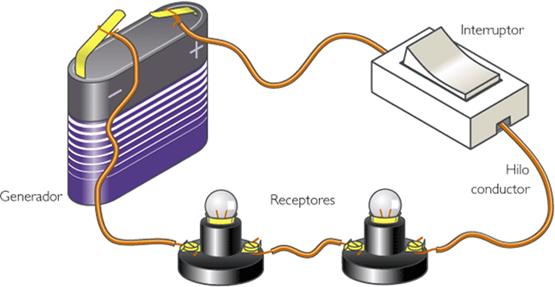

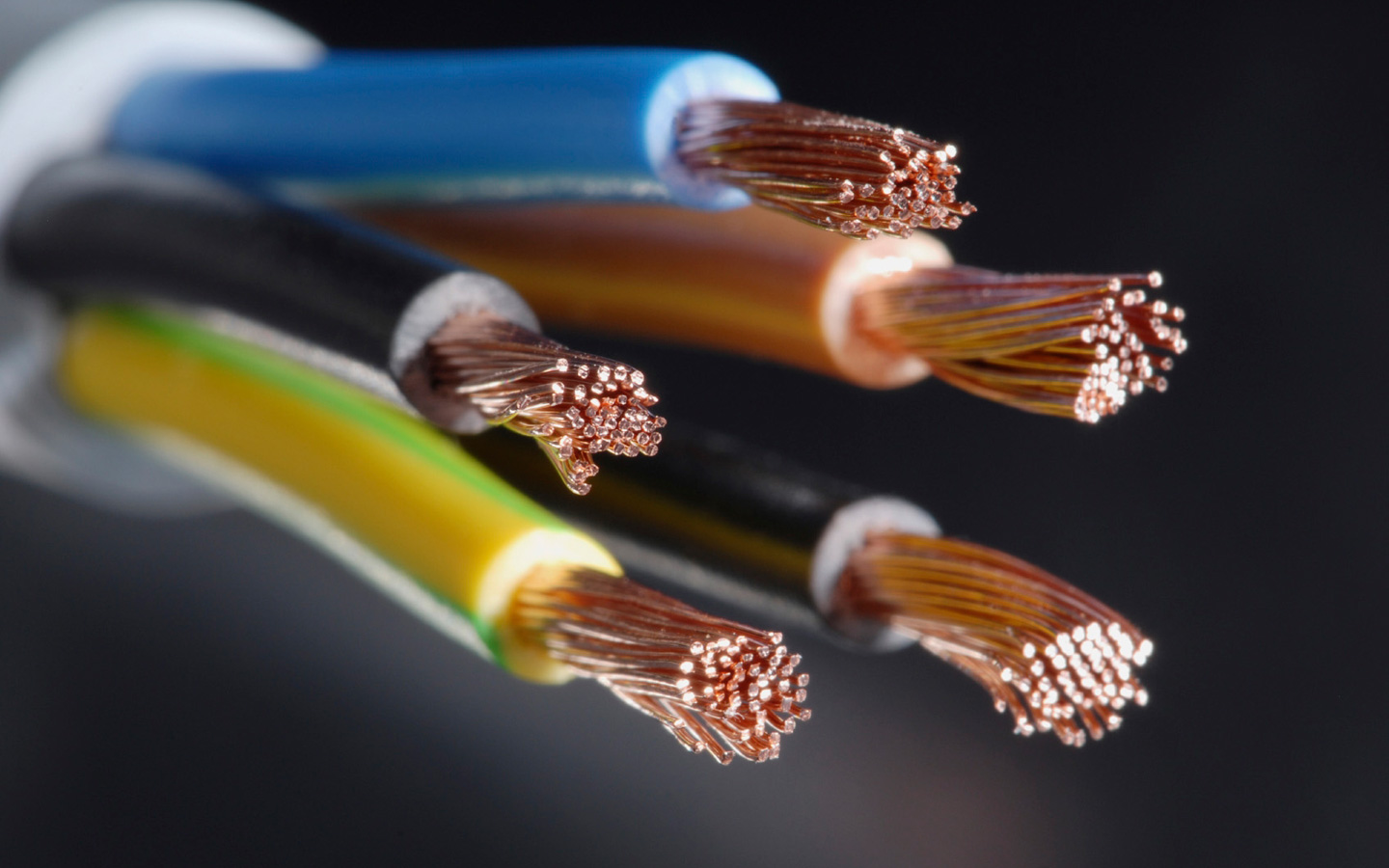

Electrical connectors are used to make connections between electrical cables, or between electrical cables and some element of the circuit. We also have the so-called "Electrical Terminals" used to join a cable with an electrical device.

