Xinyu Liang, Application Engineering Manager

This article presents practical methods to achieve ultra-fast power supply transient response in wireless and especially RF applications. Its purpose is to solve the system designer's challenge of low signal processing efficiency caused by the transient blanking period of the power supply. Example solutions are presented for different applications. The Silent Switcher monolithic power family® 3 for best transient performance is introduced.

Introduction

Signal processing units and system-on-a-chip (SoC) units typically have abruptly changing transient load profiles. This transient charge will cause a disturbance in the supply voltage which is critical in radio frequency (RF) applications, as the clock frequency will be greatly affected by the variable supply voltage. As a result, RFSoCs generally apply clearing time during the load transient. In 5G applications, the data quality is highly related to this blanking period during the transition. Therefore, there is a growing need to minimize the transient load effect on the power supply side to improve system-level performance for any RFSoC system. This article will present several methods used in RF applications to achieve fast transient response in a power supply design.

Fast Transient Silent Switcher 3 Family for RF Applications

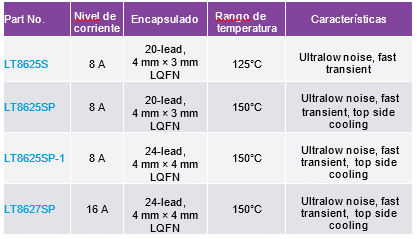

One of the easiest methods to achieve fast transient power rails is to select regulators that feature fast transient performance. The Silent Switcher 3 family of ICs features exceptionally low frequency output noise, fast transient response, low EMI emissions, and high efficiency. It features an ultra-high performance error amplifier design that can provide additional stabilization even with aggressive compensation. The maximum switching frequency of 4 MHz allows the IC to push the control loop bandwidth to the mid-hundred kHz range in a fixed frequency maximum current control mode. The Switcher 3 silent ICs that designers can select to achieve fast transient performance are listed in Table 1.

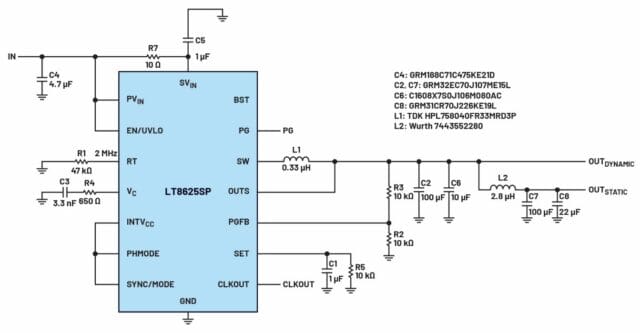

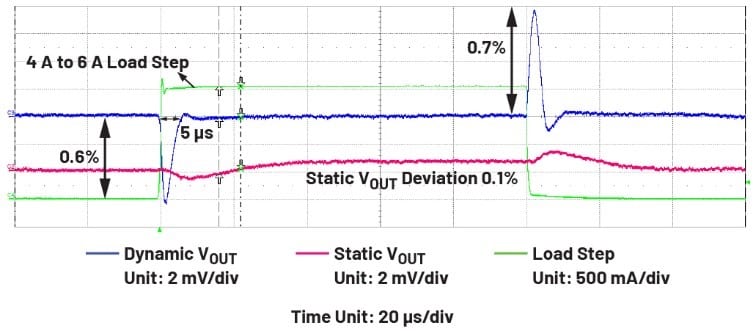

Figure 1 shows a typical 1V output power supply based on the LT8625SP for 5G RFSoC, which needs fast transient response and low ripple/noise at the same time. The 1 V load consists of both related transmit/receive circuits such as local oscillators (LOs) and voltage controlled oscillators (VCOs). Transmit/received loads see a sudden load current change in frequency division duplex (FDD) operation. At the same time, LOs/VCOs see a constant load, but require high critical accuracy and low noise. The high-bandwidth feature of the LT8625SP allows designers to power the two critical 1V load groups from a single IC by separating the dynamic load and static load with a second inductor (L2). Figure 2 shows the output voltage response with a dynamic load transient from 4 A to 6 A. Dynamic load recovers within 5 μs with less than 0,8% peak-to-peak voltage, which minimizes the effect on the static charge side with a peak-to-peak voltage less than 0,1%. This circuit can be modified to accommodate other output combinations, such as 0.8 V and 1.8 V, which can directly supply the RFSoC load without the LDO regulator stage due to ultra-low noise in the low-frequency range, low voltage ripple, and response. ultra fast transient.

