Clément Amilien, Global Product Manager for Integrated Sensors.

Until now the evolution of integrated current sensors (ICS) has been slow and gradual. Current measurement technology has been increasingly developed over the years to focus on the miniaturization of high-density components that can also achieve high levels of performance. Bulky sensors are inevitably losing their market share in parallel with the arrival of more streamlined competitors.

The question is how to be at the forefront of the market and investigate what users need. Gaining this information and then developing products that meet those needs requires a top-down, bottom-up approach of forecasting market trends and conducting customer surveys. A really close relationship with customers can be very advantageous when working in the semiconductor market. Customers generally know what they want from their ICS and their feedback has proven to be instrumental in driving this evolutionary process.

Customer input has helped identify the four key elements they look for in current sensors:

- performance at different temperatures; refers to drift and sensitivity variation and is the most important characteristic

- how much current an embedded solution can handle; a small current sensor with a built-in primary has a limit of 30A or 50A continuous for the current it can handle, and technological advances are all about exceeding these limits

- overcurrent detection; a protection threshold by continuously monitoring the overcurrent

- insulation (basic or reinforced depending on the system voltage) as a possible key factor when choosing the sensor

closed loop and open loop

For the past several years, users have been able to take advantage of closed-loop Hall effect technology; LEM itself designed a special closed-loop ASIC (Application-Specific Integrated Circuit), while open-loop technology represented a much lower cost solution. This technology led to the development of the HLSR-series current transducers, a compact, low-cost PCB-mounted solution that took miniaturization to new levels.

The next step came with HMSR, a highly isolated ICS designed to meet continuing market requirements for cost reduction, performance improvement, and miniaturization. This new series marked the expansion of miniature current sensors to measure isolated AC and DC current in highly demanding switching power applications within commercial and industrial markets. Microcore-based open-loop sensors with reinforced insulation and overcurrent detection, the HMSR devices incorporated a low-resistance primary conductor (to minimize power losses), a miniature ferrite, and a proprietary ASIC allowing direct measurement. of current and consistent insulation performance. All these features make HMSR ideal for high voltage applications that demand high accuracy and significant immunity to external fields. The micromagnetic core means the device was especially useful in power electronic applications that are often heavily disturbed.

For these reasons, power electronics engineers have been using analog HMSR sensors for many years to measure DC and AC currents. They have particularly enjoyed the benefits of a compact current sensor with strong immunity to stray fields, reinforced insulation, and a 300kHz bandwidth.

