No network (data)

We all know the situation: You are on the road and you have to quickly search for something on the Internet. Then comes the bad surprise: there is no coverage! Almost nobody remembers how we satisfied our hunger for knowledge or solved problems before the year 2000, that is, completely disconnected. Only since the beginning of the new millennium have the first mobile network devices been able to receive and send data over the network to an acceptable degree. At first, this only worked with a small amount of data, such as MMS (Multimedia Messaging Service) content. Today, mobile devices are the equivalent of a PC with a cable connection, using the full spectrum of channels and content available on the Internet.

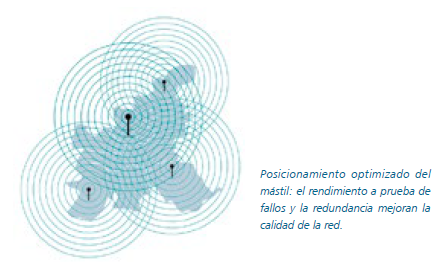

Surfing, chatting, shopping, streaming, social networking – there are hardly any limits to our multimedia desires. And since we quickly get used to any type of comfort, our disappointment is disproportionate when we have to do without it, even temporarily. This is understandable: after all, we are ready to spend quite a bit of money on our mobile “freedom”. Blind spots and distorted voices were common 10-15 years ago, but are rare now. This is also due to the optimized positioning of the transmission towers.

The network is only as reliable as its components

The specifications of the hardware components are decisive when it comes to enjoying a stable network. Components can't be too expensive when looking for a tidy return on investment. Likewise, they cannot be too cheap because then the issue of network failures appears more frequently. Unexpected maintenance and service work must be carried out quickly, otherwise another factor would increase costs and reduce the return on investment. In addition, the network provider is always faced with the question of the period of time for which he must specify the components.

From the year 2000, when the GSM standard with 2G was introduced, until the launch of 4G networks in 2011, a continuous development of the mobile network could be observed. The implementation of 5G, successor to 4G, is currently spreading. Even within a generation there are stages of evolution – for example, from GPRS to EDGE or from UMTS to HSDPA. Transmission speeds have always multiplied. With the introduction of the 4G network, also known as LTE (Long Term Evolution), a transmission speed of around 300 Mbps was reached. The first stage of 4G evolution – LTE-A (Advanced) or even LTE+ – appeared in 2014, and was able to boast transmission speeds of more than triple that of the original LTE network. This makes it a real challenge to predict the lifetime of the components through the generations and evolutions of the network. We can definitely assume that the components will be used for 20 years. Those who want to be completely safe often choose metal connectors, since metal gives a sense of superficial value. We often overlook the fact that plastic connectors are highly suitable for outdoor use. They can even provide significant added value (image 3).

nothing can fall

The components up on the mast have to withstand sun, wind and moisture – sometimes even sand and snow storms. These extreme conditions can release forces of such intensity that the mast and connected components begin to vibrate. Storms can also cause sudden impacts that break fasteners and destroy parts of the system. To avoid this, the applications are recreated in the laboratory and different vibrations are applied. DIN EN 60068 (environmental influences) describes, among other things, continuous sinusoidal vibrations as well as alternating shock vibrations. Forces are released that are far greater than that of gravity. This test should uncover possible weak points, because breaks or cracks in housing parts, faulty locking, or even electrical phenomena such as false contacts or resistance increases can lead to premature failure. The force is equal to the mass times the acceleration, which for a connector means: the greater its own mass and the charge of the connected cable, the more stable the interface design has to be. Thinking like this, the product designer could quickly tend to overengineer. However, if the application is sufficiently defined by the customer, the supplier and the customer can together select the appropriate product for the application. A product that is favorable both in technical and commercial terms.

Connectivity – Security – Speed

The installer is overworked, especially when it comes to installing devices. If you are working on a mast at dizzying heights, personal protective equipment is of particular importance. Added to this are the tools and, last but not least, the devices themselves. The longer the connection to the mast, the more the necessary tools will weigh. Pluggable interfaces – especially made of plastic – help the installer to reduce the weight load. If a device has default pluggable interfaces – eg for power and data – the device does not need to be opened up again on the mast to run the cables, reducing the risk of damage to the power electronics. Once the device is connected, pre-assembled cable assemblies can be conveniently placed and connected to the device in the cable paths of the mast.

Summary

Whether on the coast, in the mountains or in the desert, the connectors in the PRC range are designed for high performance with minimal space requirements. Robust plastics and reliable connection technology contribute to the safe and long-lasting operation of telecommunication systems. Extensive approvals and a continuously growing product range facilitate use in many other industrial areas, including outdoor communication applications. The system operator can choose between pre-assembled device connectors that are manufactured to their specifications and individual components that they can assemble to their own needs.