Four reasons why integrated current sensors are the ideal solution when control, efficiency and protection are critical

Charles Flatot-Le Bohec, Global Product Manager for Electromobility, LEM

Current sensing is a primary function in a wide variety of electronic devices, such as power supplies, battery management systems, electric motor drives, and renewable energy networks. To be protected and operate efficiently they require current sensing that is accurate and reliable.

However, measuring current comes with challenges such as the power density of the devices and the goal is always to do more with less, such as a smaller PCB size. In this environment marked by space limitations and higher power density, integrated current sensors (ICS) play a vital role.

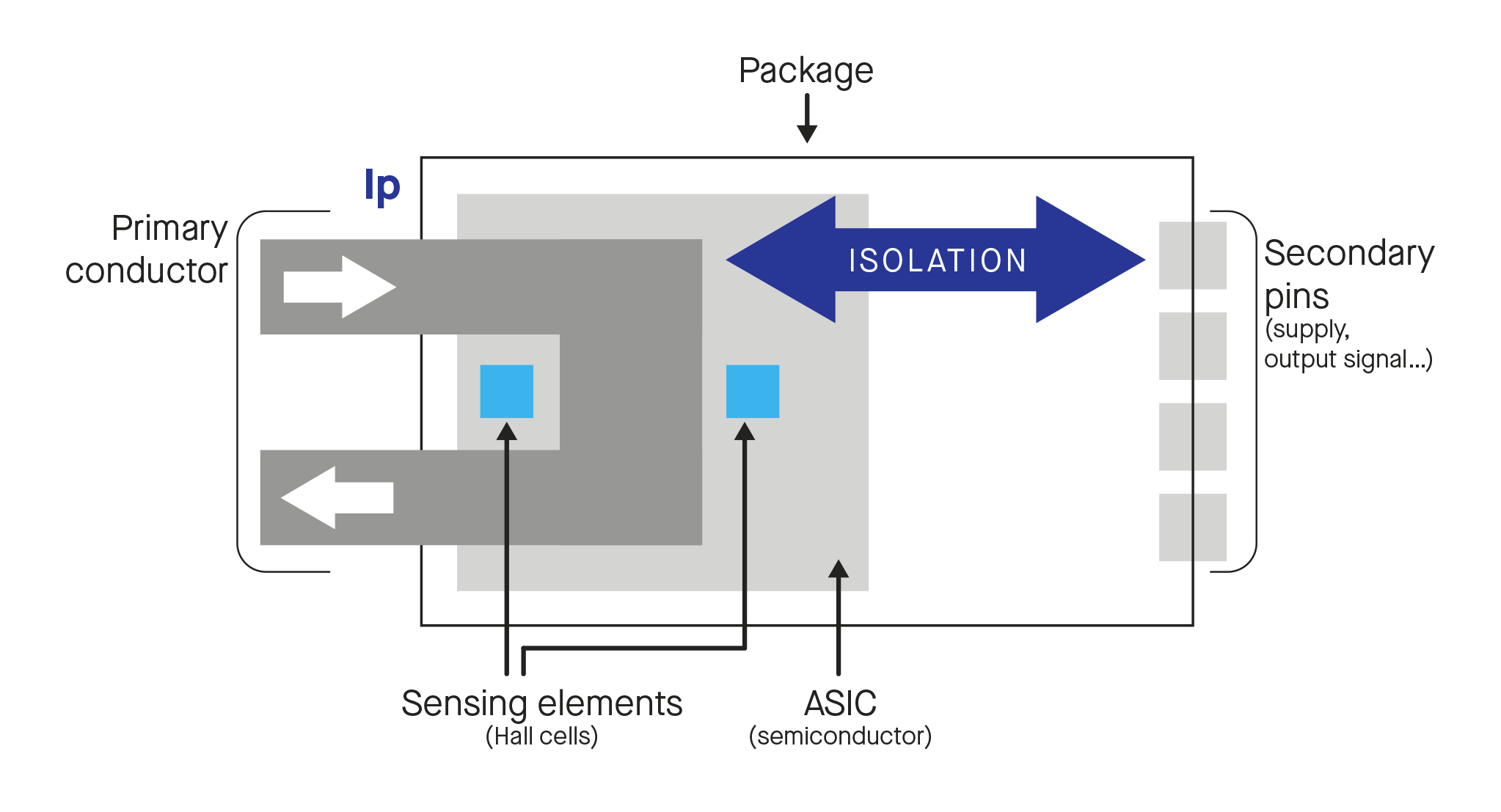

ICS, ideal for various automotive, industrial or residential applications, are current sensors based on the Hall effect that incorporate the current conductor, detection elements, integrated circuits for signal processing, some specialized functions such as fault detection and isolation. , all in the same package.

