“Traditional ATE systems require more expensive redesign on the shop floor as test systems become outdated or unable to meet new requirements, but the open nature of the STS PXI architecture helps us retain our original investment and leverage it. instead of discarding it. It gives us the flexibility to reconfigure and grow our test platforms in parallel with our growing performance needs.” –Glen E. Peer, Integrated Device Technology Inc.

The challenge

Keeping up with the increasing test performance requirements in a rapidly advancing environment is constantly pushing the limits of ATE systems capabilities and consequently accelerating instrument obsolescence and leading to higher test costs.

The solution

Using the open architecture of the Semiconductor Test System (STS) provides the necessary flexibility and the ability to reconfigure and grow our test platforms in parallel with our increasing performance needs; as well as taking advantage of our original investment instead of throwing it away as with traditional ATE systems, which typically require more costly redesign of the test plant as generations of test systems progress. IDT develops a wide variety of mixed-signal semiconductor solutions from low-power to high-performance devices. A world leader in timing devices (clock ICs), IDT offers a wide variety of products for computing, consumer, and communications and networking applications. As the performance of IDT devices increases, it becomes more difficult to keep up in the production test environment.

Traditional ATE systems capable of meeting our high performance measurement requirements are expensive and often include additional capabilities that are not used but add to the cost. Also, in the traditional ATE environment, upgrading a tester to improve its performance typically requires upgrading to the next generation test platform and phasing out the current platform. This is costly because much of the engineering investment made during previous generations may be lost. To combat this, we often build our own solutions in addition to our installed base of test systems. By using different models from almost all ATE vendors, we have become experts in extending the life of these platforms and in controlling costs and improving our measurement capabilities.

Evolution of the test

The evolution of the timing business unit test at IDT is the perfect example of this approach. We started with a high priced commercial ATE system. We quickly realized that this approach was too expensive, so we developed our internal test systems. These systems met our high performance requirements but sacrificed some of the benefits of using a commercial platform such as high parallelism and external support. Therefore we migrated to a hybrid of these two approaches and combined a low cost commercial ATE system with our own performance enhancement system. This methodology worked well, but we were eventually faced with hardware obsolescence that required replacing our chosen ATE and therefore redesigning the system.

