Primary batteries play a very important role in Internet of Things (IoT) applications. Designed for long life, they have a high power capacity, and are often used in applications where mains power supply is impossible or impractical. Such as smart meters or asset tracking devices (merchandise or animals), vehicle parking availability, environmental monitoring or health devices. Battery life is key to maximizing the total cost of ownership (TCO) of an application. It is directly related to the level and duration of the stress inflicted on the battery by the app, and is therefore specific to any given project. If the “when” and “what” are not well defined, and are not taken into account by the battery manufacturer, maintaining and replacing discharged batteries can drastically increase operating costs (OPEX), and return on energy. the investment (ROI) of the application for its end user. Therefore, understanding the factors that affect battery life is vitally important for an IoT device designer to manage and optimize product performance. So let's take a look at the various parameters that need to be taken into account.

What influences battery runtime?

The amount of energy a battery can hold (energy storage), also called “capacity,” is measured in ampere hours (Ah). The capacity of the battery will determine its average run time (operating time), and will help predict the end of battery life. The nominal capacity of the battery is calculated for a specific current or current range called “nominal”. The average operating time of a battery for a particular application is considered to be determined by the capacity indicated on the battery's data sheet for its rated current range, divided by the draw (amps) required by the application. For example, an IoT device consumes 1 mA, and has a 1200 mAh battery; the operating time is equal to the capacity divided by the consumption: 1200 mAh / 1 mA = 1200h. A common mistake is to look at the nominal capacity of the battery, without checking if the average current consumed by the application corresponds to the nominal current range in the data sheet. Note that capacity alone is not enough to assess battery life. The cycle of a battery depends on several factors:

- The type of battery and electrochemistry.

- Operating temperature affecting electrochemical efficiency

- The discharge rate, which depends on the power needs of the application and the intensity, duration and frequency of the pulse.

- The voltage range of the device (maximum, nominal, and drop-out voltage): if the voltage falls below the drop-out voltage (especially at the end of battery life, or when passivation is significant), the device will shut down. you need to reboot, which will consume additional power. On the other hand, it might provide some major inconvenience for the app like data loss and might even cause its premature termination.

- The leakage currents of the various components of the device, which consume power from the battery.

- Battery storage (storage conditions and duration, before the battery is integrated into the device)

- Device storage (storage conditions and duration, once the battery has been integrated into the device)

How do we calculate battery life?

Calculating battery life for a given application is a difficult mission, requiring an Application Engineer to perform. From Saft we work to serve as a bridge between the client and the engineering teams, our role is to analyze the operational profile of the applications, and the battery requirements to recommend the best durable solution. We also offer technical support to application designers, and share our experience on the best way to optimize your applications. Our 100 years of experience, and millions of batteries deployed in the industry, have enabled us to develop calculation tools based on statistics and historical data, for the two main chemistries used in our primary IoT battery ranges: Lithium Manganese Dioxide ( Li-MnO2 – LM/M ranges) and lithium-thionyl chloride (Li-SOCl2 – LS, LSH and LSP ranges). These tools will allow us to explore, and sometimes challenge, device parameters and constraints to recommend the best possible battery option, and thus calculate the expected battery life for the specific device.

Exploring the environmental conditions of the application

Knowing the temperature conditions of the IoT device during storage, and once it has been deployed, whether indoors or outdoors or both, or in temperate or hot countries, will allow us to determine the temperature profile of the application, and estimate the loss of energy linked to self-discharge and the risk of passivation (leading to a possible voltage drop). Self-discharge is a phenomenon in batteries whereby chemical reactions within the cells reduce the energy stored in the battery, without any connection between the electrodes and an external circuit. Self-discharge can be very complex to model, and depends on several parameters, such as peak current, consumption profile, temperature, cell age, etc. There are two self-discharge phenomena to consider when calculating battery life: self-discharge in storage, and self-discharge in use. The storage period of a battery can be significant, from the time it is manufactured, to the time it is integrated into the IoT device, and to the actual operation of the application.

Self-discharge tends to occur faster at high temperatures. Conversely, low temperatures tend to reduce the self-discharge rate, and preserve the initial energy stored in the battery. In our simulations, we will consider every step of device storage, right up to the device being put into service, to make sure our estimates are as close to reality as possible. As explained above, knowing the temperatures the device is exposed to in normal operating mode is equally important in determining self-discharge in use. Indeed, a low temperature can protect the battery from self-discharge, but the electrochemical and diffusion reactions are slowed down, and the viscosity of the electrolyte is higher, which makes the battery less capable of providing energy and can cause a tension fall. And with the application in constant power, as the impedance increases, the voltage drops, which in turn uses more current, impacting the capacity of the battery. On the contrary, when self-discharge occurs in warm temperatures, some lithium-based cells develop an electrochemical phenomenon called passivation, which protects the cell from discharging itself. But passivation can cause voltage drops (transient or permanent). Knowing the temperature profile is very important in determining a battery's voltage response, as voltage readings drop as temperatures drop.

In addition, the temperature profile will allow application engineers to assess the risk related to passivation (leading to voltage drop or delay during pulses), for batteries with liquid cathodes, such as lithium thionyl chloride batteries. . The passivation phenomenon is greater when the temperature exceeds 30°C. Therefore, we must accurately assess the time the battery spends in hot or cold temperatures, in storage or in use, to determine self-discharge and risk of passivation.