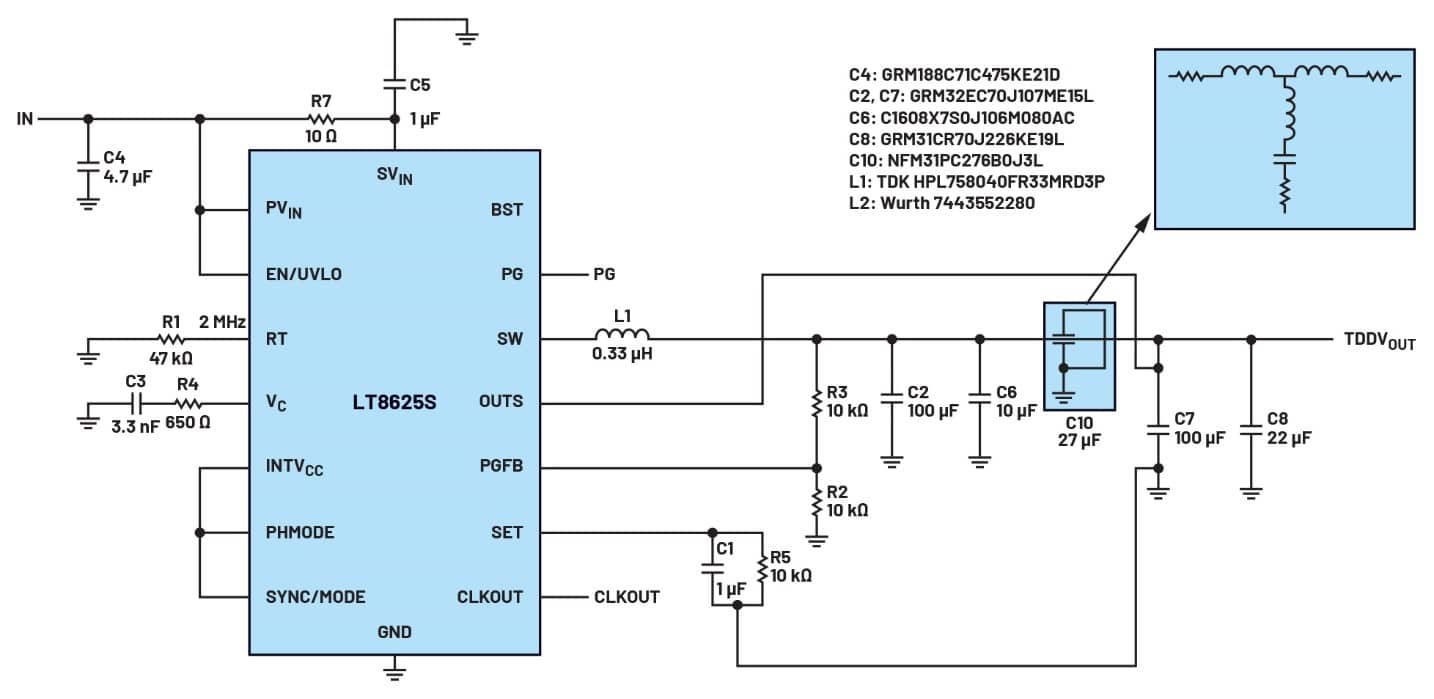

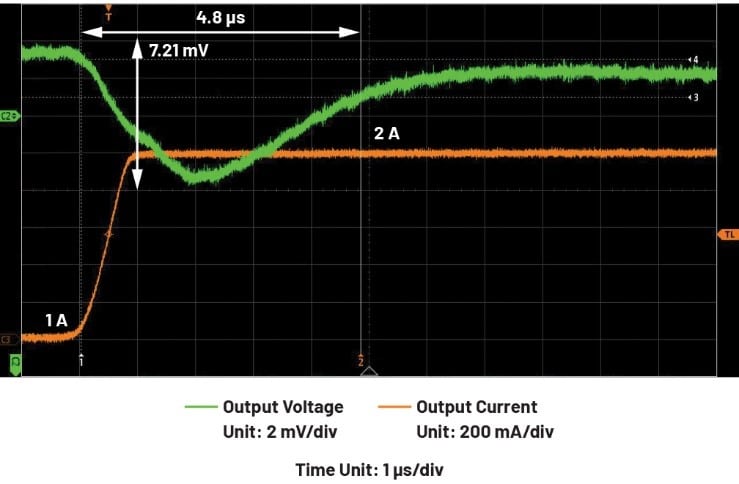

In time division duplex (TDD) mode, noise-critical LOs/VCOs are uploaded and downloaded along with transmit/receive mode changes. Therefore, a simplified circuit as shown in Figure 3 can be used, since all loads are considered dynamic load, while more critical post-filtering is required to maintain the low ripple/low noise function for the LOs/ VCO. A 3-terminal power-mode capacitor can be used to achieve sufficient post-filtering with a minimized equivalent L that maintains fast bandwidth for load transients. The power capacitor together with the remote side output capacitors form two more stages of the LC filter, while all the L's come from the ESL of the 3-terminal capacitor, which is very small and less damaging to load transient. Figure 3 also illustrates an easy remote sensing connection for the Silent Switcher 3 family. Due to the unique reference and feedback generation technology, only the ground of the SET capacitor (C1) and the OUTS pin need to be connected to the point desired remote feedback. No level shift circuitry is needed for this connection. Figure 4 shows a 1 A load transient response waveform with a recovery time of <5 μs and an output voltage ripple of < 1 mV.

