The new flagship of quick pallet change technology

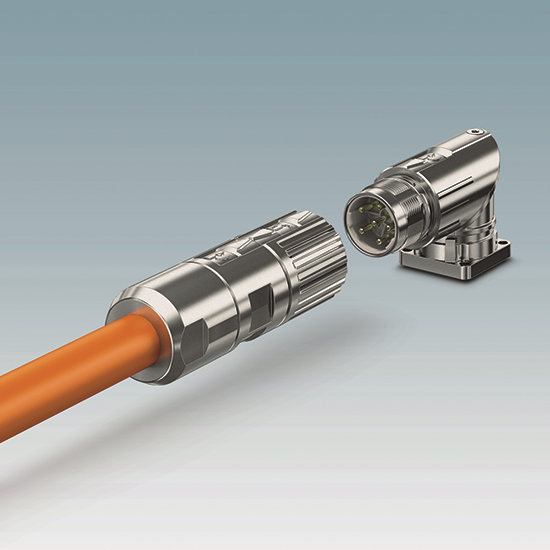

SCHUNK introduces two high-quality quick-change pallet modules with unique features on the market: the VERO-S NSE3 138 quick-change pallet module and the VERO-S NSE-T3 138 module for turrets. Its most prominent feature is an optional spring-loaded taper seal that automatically closes the module change interface as soon as the clamping piston is raised. In combination with the integrated blow-off function, the quick lock prevents chips or dirt from getting into the interface. This feature locks the last walkway of the sealed modules completely without the need to change the height.

Even greater deployment force and rigidity

SCHUNK has once again strengthened the performance characteristics of the VERO-S NSE3 138 compared to its previous best sellers. An incredible pulling force of 8.000 N, or 28.000 N with the turbo function activated, as well as a greater dimensional stability of the body of the module positively affect the rigidity of the clamping solutions. In addition, even the largest transverse forces and moments can be reliably absorbed when workpieces are held at the base and machined at height, for example. On high-quality modules, a small taper with a repeatability of less than 0,005mm takes care of clamping and positioning, ensuring maximum precision even in the most demanding applications. Due to the conical fit, the clamping pistons can also be attached to the modules eccentrically, greatly facilitating this process. The form-fitting, self-locking clamping is carried out by spring force without the need for an external power supply. Work pieces remain securely clamped in the event of a sudden loss of pressure in the pneumatic system. A pneumatic system pressure of 6 bar is sufficient to open the clamping modules.

comfortable monitoring

To achieve maximum process reliability, the system incorporates dynamic pressure checking of both the “open” and “closed” positions of the clamping pistons as standard. Optionally, a position sensor can be used, which additionally detects a locking process without pins. Depending on the thread diameter of the clamping bolts, the magnitude of the clamping forces will be 35.000 N (M10), 50.000 N (M12) or 75.000 N (M16). All components such as the base housing, clamping pins and pistons are made of hardened stainless steel, making them absolutely corrosion resistant and extremely durable. The special support zones facilitate cleaning and guarantee a perfectly flat contact surface for clamping devices and work pieces. The new high-quality modules are fully compatible with the previous VERO-S modular system, which currently has more than 1.000 possible combinations for highly efficient workpiece clamping.