High level security with low installation costs

When installing energy storage systems, attention is focused on three key factors: security, installation cost and correct execution. The new plug-in connection technology from Phoenix Contact now enables such systems to be installed safely, quickly and cost-effectively (title picture / figure 1, main picture).

Electric energy storage solutions are key to paving the way to the All Electric Society. Power generation is becoming increasingly decentralized, while electrification in many areas of society is advancing relentlessly. This trend is also causing an increase in the use of energy storage systems. They store energy and therefore enable the reliable availability of renewable energy. They are also used as buffer or backup storage systems, thus relieving the load on the electrical grid. While the main focus in storage system development has been on battery cell performance capabilities in recent years, other system components are also becoming increasingly important (figure 2).

battery modules are connected to each other to form a system: connection technology

it is a critical factor for the performance of the entire system.

©engineerstory@shutterstock

Energy storage systems are made up of a large number of battery modules that must be connected together during installation. The performance of the entire system depends on the quality of each and every connection. In this sense, it is very important that each contact point transmits the current safely and reliably. Therefore, there are three issues of key importance during installation: The safety of the installer, the amount of work required for the installation, and avoiding errors during wiring.

Until now, a large part of the systems have been installed with a simple screw or stud connection. In terms of material costs, this connection technology is undoubtedly competitive. However, if the time required for installation is also taken into account, the cost advantage quickly fades, even if there are only a few touch points. During installation, make sure the installer places each screw connection and tightens it to the correct torque to create a reliable electrical connection. In a storage system with several hundred or even thousands of battery modules, not only does the installer have to screw each connection into place, but there must also be a high level of repeatability in the process. In addition, connection technology with a simple screw or stud connection often does not provide adequate touch protection for the installer, and therefore harbors a significant risk of injury.

Phoenix Contact offers a perfect plug-in technology solution to counteract the disadvantages of the connection technology described above. It can be supplied pre-assembled together with the battery modules, meaning the only work left during installation is plugging in the connections.

Each application has specific requirements

The connection technology requirements differ considerably depending on the size and intended application of the storage system. For example, when installing small home storage systems, the on-site installation situation must be approached with flexibility: the connection technology must allow this flexibility. In contrast, in the case of large storage systems, this factor is of little importance. The interior layout of a storage container is usually highly standardized. Since a large number of modules have to be connected in such an application, the focus is on installation time and the cost of the connection solution.

Phoenix Contact offers plug-in solutions for conventional applications, from small home storage systems, through industrial storage systems, to large-scale storage systems. In addition to the widely used front connection technology, there is now a completely redesigned plug-in system for connection to busbars. All solutions have one thing in common: they have been specially designed for each energy storage system application and therefore meet its specific requirements. All connectors have been designed for system voltages up to 1.500 V DC and feature mechanical reverse polarity protection that reliably prevents mismatch of the positive and negative terminals of the battery modules. In addition, the installer can clearly distinguish between the different polarities thanks to their different colors.