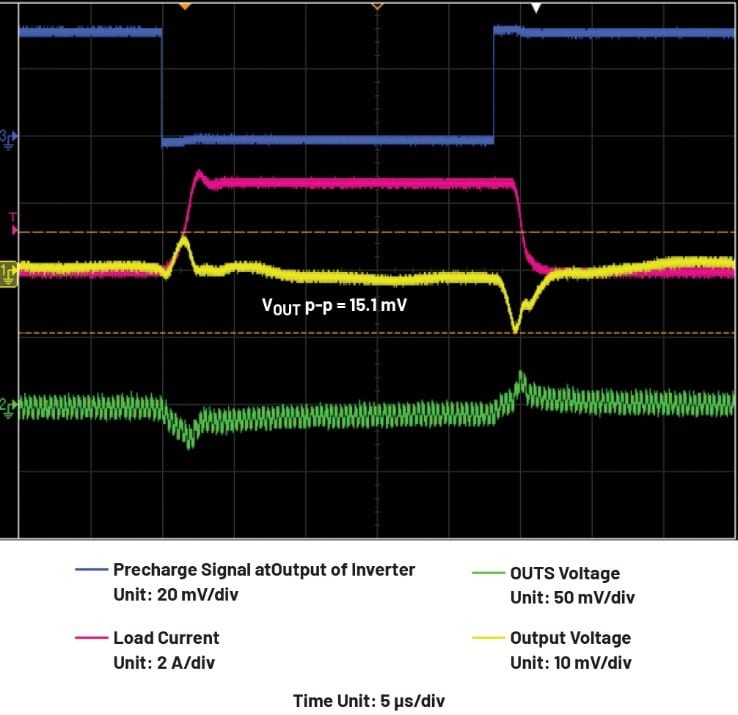

Silent Switcher 3 Family for Actuating Precharge Signals for Fast Transient Response

In some cases, the signal processing unit is powerful with enough GPIOs, and the signal processing is well timed, since the transient event can be known in advance. This is common in some FPGA power supply designs where the precharge signal can be generated to help power the transient response of the supply. Figure 5 shows a typical application circuit that uses the precharge signal generated by the FPGA to provide a bias before the actual load transition occurs so that the LT8625SP can have additional time to accommodate the load disturbance without a bias. of VOUT too big and a recovery time. The FPGA GPIO tuning circuit at the input of the inverter has been omitted since the precharge signal is acting as a disturbance on the feedback. The level is controlled to be 35 mV. Also, to avoid the effect of the precharge signal in the steady state, a high pass filter is implemented between the precharge signal and the OUTS. Figure 6 shows a load transient response waveform from 1.7 A to 4.2 A. The precharge signal is applied to the feedback (OUTS) before the actual load transient, while achieving a recovery time of less than 5μs.