Explore the application's operational profile and power requirements

As we said before, the discharge speed of a battery depends on the energy consumption (or current consumption) of the application, and the intensity of the pulse, duration and frequency. We need to identify the functions that consume the most energy and that will affect the autonomy of the device without forgetting the sleep mode, the consumption in standby mode, and the consumption and leakage current of the various electronic components of the application. These are what have the greatest impact on battery life span. We will need to know the drain of the pulse, in other words, we will need to know the pulse levels, duration and frequency of all the components of the system. All this information will give us the necessary energy during all stages of the device's useful life (storage and operation).

We will study this information taking into account the expected life of the device, so that we can offer recommendations on how to optimize the design and how to select the right battery to achieve the desired useful life. Tension is also very important. We will need to know the maximum, nominal, and cut-off voltage for the application for several reasons: • As the battery ages, the voltage tends to fluctuate. We need to ensure that the selected battery can maintain a voltage higher than the cut-off voltage of the application throughout the life of the device, and across the entire temperature range expected for use. • If the voltage drops below the cutoff voltage, especially with a high pulse, or when passivation is significant, the device must be reset, which will consume power. This could provide a major inconvenience for the application, and could even cause premature end of life. • Depending on the minimum and maximum voltage, we may recommend the use of several cells in a series in the battery, thus offering a longer lifespan. For example, if the minimum voltage of the device is 3 V, and the maximum voltage is 7.2 V, we can use a combination of two cells in a series, which would allow the cut-off voltage to drop to 1.5 V/cell. The devices would have to allow for the space, although there would be a double advantage: it increases the voltage of the battery, and it offers a longer useful life of the device.

- Another solution is to add a supercapacitor or lithium hybrid capacitor in parallel to a thionyl chloride cell, to improve voltage response, like our range of LSP batteries.

- FYI: If you lower the application cutoff voltage, you'll have a wider choice of battery technologies, and you may be able to get rid of otherwise necessary power-hungry components like supercapacitors. One last question to ask yourself is whether the battery sought for the project is the main battery of the application, or a backup battery. The latter will remain in standby mode for a long time, until they are suddenly needed, in which case the battery must have the ability to react quickly. Obviously, this will also affect its longevity.

Exploring the battery technology itself

Now that we've learned the device's requirements and limitations, we'll be able to recommend the right battery for your project. Last but not least step in the life calculation process is the choice of chemistry that affects battery longevity. Li-SOCl2 chemistry, for example, has an exceptional reputation for reliability and long life. It also shows a higher energy density, which you can recover in up to 20 years. Another chemistry, such as lithium-manganese dioxide (Li-MnO2), is particularly suited to high-pulse applications, with low cut-off voltage, and offers a good balance between energy and power. Together with energy efficient electronic components, they can offer up to 20 years of service.

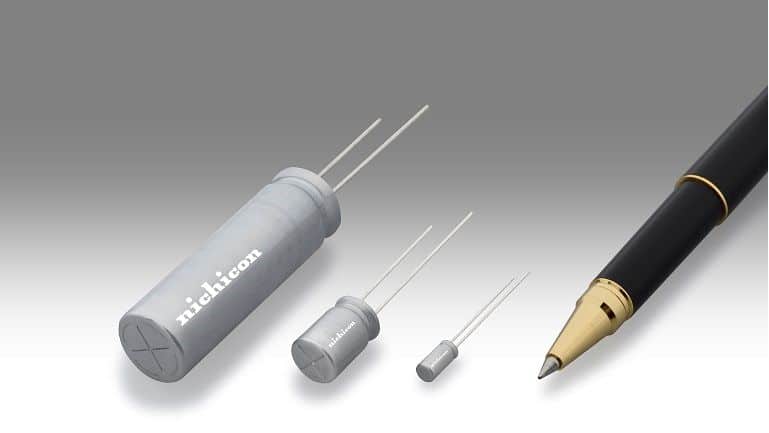

The cell construction also has a feature: a coiled technology that offers plenty of power for high pulse applications (up to 4A), while a coil construction will offer low self-discharge, and high capacity over time, but without increase the current to a few mA, or a few dozen mA. Finally, for very long term discharge applications (10-20 years), we might recommend the use of a LiSOCl2 coil cell combination with a capacitor, such as our LSP range. The capacitor is designed to help the battery maintain the perfect voltage during the pulse, throughout the life of the application and in any temperature condition. The ability to maintain the pulse of the capacitor will avoid the passivation effect by storing electrical energy, and releasing it when necessary. Battery capacity will be slightly affected by the capacitor, but the pulse drain produced by the cell will be reduced, allowing for longer battery life.

Juggling requirements and constraints to get the most out of your device's battery life

In the end, our goal is to recommend the correct battery chemistry and technology, so that the device can function properly throughout its life, making full use of the battery until the end of its life. Experience is key in this process. since any wrong reading of passivation or self-discharge, or any abuse that a battery is subjected to in conditions for which it was never designed could lead to premature failure: the battery is below the cut-off voltage and cannot be restart. It then sits half charged, a waste of electrochemicals, time, and money, despite the broader financial consequences that could jeopardize the project. If you have any questions about this item or would like to contact one of our experts for a battery recommendation or lifetime estimate, please feel free to email us at contact@saftbatteries.com. We will be happy to help!