto a piece of clothing.

Another similar option is Adafruit Industries' Flora platform, slightly smaller than the Lilypad, though it has more sensors and built-in communication functionality, just as it has more memory, but fewer custom I/O channels. With its diminutive size, the Intel Curie processor presents another option for designing wearables that fits into many types of wearable builds. Little larger than a shirt button, the rectangular module integrates dent

ro of it a full 32-bit Intel Quark processor, a six-axis motion sensor, Bluetooth Smart communication, and 384KB flash memory. Designed in collaboration with Intel, the Genuino 101 development and learning board offers the performance and low power of Intel Curie with the simplicity of Arduino at an affordable price. The advent of 3D printing can further aid design and low-volume prototyping and pre-series. Using free software such as DesignSpark Mechanical, shells for boards such as the LilyPad can be quickly designed and manufactured in such a way that the electronic components and sensors are protected while the part wears out. Other wearable prototyping systems claim to be closer to end applications. For example, the TI Chronos developer watch offers a platform based on the MSP430 microcontroller with a display out of the box, but can be disassembled for replacement with custom applications.

The core unit includes a pressure sensor and an accelerometer for motion detection, as well as a wireless transceiver to transmit data to a smart hub. Combining off-the-shelf devices with easy access to 3D printing technology and a growing variety of sensors, development and prototyping for wearables is now easier than ever. The trend indicates that there will be new devices that until now have never been launched on the market.