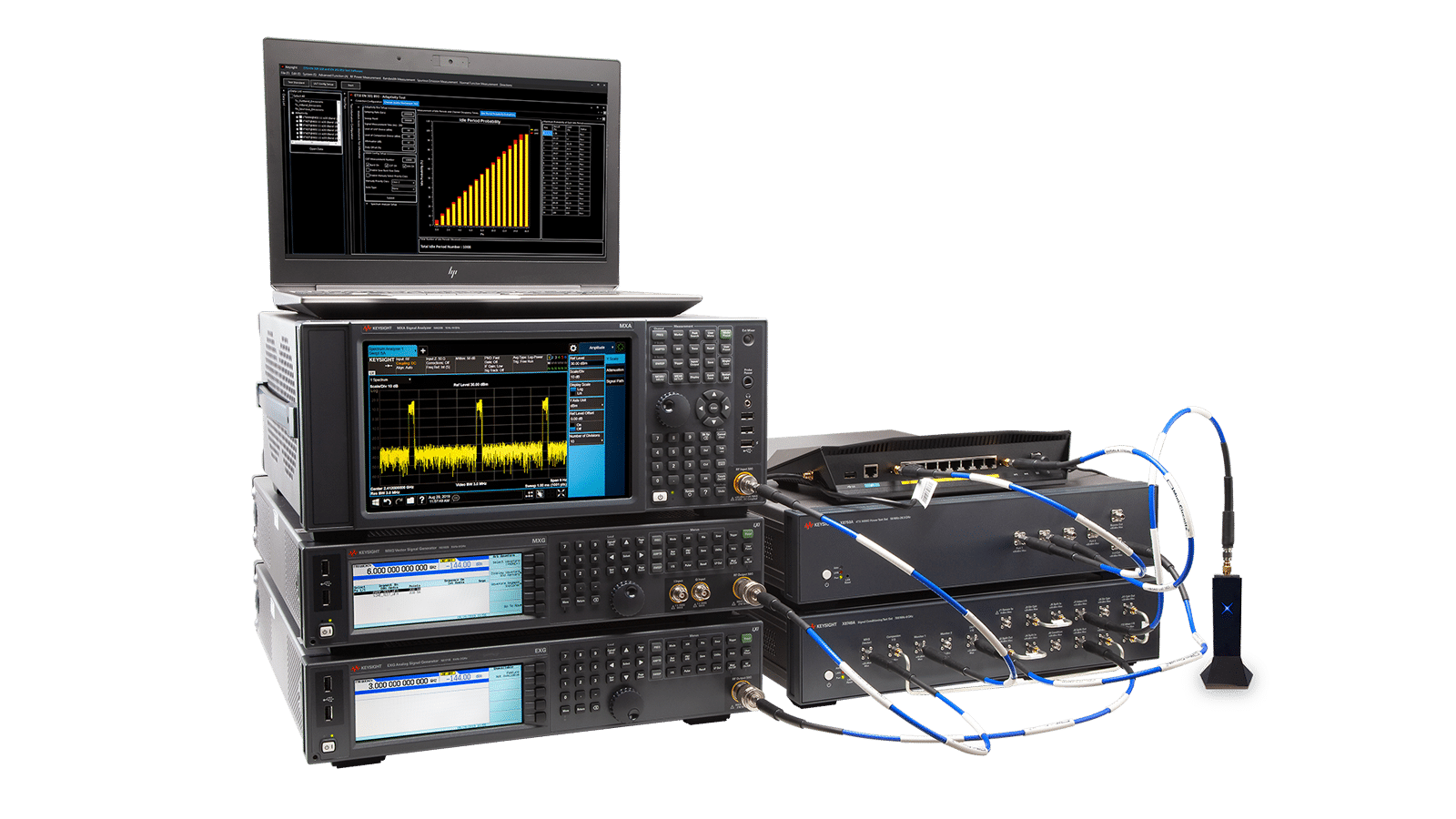

Second, while our hybrid approach was successful from an engineering and performance perspective, it wasn't always production friendly. In general, as new engineering improvements "set" into ATE systems, the systems become more difficult to support in high-volume production. Adding cables, hardware, and sometimes expensive device-under-test cards with electronics to ATE systems increases the potential for potential points of failure in high-volume production environments. The most ideal solution is to create or find a test platform with an open architecture that allows users to leverage their investments from the tester instead of through improvements or reinvestments in high-priced “big-iron” ATE systems. We needed an architecture that wouldn't become obsolete and could be redesigned as technology evolved. The STS provided this architecture. The STS PXI platform is ideal for solving these problems. The system offers multiple PXI chassis within a tester to provide expansion capabilities, so the user can add enhanced test features from within the tester. The open PXI standard gives users the flexibility to select instruments from a variety of vendors according to their needs; rather than the limited options of a single ATE hardware vendor. The STS works well for IDT as the natural extension of our browser evolves.

With this, we can continue to develop high-performance, low-cost test platforms using only the modules and components we need to meet our performance goals. The open architecture of the STS makes this even easier. Over the past year of implementing STS at IDT, we have already upgraded the systems out of the box to meet our changing testing needs. Through careful planning during the initial phase, we ensured that despite these changes, these systems would remain 100% compatible with the initial target solutions. All of our initial investment was preserved when we expanded the testers to allow for broader use across IDT.

The benefits of using an NI solution

We realized several benefits from using NI solutions. First, unlike our previous hybrid approach, we were able to consolidate the test head, which reduced the number of potential points of failure in production, downtime for maintenance and repair, and space requirements. on the plant. We also increased our ability to test a wide variety of devices with the same configuration, since the system has interchangeable interface cards and we can use the same browser configuration for different types of devices. The multisite system allows higher test performance because it is a true parallel test system with high precision performance parameters for hardware optimization. Ultimately, this solution was lower in cost compared to alternative embedded solutions because we had to develop only one instrumentation set and had fewer individual systems to maintain.

grow for the future

The STSs installed in IDT's production test facility run 24/7. We have experienced reductions in test time in the range of 10-25%, improved our measurement ability and accuracy, and freed up our test floor space, making our testers much more production-friendly. By using the STS, we not only increased our test throughput but also reduced the total cost by retiring legacy systems that were difficult to support and maintain. Some of these older systems had expensive power and cooling requirements, but the STSs simply plug into any 110V outlet with no additional installation required. Unit testing costs per hour on these old systems were more than twice the STS.

In addition, our STSs offer high performance measurement features across multiple test sites with true parallel testing capabilities to further reduce testing cost. The STS is a family of scalable test systems with models available using one (STS T1), two (STS T2), and four (STS T4) internal PXI chassis. We designed our STS starting with the T2 model, with upgrades and improvements in mind. The ability to grow our platforms in response to our needs is one of the strongest selling points of these systems. Previously, it was difficult or impossible to share these systems between internal business units, but now we have other teams evaluating our STS. These testing needs are different than what our systems are currently configured with, but with the open architecture of the PXI platform, these users can add skills to the original IDT system definition, which we have already tested in production. Although no ATE platform is ideal for all situations, for the first time we see the possibility of maintaining an ATE platform that can be reconfigured and reused among multiple business units through the simple exchange of interface cards or internal instrumentation modules.

With the STS, we believe we can define one or two system configurations and use these systems in our production test facility to meet the different needs of all businesses in IDT. We have designed our STSs to be able to simply interchange interface cards to allow for various hardware configurations as needed. This ability will greatly simplify our testing operations and further reduce the overall cost of testing. Finally, we can break free from Big-Iron ATE vendors and their hardware obsolescence cycles and determine the best testing strategy based on our own needs. Our current and future investments in test software and hardware are preserved and reusable for the foreseeable future.