The global car market is undergoing a widespread transition to electric vehicles (EVs). Until now, vehicles based on internal combustion engines have improved powertrains to meet emission standards. These standards, along with comfort technologies and autonomous driving, have increased the efficiency of electrification in cars. In parallel to the increase in the number of electronic devices, the electrical consumption of the vehicle has also increased. Battery voltages have varied to accommodate higher consumption requirements and are associated with efficient power systems. This article discusses EV technology in high-voltage applications and introduces Samsung Electro-Mechanics' high-voltage MLCCs for automotive.

Vehicle electrification and battery voltages

The increase in car battery voltage is related to the trend towards electrification. To understand this trend, we must look back to see how the voltage of a car battery has changed. Until the mid-1950s, the operating voltage for vehicles was 6V. Since then, engine displacements have increased, requiring a larger electric starter motor. The 12V system was standardized by the need for more electronics, while early cars only required a small battery to start the engine and turn on the radio.

However, as the number of electronic devices in the vehicle increased over time, so did the need for more power. To solve this problem, it was discussed to increase the voltage from 12V to a system with a higher voltage capable of taking on the demand for more power. In the 1990s the 42V system was proposed and in 2011 German manufacturers standardized on 48V. Since then, hybrid cars and EVs have started to use higher voltages. Power (W) is voltage (V) multiplied by current (A). As power increases it is more efficient to raise voltage rather than current. When the current is increased, thicker cables are needed and the connector pins must also be changed. Both factors influence the cost of the hardware, hence the battery voltages increase instead of the current.

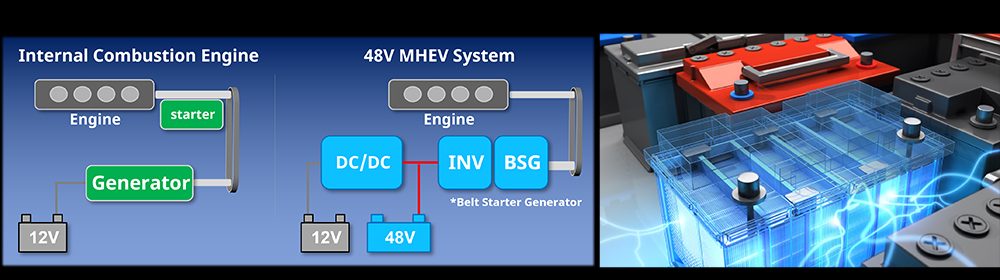

Battery voltage increase: 48V light hybrid system

The main reason the 48V system emerged in the 2010s was the passing of emission standards. Automakers producing internal combustion engines had to meet their emissions targets and increase fuel efficiency by improving powertrains to do so. Mild Hybrid (MHEV) is said to be a simple and economical hybrid system. The reason why car manufacturers preferred the MHEV is that it was easy to manufacture. The MHEV system can be manufactured by adding a 48V system to the existing internal combustion engine powertrain, thereby reducing emissions at a lower cost than a full hybrid vehicle. But the question remains: why 48V? The reason is that in many countries a voltage of 60V is considered low and not dangerous for the human body. Additionally, telephone lines have been using 48V power systems for the past 100 years, further demonstrating the safety of 48V systems in vehicles.