Note: Connections or joints of cables only with insulating tape are prohibited in any installation.

Electrical circuits are made up of a multitude of components, including cables and wires. Electrical connectors are used to join together to form a continuous path for electrical current to flow, drastically reducing the time, effort, and labor required to fabricate, mate, and also install electrical devices, their components, and wiring.

Electrical connectors have male ends and female ends (connectors) that either connect together to form a permanent connection or a temporary connection that can be attached and removed.

Let's see the properties and classes of electrical connectors most used.

Properties of Electrical Connectors

The first thing when we choose an electrical connector will be to know perfectly:

– The section of the cable or cables that the connector will join, generally in square millimeters.

– The Current or Intensity to support: the current rating describes the maximum flow rate of electricity (current) for which a connector is designed. This is measured in amps (A or amps). The current rating on a connector will usually be in the 1A to 50A range, but larger ones are available for special applications.

– Voltage or Working Voltage: The voltage rating describes the range and type of voltage for which the connector is designed and can withstand. It is measured in volts (V) and can be for alternating current (AC) or direct current (DC). Generally, the ratings can be 12V, 24V and 48V for direct current and 50V, 125V, 250V and 600V for alternating current.

– Operating Temperature: The operating temperature range describes the range, recommended temperature, and minimum/maximum safe operating temperature for the electrical connector.

Once we know these properties that the union will have, we proceed to select the type of electrical connector.