Domestic, industrial and large-scale storage systems

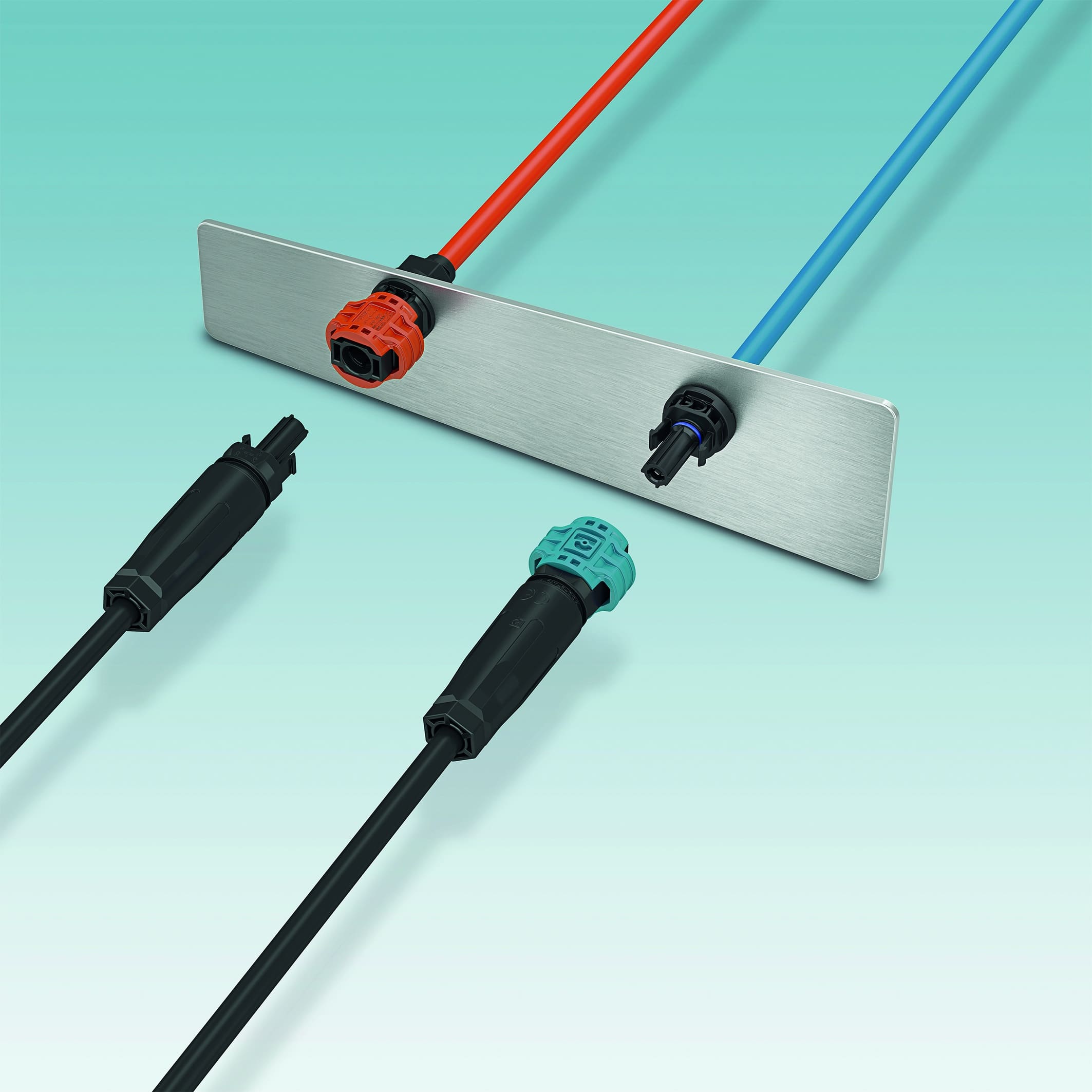

Home storage systems are usually connected to a photovoltaic installation through an inverter to store the electricity generated in it. Therefore, the connection technology has to meet similar requirements to the established inverter connection technology. Phoenix Contact has developed a version with a coded pin connector pattern to prevent mismatch of different strings. This prevents both the short circuit of the battery poles and the unintentional combination of the connections of the battery and the photovoltaic system. In addition, the red and blue connectors on the battery are visibly different from the connections on the PV system (figure 3).

The different colored and mechanically coded connectors are

They are clearly distinguished from conventional photovoltaic connectors.