High voltage application in electric car

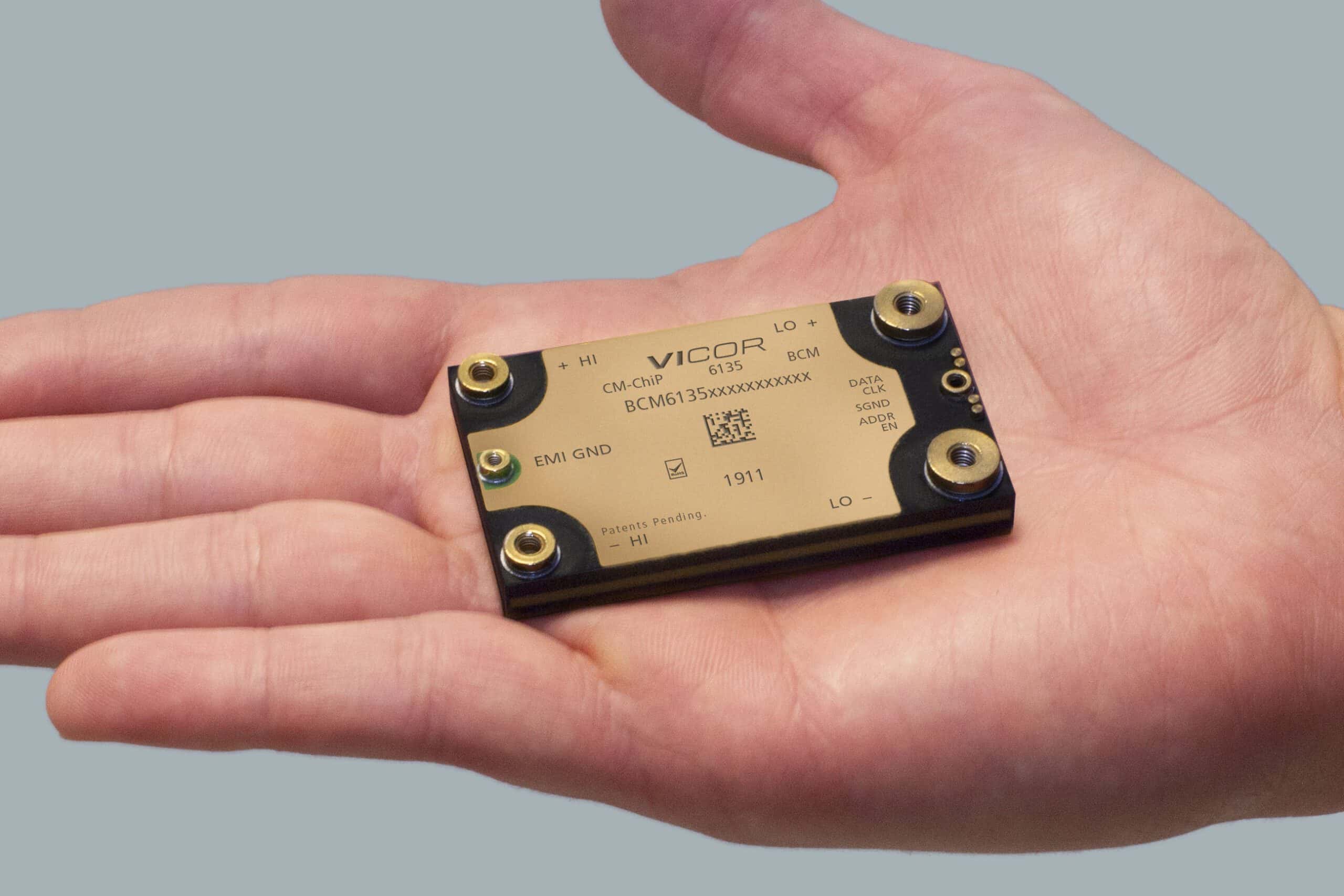

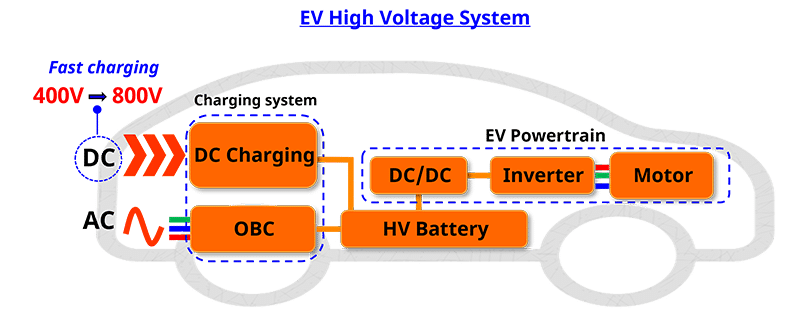

The basic configuration of the EV propulsion system consists of a high voltage battery, an inverter and an electric motor. EV propulsion systems use high voltage and the efficiency of an EV is tied to the efficiency of the DC/DC converter. Electric cars have various power conversion applications, such as low voltage DC/DC converter, on-board charger, and inverter. Various DC/DC conversion topologies are currently being applied to integrate similar applications. For example, on-board chargers (On Board Charger, OBC) and low-voltage DC/DC converters (Low-Voltage DC/DC Converter, LDC) are being developed for integration into the system, with the advantage of reducing the number of of components and save space.

High voltage MLCC structure to ensure reliability

How does the structure of a high voltage MLCC differ from a general MLCC? Reliability should be guaranteed in high voltage environments. MLCCs installed in high voltage applications are exposed to the risk of electric arcs or short circuits occurring within the MLCC. When the voltage is high, a strong electric field is formed around the MLCC which ionizes the surrounding air. Specifically, a powerful electric field is concentrated at both terminals of the MLCC. If it exceeds the activation voltage of the ionized air, an electric arc is produced that can cause a short circuit inside the MLCC. The structure that prevents this phenomenon is a shield inside the MLCC.

The floating design decreases the risk of a short circuit when a crack occurs in the MLCC, but is also useful for high voltage products. The floating structure distributes voltage in such a way that the voltage inside the MLCC is only half the voltage applied across the terminals. For example, when 1000V is applied to both ends of the MLCC, using the floating design only applies 500V to the dielectric layer of the MLCC, ie half of 1000V. It is certainly an advantage from a reliability point of view because it reduces the applied electric field between dielectric layers. Voltage and temperature are key factors in determining the useful life of the MLCC.

Samsung Electro-Mechanics' high-voltage MLCC ensures reliability in high-voltage applications. More detailed information on this matter and on the company's product range can be found on the web.