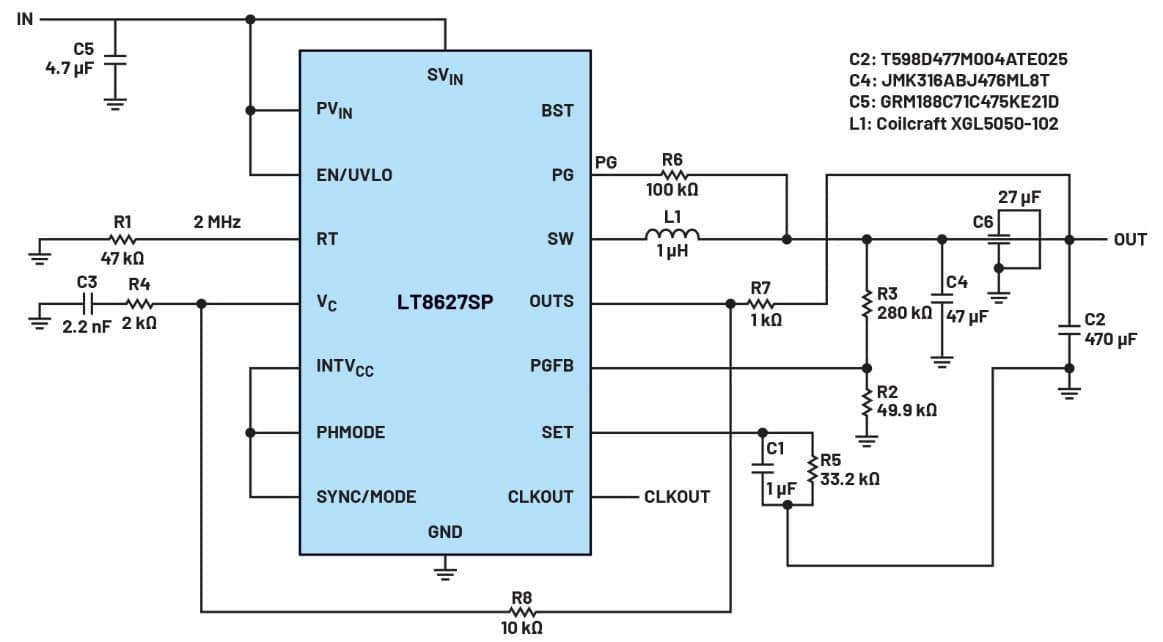

Active Drooping on Circuit for Transient Ultra-Fast Recovery

In beamforming applications, the supply voltage changes all the time to accommodate different power levels. As a result, the accuracy requirement for the supply voltage is typically 5% to 10%. In this application, stability is more important than voltage accuracy, as minimized recovery time during load transient will maximize data processing efficiency. A drooping circuit is a perfect fit for this application, as the dropped voltage will reduce or even eliminate the recovery time. Figure 7 shows the schematic of an active drop circuit for the LT8627SP. An additional drop resistor has been added between the negative input (OUTS) of the error amplifier and the output (VC) to maintain a steady state error in the feedback control loop during the transient. The dropped voltage can be expressed as:

While ∆VOUT is the initial voltage variation caused by the load transient, ∆IOUT is the transient load current, and g is the VC pin for changing the current gain. When designing the drooping circuit shown in Figure 7, special considerations must be taken into account:

- The drooping current must not exceed the current limit of the VC pin. For the output of the LT8627SP error amplifier, it is appropriate to limit the current to less than 200 μA to avoid saturation and this can be achieved by changing the values R7 and R8.

- The drooping voltage must accommodate the output capacitance so that the voltage drift during the transient is at a similar level to the dropped voltage to achieve minimal recovery time during the transient.

Figure 8 shows typical waveforms for the aforementioned circuit during a 1 A to 16 A to 1 A load transient. It is worth noting that now the 16 A to 1 A load transient is no longer limited. by the bandwidth but by the minimum time of the regulator.

Conclusion

The wireless RF field is becoming increasingly computationally dependent and sensitive to transient response time due to the time-critical nature of high-speed signal processing. System design engineers face challenges in increasing the transient response speed of the power supply so that blanking time can be minimized. The Silent Switcher 3 family is the next generation of monolithic regulators optimized for noise sensitive, intensive dynamic load transient solutions in the wireless, industrial, defense and healthcare fields. Depending on the load conditions, special circuitry and techniques can be applied to further improve the transient response.