Author Edgar Schafer, Field Application Engineer Automotive Business Unit (ABU) of Rutronik

An increasing number of vehicles are equipped with 12 and 48 V electrical systems to be able to operate with “small” and “large” consumer devices in an efficient manner. In order to ensure the safety of the circuitry, Vishay has developed a high performance, low loss intelligent Electronic Fuse (eFuse) card.

Due to the integration of the 48V electrical system and the 48V standard in light hybrid vehicles, the protection against overloads or short circuits also has to be re-evaluated because a greater distance between the 48V relay contacts is required ( supply voltage) instead of 12 V, with the mission of extinguishing the voltaic arc that occurs when the protection relay is activated. This results in a delayed shutdown and faster contact wear.

Therefore, conventional 48V relays are replaced by eFuses, which are based on semiconductors and do not have contacts whose wear is primarily related to switching devices. Thus, the useful life is increased. In addition, thanks to its faster switching behavior, diagnostic capabilities and lower tolerances, significantly higher safety is guaranteed.

Vishay has developed an intelligent eFuse that is designed to continuously switch loads from up to 200 A at 48 V. The maximum current can be set between 1 and 200 A. If the defined value is exceeded, the electronic fuse switches to 1 μs. Unlike a conventional fuse, the eFuse can be Reiniciar, which means that it no longer needs to be replaced after activation.

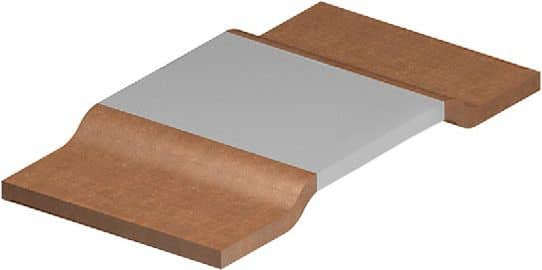

Figure 1. Vishay's SQJQ160E compact MOSFETs enable efficient operation of the smart eFuse, due to their on-resistance power supply extremely low drainage.

Even with a switching capacity of 200 A, its power loss is below 14W. In other words, passive cooling is sufficient with an ambient temperature of up to 100 °C. Active cooling is only required at higher temperatures.

Two Phase Ignition Behavior

The intelligent eFuse operates with a two-stage ignition process. First, a short circuit test. During this test, a 13 µs pulse is applied across a series connected resistor. If the output voltage is 10 percent below the input voltage, a short circuit is assumed and the electronic fuse is turned off again. However, if the output voltage is 10 percent higher than the input voltage, the second phase, also known as phase two, takes place. preload.

To prevent excessive current caused by capacitive components on the consumer devices side when the eFuse is activated, they are composed

Before they are precharged by a series resistor until the output voltage corresponds to 85 percent of the input voltage.

Once this value is reached, the eFuse turns off.

Figure 2. Wi-Fi is a market with billions of devices and economic value currently estimated at $3,3 trillion. (Source: Wi-Fi Alliance).

Main components of the smart eFuse

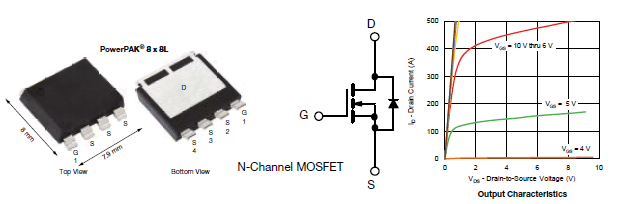

At the core of the intelligent eFuse are twenty MOSFETs SQJQ160E of Vishay N-channel, which are based on the latest technology TrenchFET Gen-IV, with an RDSon of only 0,8mΩ. As bi-directional MOSFETs, they prevent reverse current flow when the electronic fuse blows. Presented in a compact package PowerPAK-8x8L and operates reliably in the temperature range from -55 to +175 °C.

Minimal power loss is ensured by the high number of MOSFETs connected in parallel with a total RDSon of 0,3mΩ. The temperature of the MOSFETs never rises more than 65 °C above ambient temperature.

The resistance shunted WSLP3921L3000FEA from Vishay allows accurate current measurement with very little power loss, ensuring safe fuse closure. Your certification AEC-Q200 and a precision of 1 percent with a resistance of 0,0003 Ω makes the WSLP3921L3000FEA ideal for security applications.

La card temperature monitoring It also helps to increase the level of security. This function is implemented with the NTC thermistor NTCS0805E3103JMT from Vishay, which is also AEC-Q 200 certified and has a resistance of 10 kW with a deviation tolerance of 5 percent.

The components are located in a FR4 card (flame retardant) double-sided measuring 125 × 60 mm. The smart eFuse can be controlled via on-board control elements and via an external microcontroller or mechanical switch. The consumption of the card stands at 53 mA when the electronic fuse is deactivated and 95 mA when you are “driving”.

Figure 3. Vishay's NTCS0805E3103JMT NTC thermistor with AEC-Q 200 certification is used to monitor the temperature of the card.

With all these features, Vishay's smart eFuse supports modern circuitry concepts and thus paves the way for the development of future-oriented vehicles.