There is often a reluctance to go for a bespoke interconnect for a design until it becomes clear that there is hardly any alternative. This reluctance is due in large part to the widely held view that custom connectors are expensive, that the customization process would add unacceptable delays to the project, and finally that it is risky to rely on just one manufacturer. These three widespread impressions have little or no foundation at all, according to the French connector manufacturer Nicomatic.

Custom design is too expensive

It is easy to compare the design budget with a custom connector and with a standard solution to conclude that the first one is more expensive, but the real cost of the complete solution and its integration in the system should also be calculated, including “hidden costs”, so that the comparison is accurate.

A typical example was a Nicomatic customer trying to connect a PCB inside a box to a breadboard connector on the other side of the box. The customer used a standard connector to design a system with complex wiring between the two connectors and added a cap to provide EMI protection. Using a standard connector increased complexity by requiring the integration of multiple pins, taking up more space on the board, and adding cabling and cap cost. Towards the end of the project, the customer requested support and the solution came in the form of a custom one-pin connector. This made it possible to free up about 30% of the space on the board for additional functions. There was also no need for wiring and all complex operations were avoided. In addition, Nicomatic's custom connector incorporated an EMI back cover.

Space and weight are two primary factors in some markets, especially aerospace. You have to take into account the cost per kilogram; For example, fuel consumption is important in civil and defense applications, especially in space launches where each added gram requires more fuel. Miniaturized custom interconnections allow having more functions in the same space, improving technical performance and having a product with higher specifications.

Projects can also have hidden times. A single supplier can not only design a customized interconnection but also allows access to a complete solution, even if it is made up of connectors from different brands. Managing a single supplier saves valuable project management hours, streamlines processes, simplifies communication, and should also reduce lead times.

Collaboration from an early design phase saves costs. Some manufacturers will send an engineer to the customer's site to work with the customer's team, a good way to get an optimal solution that meets the customer's technical specifications and budget.

If a customer needs to replace obsolete components, it is less expensive to redesign an existing solution than a complete system. This can also be an opportunity to improve overall system performance and integration within the same overall dimensions.

Customization takes too long and is too complex

How long does it take to produce a custom connector from scratch? This depends, of course, on whether the specifications have been clearly defined, as well as the manufacturer chosen. Once you decide on the tailor-made solution, it is necessary to clearly agree on the project deadlines with the supplier. Nicomatic received 1000 such requests in 2020 and responded to 90% of them in less than 5 days despite the difficulties imposed by the pandemic. The average delivery time was 3 to 12 weeks. Design work usually takes 1-2 weeks, while production takes 3-12 weeks depending on complexity. For example, it's 3 weeks for something like a cable or a small bespoke solution and 12 weeks for a fully bespoke connector. This speed is made possible by the ability to machine parts quickly and develop a mold simultaneously. Machined parts are used in prototypes and production moves to molded parts when many units are needed.

A single vendor solution is a bad idea

A unique solution makes your design exclusive and keeps you ahead of your competitors. Although it is tempting to think of having more than one supplier as protection against supply chain problems, engineers are increasingly turning to a single solution that makes a design unique and provides a great technological advantage to stay ahead of the game. competitive markets. However, innovative ideas need the right manufacturer to make them come true.

Choose a reliable connector supplier with advanced technical knowledge, experience in custom solutions, multiple production sites, and sound financial health. Their production process should be integrated and the manufacturer should be certified to EN9100 or the corresponding standards and, very importantly, they must be committed throughout the duration of all their projects; No sudden obsolescence.

Conclusion

Recognition at an early stage that a bespoke design may be required, coupled with an open dialogue with an experienced and trusted manufacturer, saves cost, time and hassle. The co-design of a solution is more and more frequent and serves to improve the competitive profile, although for this it is essential to have a manufacturer with the appropriate technical knowledge.

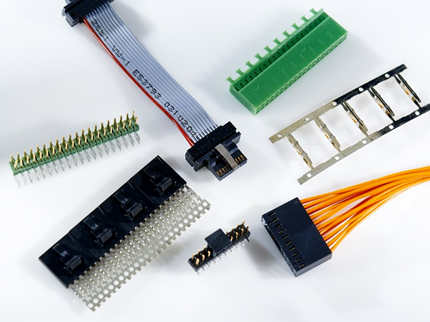

Nicomatic has supplied many thousands of custom connector solutions, from small modifications of their standard connectors to unique custom designs for the aerospace, defense, medical and rail markets. Its tailor-made solutions are delivered within short delivery times and with no minimum order amount.

Phil McDavitt, MD, Nicomatic UK Ltd.