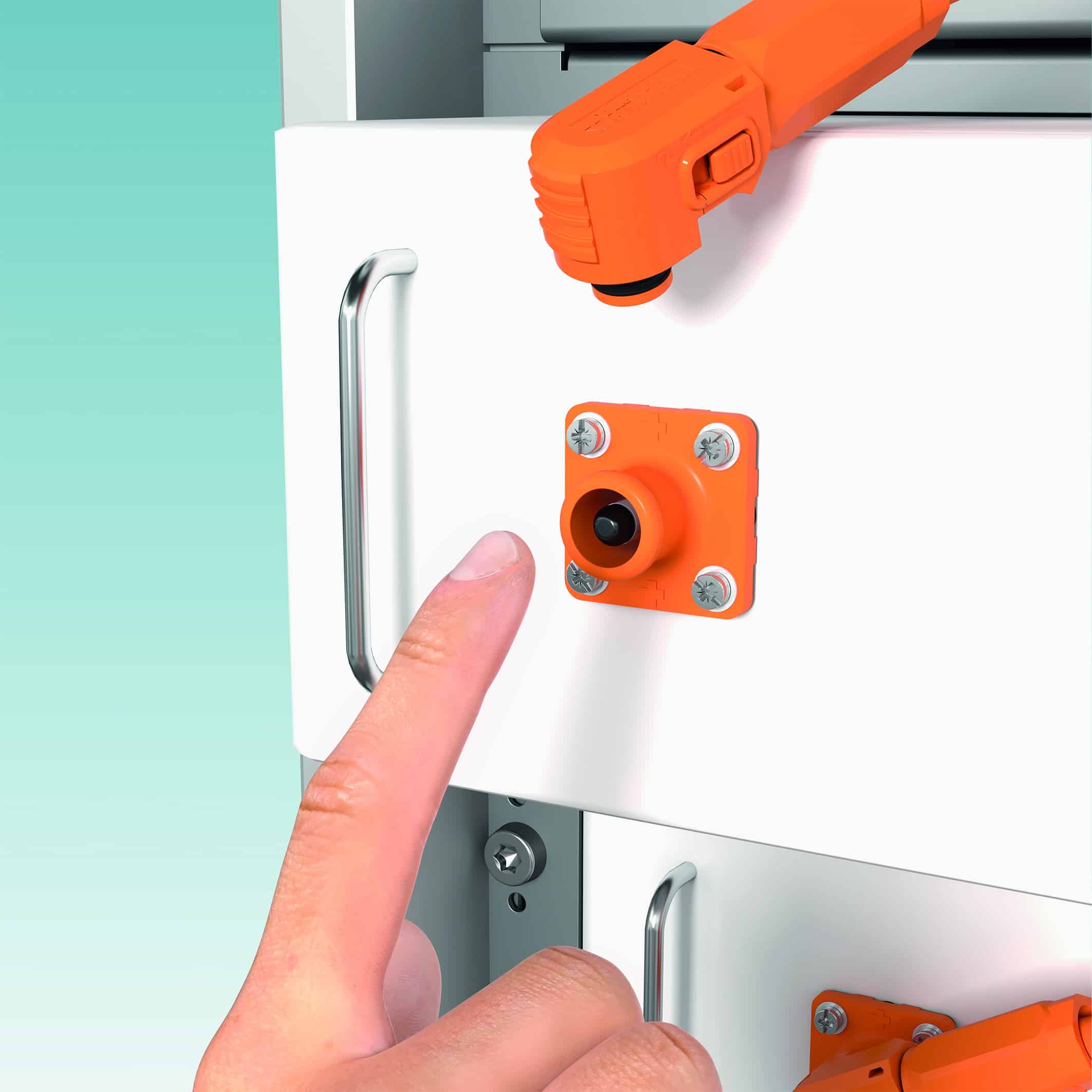

The new battery pole connectors from Phoenix Contact for use in industrial storage systems are characterized by high currents, flexible connection directions and different connection technologies on the device side. Sections from 16 mm² to 95 mm² allow currents of up to 350 A to be transmitted. Extensive protection against contact guarantees the safety of the installer, even when it is not plugged in. In addition, since the connectors can rotate 360°, they can respond flexibly to different installation conditions. Additionally, device manufacturers can choose between various connection technologies, such as rod connection, threaded stud or crimp technology (figure 4).

Large-scale storage systems are already largely standardized to keep costs as low as possible. Standard containers are equipped with racks, as well as busbars for power distribution; Why not also adapt the connection technique to these conditions? To do this, Phoenix Contact has developed a plug-in system that makes contact directly on the busbars. This eliminates all the wiring effort previously required for power connections. A high tolerance offset of +/-4 mm guarantees a reliable interlock on the busbars. The modular design of the connector, similar to a terminal block, allows currents from 40 A to 200 A to be transmitted (figure 5).

pluggable making direct contact on busbars (left)

together with the flexible cable-based solution using connectors of

battery poles (right).

Prospects for an energy revolution

The evolution of electric mobility is also increasing the demands for energy storage. High currents and voltages must be used to achieve ever higher charging powers. However, the conventional cable connection technology used until now is reaching its limits. Instead, the plug-in system has a number of advantages: The power connections at the rear of the battery module come into direct contact with the busbars, at a safe distance from the installer. Thanks to the modular design of the connector, the concept can be easily upgraded for high currents in the future. This is possible, among other things, due to the high current-carrying capacity of the busbars, which are already used today for power distribution. Furthermore, this high-current concept is more cost-effective than cable-based connection technology, a factor that will play an increasingly important role in the price-driven energy storage market, particularly for large-scale storage systems. scale.

Summary

Pluggable connection technology increases the safety of energy storage systems and at the same time reduces risks and costs during installation. With intelligent concepts, even future requirements for energy storage systems can be met. Therefore, connection technology will also play its role in the safe and reliable supply of energy within the All electric society.

Connection technology for energy storage: the advantages at a glance

- Future-oriented connection technology: Voltages up to 1.500 V

- Flexible use: connections are possible on the front or rear of the battery module

- Quick installation: no wiring effort, thanks to the pluggable interface

- Safe installation and maintenance: extensive protection against contact, even when not plugged in

- Reliable connection: Clear information during connection guarantees a high degree of safety