The ACURO encoder® AD37 allows security applications with high speeds

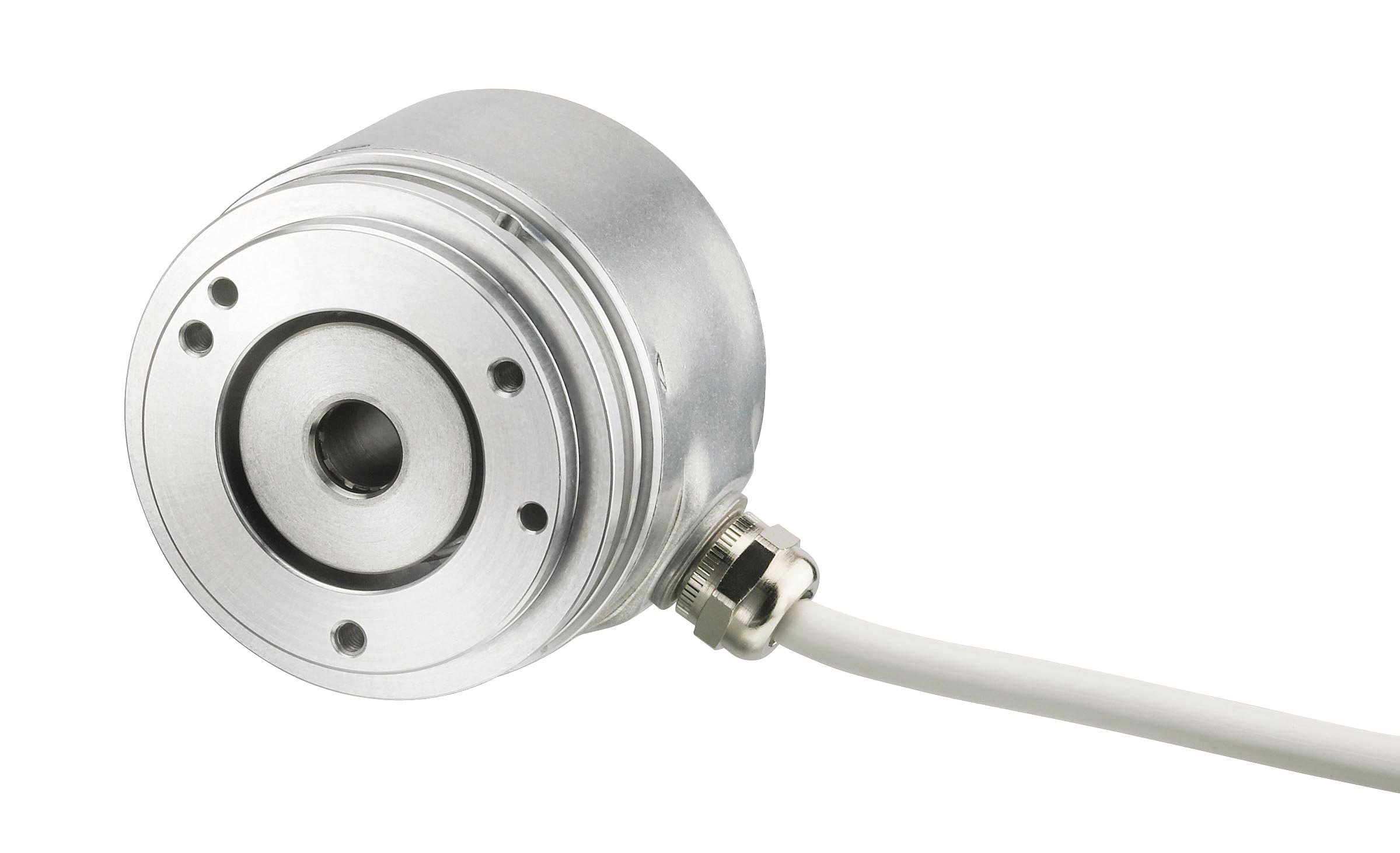

El ACURO absolute encoder® AD37 from Hengstler has been specially developed for highly dynamic and safety-critical motion control applications with high data rates and distances. With a mounting depth of just 29mm, the AD37 is the most compact motor feedback encoder in its class and the only one in its class that meets Safety Integrity Level (SIL3, PLe Cat.3) specifications.

Hengstler has adapted its ACURO absolute encoder® AD37 exactly to Bosch-Rexroth controls, which are often used in high-end applications in industry. The target group includes not only users of Bosch drives, but also motor manufacturers who produce drives for these drives.

the ACURO® AD37 offers a very high precision of ±36 arc seconds, as well as a high resolution of 20 bits in singleturn operation and 12 bits in multiturn operation. This makes the encoder the ideal device for all dynamic applications with high requirements for safety and precision. ACURO data transmission® AD37 is realized with a very high signal quality, so the encoder can also be used for applications with cable lengths up to 100 m. The combination with high functional safety is unique on the market for encoders of this class.

Another advantage of the ACURO absolute encoder® AD37 is your Single Cable Solution for cost and space saving applications. Thanks to the ACURO interface® link developed by Hengstler, the encoder can transmit not only safety-relevant data, but also the motor winding temperature, which is very important for drive performance. Unlike conventional encoders, the AD37 does not require any additional cables for temperature data transmission:

The motor winding temperature is determined at the encoder and transmitted to the controller together with the position data.

The axis of the ACURO® AD37 is not directly connected to the motor shaft, as is the case with conventional encoders, but via a coupling hub. Since this thermally insulates the encoder shaft, the motor can also be run at very high speeds. This enables users to optimally exploit the dynamic possibilities of constantly evolving electric drives.