The dream of many is to be taken from point A to point B without care on their own – a dream that comes true in KITT, “the fantastic vehicle”, or the vehicles in the movie “The Fifth Element”. Modern vehicles are getting closer to these visions of the future and multiple sensor technologies play one of the most essential roles here. One of the most promising is lidar.

Like radar, lidar is a detection and ranging (DAR) procedure. Both use exactly the same form of echolocation as bats. They emit ultrasound and detect where objects or prey are based on which way they bounce. While radar uses radio waves, lidar uses light waves.

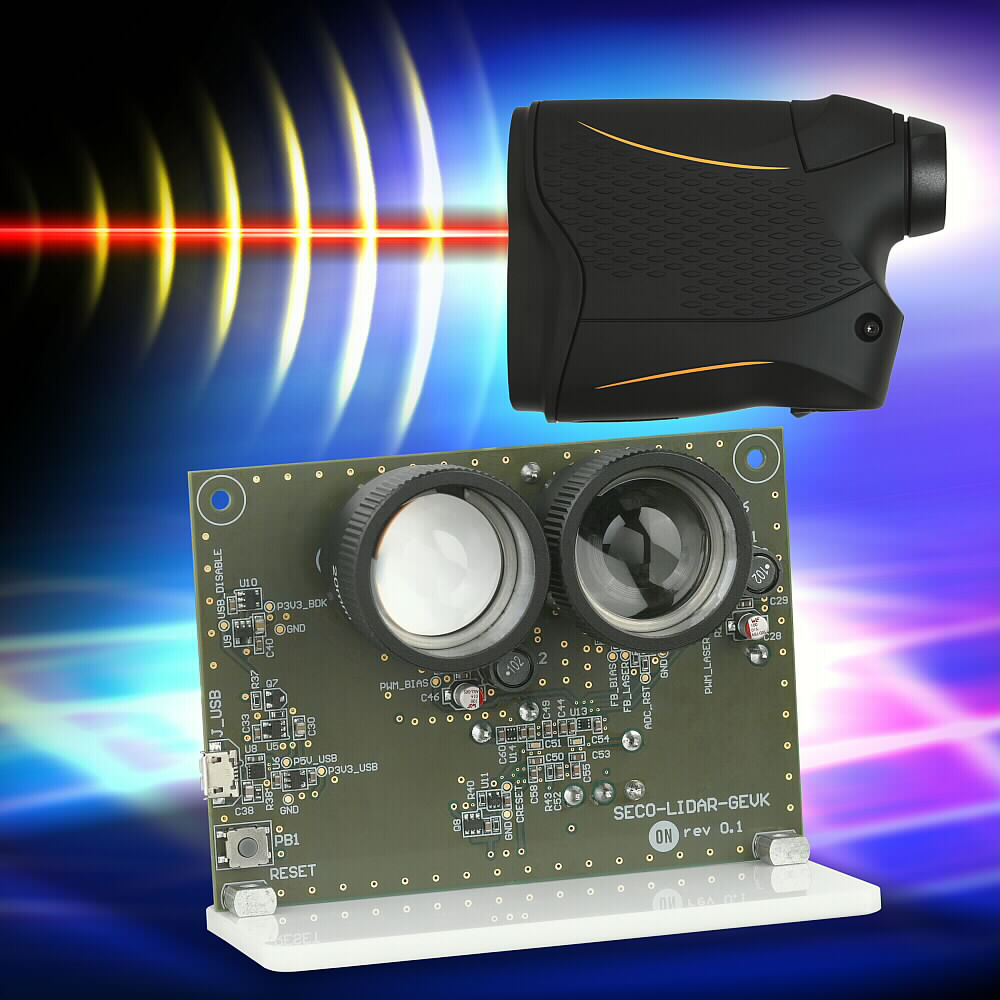

Lidar sensors use a pulsed laser diode that sends out a pulse of light. If it is reflected by an obstacle, the sensor will warn you. The time of flight (ToF), which is the time that elapses between the emission and reception of light waves, allows the distance between the sensor and the obstacle to be calculated.

