Versatile technologies to transfer high currents to the PCB

The connection technologies of future generations of equipment have to provide more performance in less space and guarantee safe and comfortable operation, even in installations with limited space. The new connection solutions from Phoenix Contact make these conditions a reality. Manufacturers of equipment such as power supplies, regulators, controllers, and I/O systems typically manufacture products for use internationally. Not only do they have to follow international standards and safety regulations such as those of the International Electrotechnical Commission (IEC) or Underwriters Laboratories (UL), but they also have to build their devices with different user behaviors in mind. While system builders and installers in the United States prefer screw connections, European users have been using quick-connect technologies such as spring-loaded and push-in connections for decades. This difference has its origin in the geographical and historical characteristics of the local industries. The importance of properties such as intuitive operation, design, connection time, material quality and costs are weighted differently depending on the region. These criteria also affect the functionality of the equipment.

Continuously developing connection technology

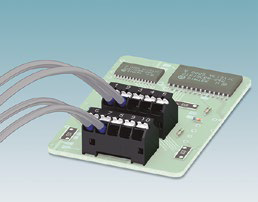

The choice of connection technology in the initial stages, with the necessary help from its manufacturer, has a decisive influence on the later versatility of use offered by a device. This is why the connection technology requires continuous development. Transmitting high currents and power, while offering simple and comfortable operation, is and will continue to be important for future application areas. Not all connection technologies are suitable for demanding high current applications such as frequency inverters. In addition to the required cable size, the PCB layout and equipment design are the factors that primarily determine the choice of connection technology. For applications with cable sections of more than 35mm2, Phoenix Contact offers a variety of solutions ideal for multiple applications, both industrial and infrastructure. This product range ranges from the SPT 35 PCB terminal block with push-in spring connection to the PC 35 plug-in connector and from the MKDSP 50/95 screw connection terminal block, suitable for wave soldering, to the terminal block TW 50/95 cable gland.

proven security

The power connection from Phoenix Contact is perfectly tailored to the user's requirements in terms of operating convenience. It also meets safety requirements for material and processing quality. The electrical suitability of the components is demonstrated by resistance measurements and surge tests performed. In addition, the reliability of the contact is also extensively tested, as this factor plays an important role in choosing fast connection technologies. Since the cable cross-sections and the potential mechanical forces that can occur increase with the electrical power transmitted, power connections are subject to high safety requirements. Depending on the conductor cross section, properly wired connections in accordance with DIN EN 60947-1 can have to withstand enormous tensile forces of several hundred Newtons. Standardized cable bending and tensile tests provide manufacturers and users with the peace of mind that even simple-to-operate terminal blocks and connectors, such as the TW95, guarantee solid and reliable long-term contact. Forecast The trend towards miniaturization in components for power electronics translates into less installation space available for frequency inverters, drives, actuators and similar devices. Cable connections become smaller and more difficult to access as equipment gets smaller. While many connection technologies today offer flexible solutions for the smallest cable cross-sections, fast connections for large cross-sections of 35 mm2 are becoming increasingly important. Phoenix Contact offers ideal solutions for this area, covering a wide range of applications.