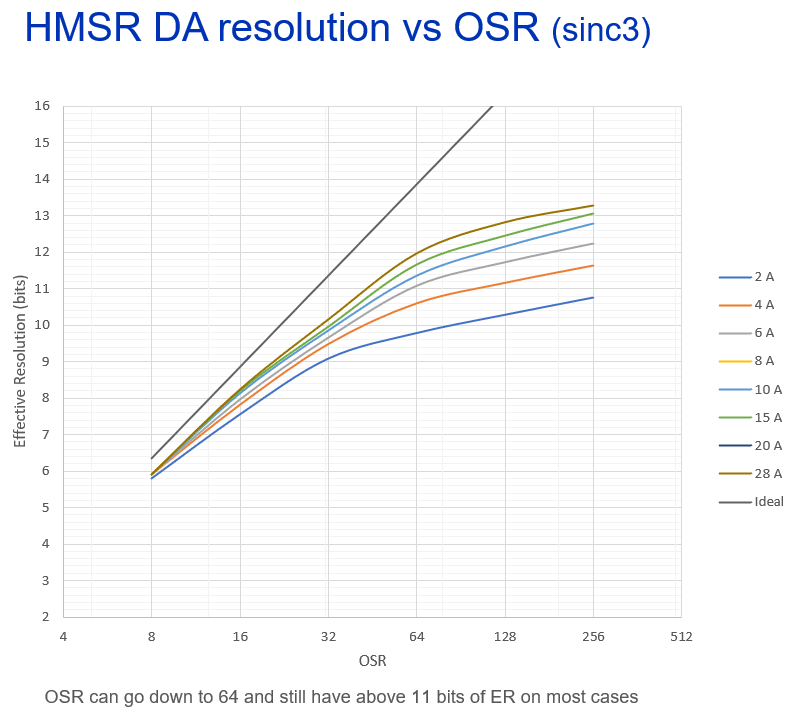

The latest solution in this continuing evolution of integrated current sensors is the HMSR DA, the first ICS on the market to deliver a Sigma Delta bitstream output, measure low currents, and still achieve high resolution. Using a digital signal means that a fixed delay is introduced into the sensor output (also known as response time), while the quantization noise from the A/D converter (ADC) is significantly reduced and the filter Digital ensures even better resolution with a Sigma Delta Modulator (SDM) using noise modeling. Creating an ADC is easy by combining the modulator and a digital filter. Among its advantages are a reduced number of connections, the possibility for each user to define the performance levels of their own system and that users can have two or more converters with different performances. This type of architecture is especially indicated for economic CMOS processes.

Among the other characteristics of a digital current sensor is the settling time, also known as response time or delay. With a clock of 10MHz and an oversampling ratio (OSR) of 128, the settling time of an SDM would be about 38,4us. Another advantage of using a Sigma Delta data stream at the output is its flexibility, since different digital low-pass filters can be applied on the client side, depending on the specific needs of the application. The user can choose between a slower, higher-order filter if a high-resolution result is required, or a faster, lower-order signal for faster results but lower resolution. These features, among others, make the new HMSR DA sensor outperform other ICS with digital output, including even a digital version of the HLSR devices and the HO series of open loop current transducers.

typical applications

The market is proving receptive to a digital output ICS because it can offer superior signal shaping and lower noise levels at the same time, as well as reduced cost and a smaller mechanical footprint. Typical applications for this type of ICS include robots, servo drives, sewing machines, CNC machine tools, welding equipment, and automated guided vehicles.

In recent times, the automotive sector has begun to show interest in these sensors. R&D organizations and manufacturers specialized in this market are very interested in a digital solution being immune to external noise, including electrical and magnetic noise, which as is well known cause great difficulties when using analog signaling.

Digital ICS development plans

As the first step in LEM's development of digital ICS, literally the first of its kind on the market, the HMSR DA sensor offers users 11-13 bit resolution and 10MHz clock.

The ultimate goal would be to approximate the current levels of traditional sensors with an integrated current sensor. At the moment, the HMSR DA can reach up to 30 to 36 A continuous current or 35 A peak current but the following generations would try to reach 100 A continuous current while keeping its small size and its mounting on a printed circuit board . Future versions will also attempt to eliminate the need for a magnetic microcore, which will improve frequency response and eliminate potentially problematic magnetic disturbances.

Ideal for applications subject to noise, distortion and interference, the HMSR DA achieves real cost savings by allowing customers to reduce their bill of materials. It does this by bundling into a single device an otherwise much more complex and expensive system, typically including a shunt resistor, digital isolator, and low/high feed circuitry with diodes and capacitors. The shunt is by no means the best solution due to the thermal noise it generates at high currents. Another problem is the space required to contain these devices separately, while with the HMSR DA there is only one chip that performs the same function as those three elements and its offers a direct output to the clients. The new sensor also provides customers with features not available in separate devices, such as an ASIC and overcurrent detection, which the shunt does not offer.

Different ways of approaching system design

There are also different output modes available: simple with bitstream and clock but also differential, thus eliminating the need to purchase output drivers to convert from simple to differential. A solution based on RS-422 data and a low-voltage differential signaling (LVDS) receiver will provide the output and output inverted, as well as the clock and inverted clock signal, which is important when handling differential signals because It allows to eliminate all kinds of noise with low consumption and high speeds. With the new digital sensor, all these functions are integrated into a single device.

The HMSR DA sensor is expected to allow engineers to think in new ways to approach their system design. Customers will also be able to use filters to tailor the sensor to meet their requirements when working in any environment that requires clean signals but has traditionally been exposed to electrical noise, vibration and magnetoelectronic noise. Distortion and interference are major problems in such demanding applications and only by pushing the limits of digital output can truly revolutionary developments be achieved that solve the problems of noisy systems that are placed on the market.

Digital output is still in its infancy and, even today, some customers may be reluctant to go this route. However, it is a powerful trend that will spread much more in the coming years. That's why it's critical to closely monitor this technology and encourage credible user feedback about the feasibility of applying digital output solutions in your industry.

The evolution continues...