Lighting is a critical element in the design of safe, efficient and profitable industrial environments in various activities, such as logistics, machine operation, control cabinets, work stations and manufacturing lines. In an increasing number of cases, LEDs can offer superior lighting solutions. Compared to traditional fluorescents, metal halide, high pressure sodium, and other lighting technologies, LED luminaires are more energy efficient, lowering running costs, and longer lasting, which reduces maintenance costs. Industrial luminaires are often used in harsh environments and may be required to include ingress protection and specific levels of power quality, as well as support occupational safety and sanitation. Balancing these various requirements complicates the luminaire selection process.

This article reviews performance metrics such as lumens, wattage, efficacy, lux, lumen zoning, correlated color temperature, color rendering index, rated life, and costs associated with fixtures. industrial luminaires, with special attention to LEDs. It then details environmental considerations, including requirements for ingress protection, total harmonic distortion, and power quality requirements, as well as lighting for hazardous environments. Finally, the article concludes by presenting specific solutions from Banner Engineering for lighting pick-to-light systems, forklift guidance and general workstation lighting, machine lighting and control cabinets ( Figure 1).

performance metrics

The light level specification is the basis for selecting the optimal luminaire for a given application. There are numerous parameters to consider, from the operating efficiency of the luminaire to the imitation of standard white light. Start with a single candle or candle (Cd). Cd is a basic SI unit that measures the luminous intensity of visible light emitted by a specific source (standard candle) in a specific direction. Starting from the Cd concept, important metrics to compare luminaires include:

- Lumen (lm): Luminous flux equal to the light emitted at a unit solid angle by a uniform point source of a Cd, taking into account light output in all directions.

- Watts (W): Electrical power consumption: For DC circuits, W = VCC x amps; for AC circuits, W = VRMS x amps.

- Efficacy (lm/W): The efficiency with which a light source produces visible light.

- Lux (lm/m2): Intensity of light incident on a surface, perceived by the human eye.

- Lumen zonal distribution: Distribution of the lumens emitted by a luminaire in zones in discrete vertical planes. It is used to determine the spacing requirements of a luminaire.

- Correlated Color Temperature (CCT): The temperature, in Kelvin (K), of a blackbody radiator with a chromaticity equal to that of the light source. The CCT of white light goes from 2700K to 6500K.

- Color Rendering Index (CRI): The ability of a light source to faithfully reveal the colors of various objects compared to an ideal or natural light source. CRIs range from 0 to 100. Incandescent bulbs have a CRI of 100, LEDs have CRIs ranging from 80 to 90+.

As lighting technologies have evolved, the process of specifying the optimal solution has become more complicated. For example, the efficacy of LEDs is substantially higher than that of fluorescents and High Intensity Discharge (HID) lamps. While fluorescents and HIDs emit light in all directions, LEDs are directional. The bottom line is that metrics are more useful for comparing LED to LED, fluorescent to fluorescent, etc. To compare different lighting technologies, users often have to evaluate samples side by side to determine which one is best.

In addition to the quality of light produced, users must take into account the Total Harmonic Distortion (THD) and Power Factor (PF) of the ballast or driver powering the fixture. The THD is a measure of the distortion of the electrical current reaching a power electronic converter. Lower THD means lower inrush currents and higher efficiency in a building's power distribution network, as well as lower demand on the local utility. The IEEE 519-2014 standard is a useful reference for understanding harmonics and applying harmonic limits in power systems. THDs of 20% or less are normally required. FP is an equally important metric. A load (ballast or driver) with a low PF draws more current than a load with a high PF for the same output power. PF is a dimensionless number between 0 and 1. Ballasts and drivers must have a PF of at least 0.9.

Lifetime and cost considerations

LEDs typically have a lifespan of over 25.000 hours, but their efficacy and luminosity decline as they age. The useful life of LED luminaires is based on the number of hours it takes to drop to 70% of the initial light output and is called the L70 parameter. Non-LED lighting technologies suffer catastrophic failure at some point; their useful life is defined as the number of operating hours in which 50% of the units are expected to have failed. Non-LED technologies also experience declining light values as they age. This effect, called lamp luminous flux depreciation (LLD), varies across lighting technologies (Table 1).

|

Table 1: Comparison of Lamp Lumen Depreciation and Rated Life. (Table source: Banner Engineering)

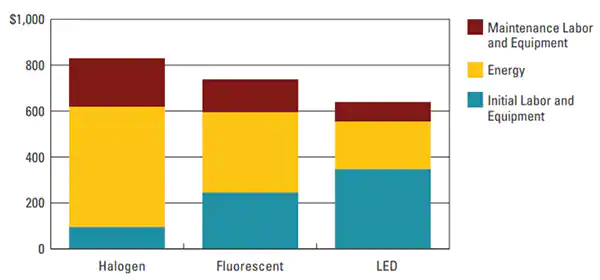

To compare the cost of lighting technologies, users must take into account the initial cost of labor and equipment, plus the costs of energy, maintenance labor, and equipment over the life of the luminaire (Figure two). Initial labor and equipment costs can be overcome due to increased energy efficiency and reduced maintenance needs, and longer lasting and more efficient LEDs can yield significant savings over their lifetime.