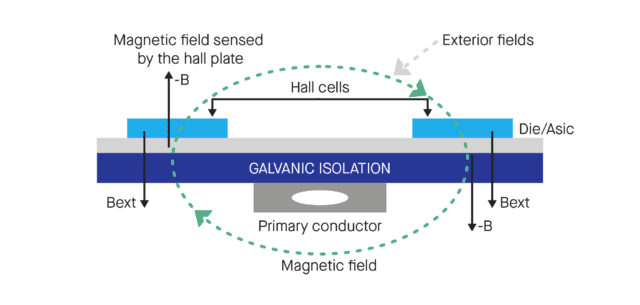

Hall effect detection is a way to obtain contactless measurements in a current-induced magnetic field. The Hall cell is the sensing element that converts a variation in the magnetic field into a variation in its resistance and, when a constant current passes through the Hall cell, it supplies a variation in the output voltage proportional to the magnetic field.

As a leader in electrical measurements for 50 years, LEM continually develops new technologies to meet the changing needs of its customers in the sectors it covers, which is why the company has invested in its own ICS design function and is now in the process development of a complete range of ICS.

Four key benefits explain why LEM believes integrated current sensors are a suitable investment.

Coreless design

Traditional Hall effect current sensors use a ferrite core placed around a current conductor and sensing elements to concentrate the magnetic field. This core also provides protection against unwanted external magnetic fields and noise. The differential measurement makes it possible to eliminate the ferrite core and use two detection elements (Hall cells) that receive the magnetic field to be measured: one with a positive factor and the other negative. The difference between both fields allows you to cancel any other unwanted magnetic field.

The ICS take advantage of the differential measurement to avoid resorting to a ferrite core. Removing the core offers several advantages in embedded applications. For example, the cost of the device is reduced, the power density in the sensing part is mechanically increased (up to 75A in 800V applications for LEM ICS products) and the measurement is not affected by magnetic hysteresis (when applies an external magnetic field to a ferromagnetic material and the atomic dipoles align with it). Finally, frequency and bandwidth are not limited by the inherent saturation of the core magnetic element.

Embedded insulation

Some systems require a certain type of isolation to protect the end user, which means that the user interface must be physically separated from the high voltage network and cannot share the same voltage reference level. An ICS integrates the isolation function inside (galvanic isolation) and outside (air distances and creepage distances) of the device, which means that if there is no physical connection between the primary conductor through which the high voltage current circulates and the secondary circuit with the ASIC (application specific integrated circuit) chip and the secondary pins. These two parts only communicate through the magnetic field generated by the current that circulates.

The production of the ICS ASIC is based on the CMOS semiconductor manufacturing process that allows certain functions to be integrated into the component without adding any hardware. For example, all the analog and digital elements necessary to detect, amplify and process the proportional voltage signal are manufactured on a single chip with semiconductor materials, thus ensuring their low levels of power consumption and dissipation.