Highly sensitive detectors

The light waves are scattered in many directions depending on the distance and the way of the reflecting object or living being. This is the reason why the longer the range of the detector, the more accurate the image of the environment that is generated will be – since it can capture even more reflections. The present lidar sensors use avalanche photodiode (APD) arrays of 8, 12, or XNUMX diodes. Each diode represents a pixel of the complete image. This means that apart from the size of the matrix, the distance between the diodes (=pixels) is also a factor in the resolution of the sensor. The sensitivity of APDs is also relevant. At best, they should see as few traces of the reflected beam as possible.

The ideal light beam

The length of the light pulses play an essential role in the resolution of the sensor, which is why lidar manufacturers take great care to develop the shortest possible pulse lengths. Today, they measure five ns on average and up to a maximum of ten ns. Another factor is the size of the light beam. Since the laser diode sends out an extremely focused beam of light, it can only measure the distance of a point that is exactly the same size. This is not enough for use in driver assistance systems (ADAS) and much less in autonomous cars. There are multiple solutions to extend the field of view (FOV). Here, the challenge is to see even the smallest faces in a large field of view.

Eye and skin safety

One constraint in lidar development is eye safety. Since laser beams can affect people's retinas, especially when used in traffic applications, it is essential to ensure that they do not cause damage. Skin can also be "attacked" by lasers. The EN 1-3 standard defines multiple classes depending on the hazard to eyes and skin – both wavelength and pulse length are the stars here. We show 1 examples of laser classes: Class 0,25 is for laser radiation that is not hazardous or a closed canopy is used, while Class XNUMX is for laser radiation in the XNUMX perceptible ghost range. at seven hundred nm. With an exposure time of up to XNUMX s, it is not harmful to the eyes. Class four lasers are extremely dangerous to eyes and skin, even if scattered.

Flash lidar – scattered light

One method of spreading the FOV is based on spreading the light beam to cover a larger field of view with a wide beam angle. Known as a "flash lidar," while the light is diffuse in such a case, it is considerably weaker than a focused beam of light. Even so, to achieve improvements in range and resolution, laser diodes with a very high output of 1–2 kW are used.

For applications where only close range object detection is required, Vertical Cavity Surface Emitting Laser Diodes (VCSELs) with a wavelength of 2 to XNUMX nm are ideal. They can be used when developing powerful XNUMXD patterns. For detectors, highly sensitive sensors that can detect even single photons – known as single photon avalanche diodes (SPADs) – may be advantageous. With the aim of increasing the range and coping with the conditions of intense exposure to sunlight, the Fraunhofer Society has developed SPAD CMOS detectors for microelectronic circuits and systems. The SPADs integrate a CMOS process that is certified for the automotive field and has been optimized for optoelectronic applications. This enables extremely fast and highly sensitive avalanche photodiodes to be generated with up to XNUMX momentary amplification, high pulse rates and low noise.

Laser Components offers a flash lidar sensor with SPAD CMOS – the SPAD2L192 is a 192x2 pixel solid state CMOS sensor for flash lidar applications. Measures distances based on the first-photon direct ToF principle. Single photon detectors give extremely high sensitivity and high temporal resolution. The time-to-digital converter with a time resolution of 12 ps and a full scale value of 7 µs leaves a nominal range of XNUMXm and a resolution at a distance of XNUMXcm.

Lidar scanning – mobile specula

To sustain light intensity while covering a larger FOV, scanning lidar technology employs the principle of "scanning" the field with a beam of light. Using moving micromirrors, light is directed onto the FOV to be scanned. Scanning lidar sensors usually use between one and sixteen laser diodes. Edge-emitting lasers (EEL) with a wavelength of XNUMX nm achieve the best results here, while high-power laser diodes with more than XNUMX W reach distances of up to XNUMX m.

