- A seamless collaboration facilitates constant product innovations and quality improvements to raise industry testing standards

- A shared commitment to quality drives rapid delivery of dynamic, industry-leading solutions foundation testing, in an environment of supply chain constraints

- Molex's proven capabilities in connectivity, cabling and manufacturing automation enable PDI to fulfill one million product orders as sales double year-over-year

Molex today announced a highly successful collaboration with Pile Dynamics Inc. (PDI), the world's largest manufacturer of deep foundation testing equipment. Together, the companies are using the latest innovations in connectors, cables and sensors to revolutionize traditional quality testing of massive infrastructure foundations, such as bridges, skyscrapers and stadiums, without failure or error.

Based in Cleveland, PDI develops testing and quality assurance equipment to assess the integrity of deep foundation structures on land and in water. Over half a century, PDI's products have been used on construction sites in more than 100 countries, where its Pile Driving Analyzer® (PDA) has earned a reputation as the gold standard in pile testing. high tension dynamic loading and monitoring of pile driving. Through its commitment to quality and innovation, PDI provides accurate results in real time, in stark contrast to traditional testing methods that can take up to 10 days.

“Our proprietary method is much faster, more comprehensive, and can be performed at half the cost of other testing methods,” explained George Piscsalko, president of Pile Dynamics Inc. “All of our data is stored in the cloud, so so no in-person visits are needed, further reducing time, cost and carbon footprint. As PDI continued to add sophisticated sensors and technologies to its solutions, it became clear that we needed to partner with a more forward-thinking and proactive connectivity solution provider like Molex that could solve problems and really help drive our business forward.”

A shared commitment to quality and innovation

Initially, Molex's direct mount connector allowed PDI to resolve reliability and availability issues with an existing vendor, paving the way for a deeper level of collaboration. “Most exciting to us was PDI's clear position as a disruptive force in this industry,” added Daniel Koch, senior product manager, Molex Worldwide Consumer and Business Solutions Division. "They use technology and electronics in a way that has never been seen before in this industry."

PDI leverages Molex's extensive experience in highly demanding environments such as automotive, consumer electronics, healthcare, and data centers to meet rigorous performance requirements. For example, Molex has eliminated the need for manual intervention while testing splice connectors installed hundreds of feet underwater, allowing construction crews to test in less time and with significantly less risk. In addition, Molex embeds sensors directly into PDI's Thermal Wire® cable to speed and simplify production of the company's state-of-the-art thermal profiler, the Thermal Integrity Profiler (TIP™). With this, PDI can assess the quality of concrete both inside and outside of a rebar cage, while securely and instantly delivering test results, which are in the cloud.

Record demand met amid supply chain constraints

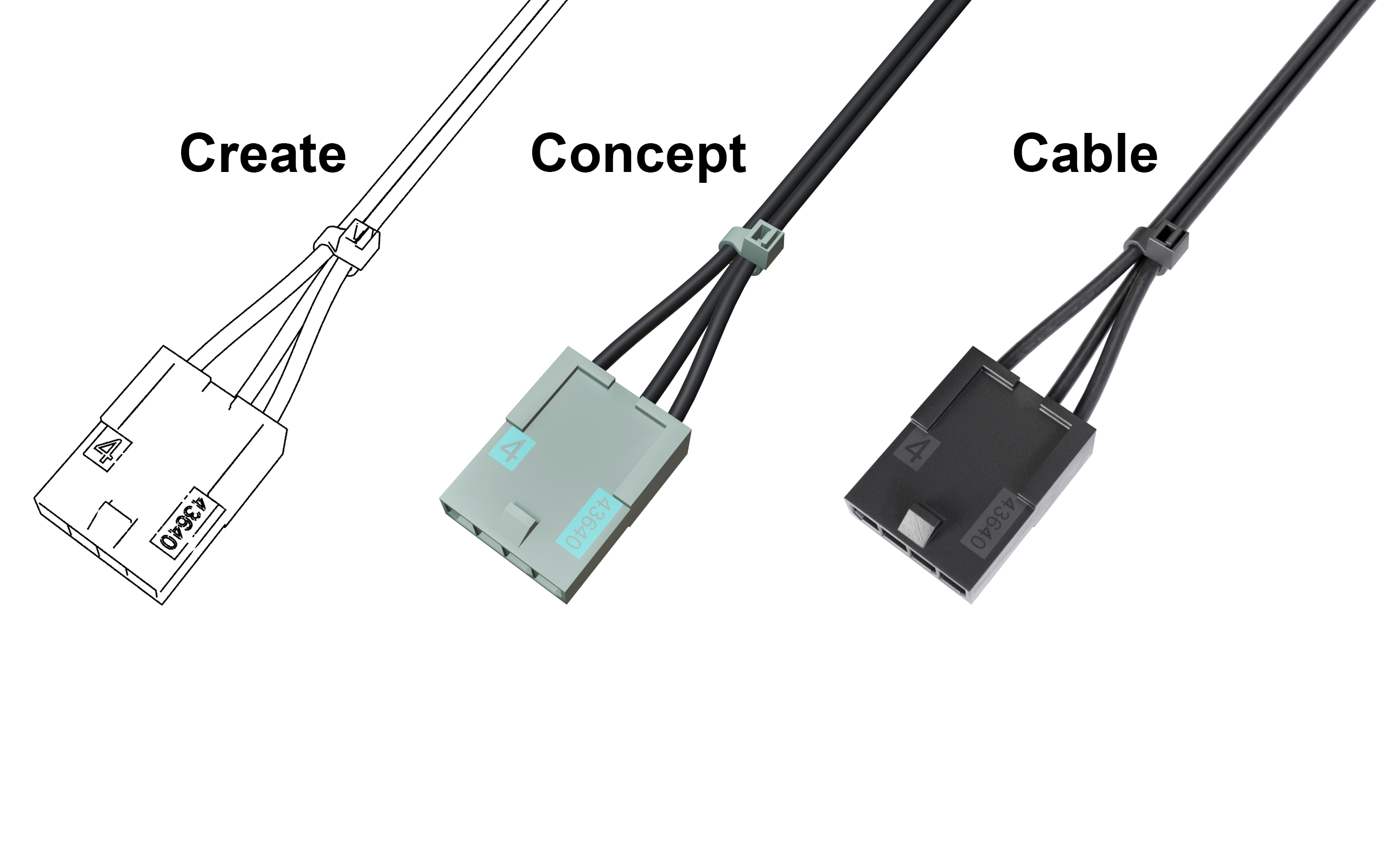

Molex has developed automation solutions to speed the production of custom cable assemblies, allowing PDI to build prototypes faster while accelerating the design of innovative products that feature new and different technologies. Molex cable assemblies assist in the early process, concept design, and prototype development phases, with a focus on reducing time-to-market and providing best-in-class support for pre-production, performance testing, quality and cost reduction. Furthermore, Molex's certified manufacturing facilities support design-to-manufacturing from initial production to high-volume, fully automated assembly.

During the COVID-19 pandemic, Molex was mobilized to help PDI ensure a steady flow of raw materials to increase production by aligning experts in global supply chain management, sourcing and logistics. Thanks to a reliable supply chain and industry-leading connectivity innovations, PDI expects to double its current sales next year, with sales projected in 2023 at levels two to three times higher than today. "For us, Molex is more than a supplier," says George W. Piscsalko, production manager at PDI. "They are an integral part of our business, coming up with solutions we really value and delivering them not only on time, but often ahead of schedule."