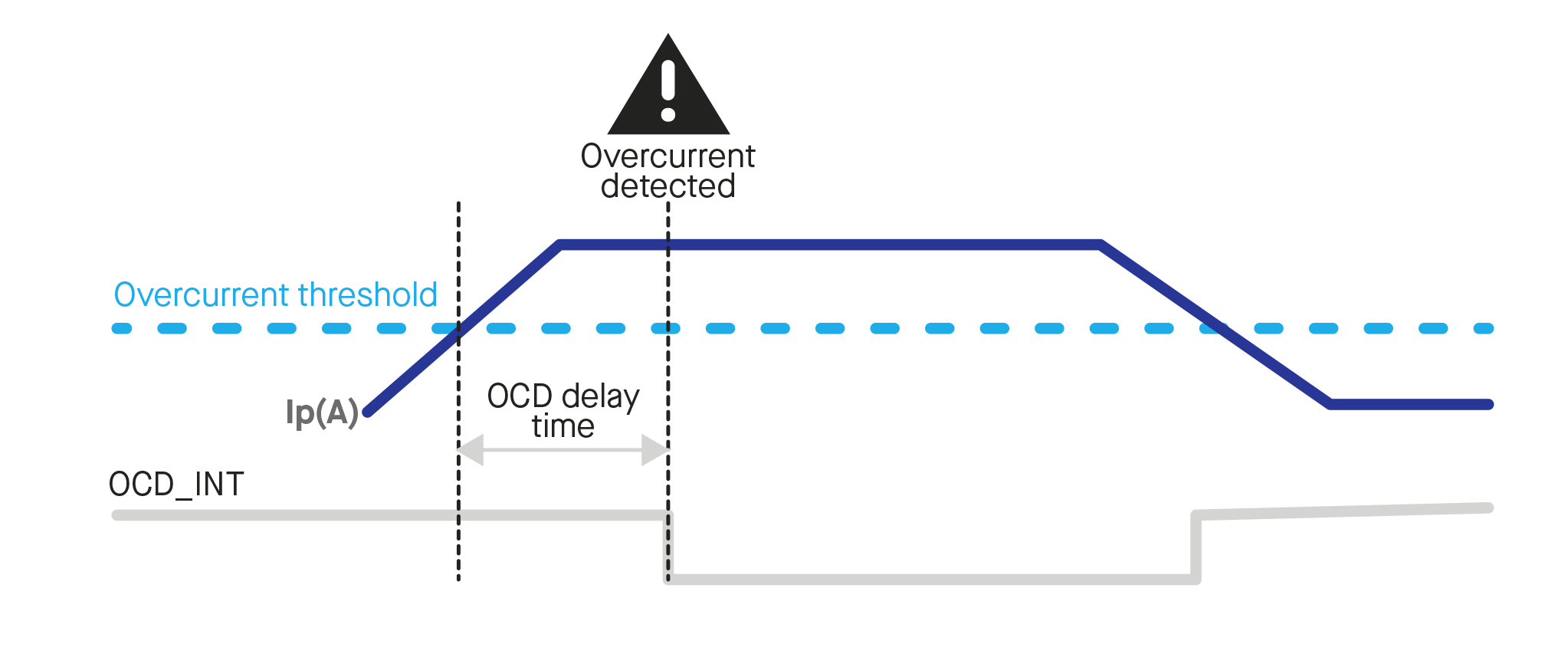

Over-current detection (OCD) is also an important factor. With internal OCD, when the current exceeds a threshold it internally activates a signal and sends it to a fault pin. This allows the application microcontroller to receive the alert information with minimal time delay. Otherwise, the action would have to be performed internally and based on the current level sent by the sensor, so it would take much longer.

Compensation and other integrated functions

In terms of stress and temperature compensation, if the ASIC is subjected to mechanical stress in the package, it can lead to sensitivity drift (the same can happen with temperature variations from -40°C to +125°C). °C). The ASIC's internal sensors compensate for this drift to ensure linear and accurate sensitivity under a wide range of conditions. In a design based on discrete components, the shunt temperature varies greatly depending on the resistive losses, hence requiring another step in the microcontroller design process for the compensation to be exact. In contrast, the ICS-based solution simply has to be plugged in.

The output voltage is usually proportional to the measured current, but there are two possible reference voltages. In proportional mode, the output voltage (Vout) is expressed as a percentage of the supply voltage (Vcc) and requires a stable voltage source. In fixed (non-proportional) mode, Vout is compared to an external reference voltage (Vref). The proportional signal is in this case Vout minus Vref, but when the current to be measured is 0A, Vout = Vref. In other words, the reference voltage is determining the output voltage at rest (zero current mode).

LEM has developed two families of ICS: the HMSR and GO series. LEM's HMSR and GO-SMS ICS incorporate internal and external OCD to protect the system as much as possible and also have voltage and fixed outputs to choose from depending on the characteristics of the system. LEM's HMSR series provides greater immunity with its integrated core, while the GO series takes full advantage of differential measurements to offer all the performance of a Hall effect current sensor in an SOIC8 or 16 SOIC (outline integrated circuit) format. for surface mounting. For example, GO-SMS can guarantee basic insulation of up to 2088V and reinforced insulation of 1041V (DC mode or maximum operating voltage) in compliance with IEC 62368-1.

Plug-and-play design

In summary, integrated current sensors allow designers to realize the current sensing function through a plug-and-play approach that overcomes virtually all of your challenges with a single component. The total mechanical integration and very low power losses ensure that the ICS takes up as little space as possible and does not present any thermal difficulties.

By design, non-contact measurement with galvanic isolation, together with standard air clearances and creepage distances, make ICS suitable for high voltage applications and can offer a design strategy with reinforced insulation. Smaller packages with less insulation and fewer features can lower the cost to be competitive when isolation is not necessary (< 60VDC). This flexibility in product definition allows LEM ICS to be appropriate for a variety of products, whether in cost-optimized applications or high-end isolated designs.

The performance of the ICS is not compromised because all signal processing is carried out in the package with semiconductor elements. This allows specific system protection mechanisms to be integrated, such as rapid overcurrent detection. Depending on the system architecture and the chosen design, the output voltage proportional to the current can take as a reference the supply voltage (Vcc) or an external one (Vref).

It is clear, then, that integrated current sensors are ideal in a wide variety of applications that require control, efficiency and protection. In particular, LEM's latest ICS are particularly suitable for applications with limited space and high power density.

LEM plans to develop more ICS products that meet the specific needs of its customers. In a next phase it will present the HMSR DA, the first ICS with sigma delta digital output.