Since only a few diodes with partially low power are required, scanning lidar sensors offer good thermal properties. This allows very high pulse rates, protecting the eyes even with a wavelength of XNUMX nm.

The FOV is usually one hundred and forty-five ° on the "y" axis and three and two ° on the "z" axis. In theory, a 5° panoramic scan should be possible with this technology, but in practice there tend to be “blind spots” – the light beam is useless in scanning the surroundings – for this reason, radar and camera solutions sumes give a workaround option for this crack. However, due to their size and weak design, scanning lidar sensors are not suitable for use in automobiles. They have dimensions of about ten.XNUMX x six x ten cm, being too large to, for example, be used in the frame of a lighthouse. Movable specula are also highly sensitive to vibrations, impact, dust, and extreme temperatures found in vehicles.

Suitable diodes are available from Laser Components – the 905DxxUA series includes pulsed laser diodes in multi-junction and easy junction designs with a laser output of up to 101 W and a wavelength of XNUMX nm. Components are completely reliable, offer unusual thermal stability, and feature precise chip alignment in a hermetically sealed package. This makes them ideal for distance measurement and obstacle detection, inspection equipment, laser radar, and many medical applications. Models with the AEC-QXNUMX qualification can also be used in passenger cars.

Si-APDs or Si-APD matrices are recommended for the detectors. Laser Components' SAHA series of Si-APDs are optimized for wavelengths from 1 to 8 nm. Semiconductor material is especially effective here, and pulsed laser diodes emit at these wavelengths as well. In a miniature SMD package, Si-APDs provide high quantum efficiency and therefore high sensitivity and low noise. The SAH12Lxx series dies with 44, 12 or XNUMX high-sensitivity Si-APDs in an LCCXNUMX package with a protective window give exactly the same characteristics. They offer a very low section of forty µm. Also available is a matrix with XNUMX APDs in a fourteen-pin DIL package. In addition to the standard matrix, there are also customized versions with specific APD numbers and sizes.

Solid State Lidar – Semiconductors instead of mechanical components

Solid-state lidar sensors provide a more robust and compact alternative option. They rely on semiconductors instead of mechanical components to direct the beam of light. There are 2 versions: one with MEMS-based specula and the other with optical phased arrays (OPA).

Models with MEMS-based specula employ an array of micromirrors, each with an edge length of a few micrometers. They change between 2 multiple situations thousands and thousands of times per second, moved by electrostatic fields. This type of lidar sensors are used in applications such as scanners of purchase boxes or DLP (digital light processing) projectors, with which it is a proven technology with partially low production costs.

However, in automotive applications, sensors must meet considerably more stringent requirements. For example, they require a larger FOV compared to POS purchase systems or projectors. With a scanning frequency of more than one hundred Hz, existing solutions offer angles of forty°; MEMS systems with higher angles are already under development.

With lidar sensors using OPA arrays, a modulator lets one pulse cover a larger area and alters the phase of the light emitted by each laser diode. The technology is still in the research phase. One variation uses a silicon circuit that is only several square millimeters in size as a substitute for the rotating transmitter and detector unit. To support higher outputs and a longer FOV, tests are being conducted with wavelengths that reach farther into the infrared range than the XNUMX nm conventionally used today. For example, a wavelength of XNUMX nm is not harmful to the eyes, but it could be negatively affected by snow or rain. Here, too, other detectors are required.

Many technologies make science fiction really scientific

Although we are a few years away from achieving autonomous driving as described in sci-fi movies, each assistance system – which can be adaptive cruise control (ACC), emergency brake assist (EBA) or the lane departure alarm (LDW) – is one more step towards achieving the goal. For many of them, lidar is a major component, which must be fully coupled with other technologies such as ultrasonic sensors, cameras and radar solutions – because each technology has its strengths and weaknesses.