environmental requirements

Luminaires used in industrial facilities must be designed to withstand hazardous conditions. The National Electrical Code defines three types of hazardous locations:

- Class I: flammable gases or vapors

- Class II: combustible dust

- Class III: easily flammable fibers or frills

US Federal regulations require: “Equipment shall be marked to show the class, group, and operating temperature or temperature range, based on 40°C ambient operation for which it is approved.” »

Ingress Protection (IP) ratings are important and are indicated by two numbers. The first describes the equipment's resistance to solid foreign objects, such as dust, and the second describes the degree of protection against water. IP67 rated luminaires are dust and water resistant, making them suitable for many industrial environments, and can withstand brief immersion in water. IP68g rated luminaires offer additional protection and are more resistant to oil and water penetration.

Vibrations and extreme temperatures are common in industrial environments. The fine filaments, delicate components, and glass casings used in some lighting technologies can be especially vulnerable to damage from vibration. LEDs have no delicate components and are much more resistant to vibration and impact. Although mechanically strong, high ambient temperatures tend to reduce the effectiveness and life of LEDs. On the other hand, compared to other lighting technologies, LEDs are more suitable for refrigerated warehouses and other facilities where temperatures down to -40°C occur.

Pick-to-light luminaires

Pick-to-light systems can reduce the costs of warehouse picking operations thanks to greater efficiency, productivity and precision. For pick-to-light installations, Banner offers the EZ-LIGHT® K50L series, including the K50LGRASXPQ (Figure 3). K50L luminaires are offered with one LED (green), two LEDs (green and red), or three LEDs (green, red, and yellow), depending on the model, and are vibration resistant. The K50LGRASXPQ offers green and red LED illumination, as well as a multi-tone audible alarm. Features of the K50L series include:

- Easy to install with bright LED indicators and audible alarm

- Strong and fully sealed. With degree of protection IP67 or IP69K according to DIN 40050-9, depending on the model

- These autonomous luminaires do not need an external controller

- Immunity to Radio Frequency Interference (RFI) and Electromagnetic Interference (EMI)

- The audible alarm on IP67 models has an adjustable intensity that can be continuous or staccato

- Flexible installation with 12 V inputsCC at 30 VCC and reverse polarity protection

Forklift guidance lights and sensors

Forklift drivers can have obstructed vision, forcing them to dismount multiple times when placing difficult loads. The efficiency of material handling operations can be increased through the use of forklift guidance lighting and sensors. For example, Banner's model WLS27PXRGBW285DSQ luminaire is part of the WLS27 Pro Series and is 285mm long, has IP66, IP67 and IP69K environmental ratings, and includes red, green, blue and white LEDs (Figure 4).

All WLS27 Pro series luminaires can display multicolor animations at different speeds and patterns and can be segmented, making them highly suitable for forklift guidance systems. With unbreakable co-polyester casings on aluminum frames, the WLS27 Pro units are shatter and impact resistant. Their IP69K degree of protection allows them to function during harsh washdowns and in outdoor environments. Built-in counter and timer functions allow them to display time or quantity information, including distance and position, using pulse signaling.

WLS27 Pro luminaires can be combined with the Q5X multifunction laser sensor to implement forklift guidance systems (Figure 5). The Q5X has a range of 50mm to 5m. Other features are:

- Reliable detection of light and reflective objects, multicolor targets, black targets on a shiny metallic background, black targets on a black background, and dark objects (<0,1% reflective black targets)

- Dual learning mode measures both light intensity and distance

- 270 degree swivel to accommodate a variety of mounting constraints

- Programmable via IO-link, remote teach, on-board user interface or optional remote sensor display

General lighting options

Banner's WLB32ZC285PBQMB is a 285mm long, ultra-bright LED fixture that offers a uniform light output of 750lm with a glare-free “brightness” (Figure 6). It is part of the WLB32 family, which includes luminaires from 285 to 1130 mm in length with lighting powers from 750 to 3000 lm. These luminaires are designed for workstations, machine lighting, control cabinets and manufacturing lines.

WLB32 light bars are available to form a continuous length of “daisy chain” lighting with a minimum of wiring, while maintaining independent operation of each light bar. Other features are:

- High/Low/Off switch

- Shatterproof window and metal casing

- Flexible installation with magnetic or angle brackets or snap clips

- Screen blocks side glare on some models

- Motion detection on some models

Summary

There is a wide range of performance, cost and environmental factors to consider when specifying industrial lighting solutions. In an increasing number of cases, LED luminaires are an attractive option. Compared to traditional lighting technologies, LED luminaires offer greater lighting flexibility and reliability, and LEDs offer greater energy efficiency, longer lifespan, and reduced maintenance. So while the initial installation costs of LEDs can be higher than other lighting technologies, LEDs offer lower lifetime costs as well as superior lighting solutions.

Source of information: https://www.digikey.com/es/articles/specifying-led-lighting-solutions-for-industrial-environments