Types of Electrical Connectors

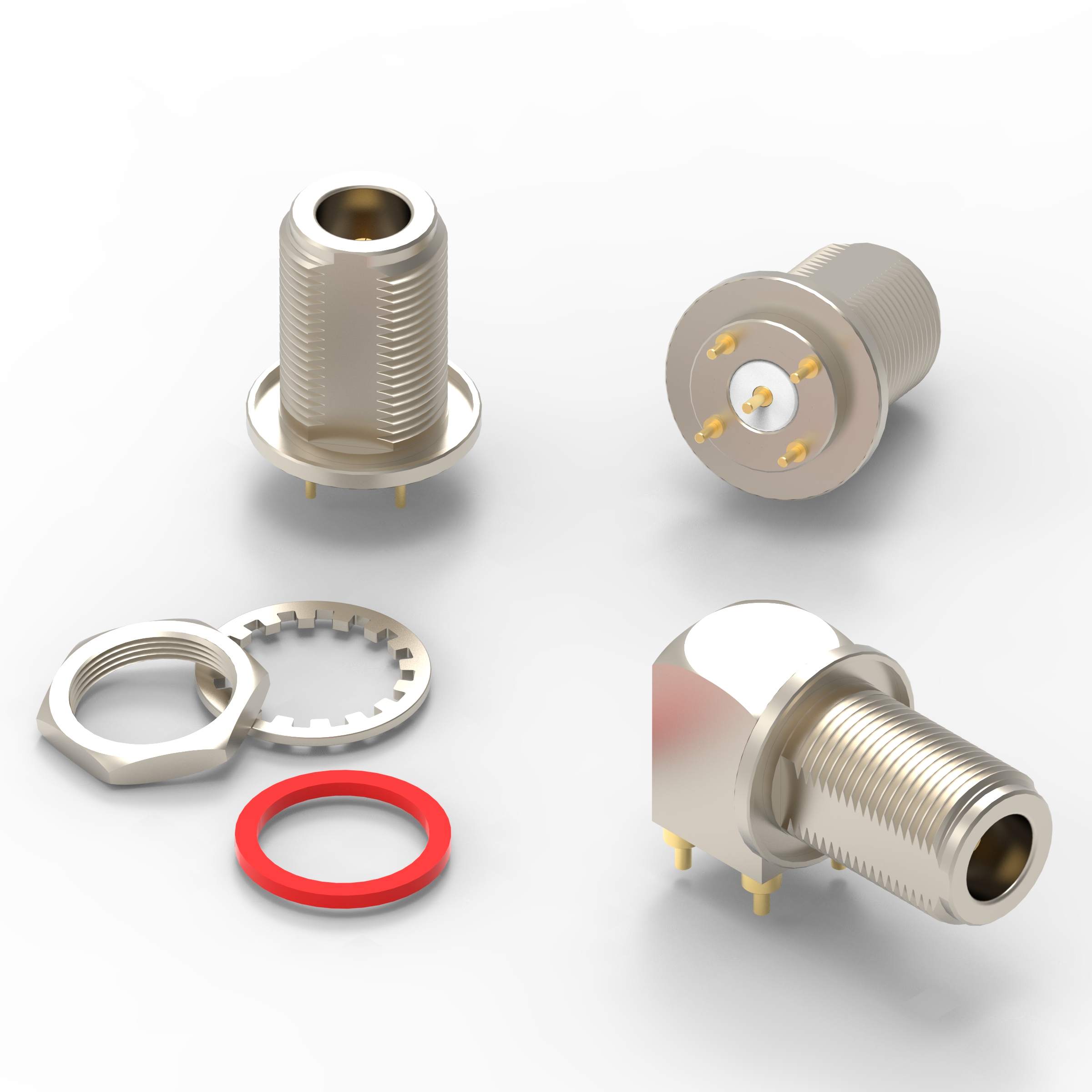

The most used connector for joining cables is the power strip or terminal. The connection of the cables is made through a threaded screw that tightens the conductive cables to be joined or through pressure on the cables. It is used in interior installations, for example in switchboards, in lighting installations for the connection of devices to the fixed installation or in connections in junction boxes. Let's see the most used rules.

As regards the most widely used terminals, they are called “Pre-insulated Terminals” since they have insulation between the cable and the connection metal, covered by a colored plastic (yellow, blue, red, black…). But not all are separated, as you can see in the image below.

The models that exist are called depending on the shape of the terminal: fork, tip, or round, or flat-tongue. The flat (or Faston) is the female terminal and the so-called tongue is the male. They are used in electronics and electricity to easily connect and disconnect cables.

The fork and round ones are used in screw connections and the pointed ones where there is little space for the connection.

To join the cable to the terminal, it is necessary to disfigure the plastic using terminal pliers or a crimper.

Another widely used type are the union sleeves in which a cable is inserted on each side and with a crimper it is crushed to fix the cables to the sleeve, previously stripped at the ends.

Before selecting an electrical connector you have to know the properties that we need the connection to have.

Other types of connectors are:

Spring connectors have an internal spring that ensures a fast and reliable connection. They are a fast, safe and reliable connection system for lighting and cable splicing. They are used particularly for joining and insulating cables in a through splicing operation and are suitable for strong flexible cable.

– Rail Terminals for automations: These are terminals to be placed on the joining rails just like the contactors and are generally used in automations.

We have other alternatives depending on the job they are going to have:

– Push-in: These are terminals for directly inserting the cable without the need for tools.

– Locked connectors: A locking mechanism ensures connectors are held in place, preventing connections from accidentally breaking or dislodging when the connector is bumped or moved.

– Hermetically sealed connectors: These connectors are designed to work completely underwater and resist pressure to certain depths.

– Waterproof connectors: These connectors protect electrical connections against water damage from splashes or eventual moisture.

– Oil/Moisture Resistant Connectors: These are designed to protect electrical connections from damage caused by oil or moisture.

– EMI or RFI Filtering: Additional features built into the top of the housing shield connectors from Electromagnetic Interference (EMI) or Radio Frequency Interference (RFI), which can affect circuits that carry electrical signals.

– ESD-protected connectors: Protected against the discharge of electrostatic electricity that can damage wiring and components.

In photovoltaic solar installations, connectors protected against water, humidity (watertight) and against eventual disconnections are used. The most used are the so-called TYCO, although the MC3 and MC4 are also used.

Source of information used: https://www.areatecnologia.com/electricidad/conectores-electricos.html