Demand for internet bandwidth continues to rise, while terrestrial bandwidth has been slow to respond. This is partly because, from an economic point of view, it is not viable to serve about half of the world's population. However, it is an important initiative since making broadband accessible in a general way for the worst-served social segments reduces poverty, improves living standards and is one of the keys to economic growth.

Bandwidth will have to be multiplied by at least 20 to cover internet demand worldwide. More than 100.000 new satellites will need to be deployed in the next ten years in order to achieve this goal, and high-density power solutions will be part of the design of LEO and MEO satellites.

Where terrestrial broadband does not reach, satellite communications are prepared to solve this problem. Satellite communications vendors and OEMs are trying to develop products that take advantage of these excellent growth opportunities. The efforts of companies such as Boeing, which supplies satellites to the European service provider SES for its O3b (other 3 billion) constellation, and to SpaceX, which with its rapidly growing Starlink constellation are at the forefront of providing equal opportunities to billions of people.

To realize this market and social opportunity, satellite communications vendors and OEMs plan to deploy enough capacity to at least 20-fold total bandwidth over the next five years.[b] Boeing, OneWeb , Viasat, SpaceX and others plan to add more than 100.000 satellites in the next ten years[c] and they are all trying to play a big part in the new space race.

To achieve this, the industry is undergoing a huge paradigm shift in satellite system design in order to achieve significant success, as well as a great opportunity to introduce innovative solutions and new companies to take advantage of this boom.

A fundamental element to solve the problem as a whole is to solve the problem of food. New solutions for satellite communications in space require high performance processing which, in turn, consumes more. Space and weight limitations therefore give more importance to advanced, high-density and high-efficiency power solutions that allow these advanced communication systems to be obtained.

Keys to competition for new satellite OEMs and service providers

To compete with terrestrial solutions and capture the expected share of Internet bandwidth growth over the next five to XNUMX years, spatial solutions must be competitive in capacity, coverage, latency, and cost. In order to be competitive, the key strategy in which the companies of the so-called New Space have converged is the deployment of a large number of smaller and connected satellites in LEO (low-earth-orbit) and MEO (medium-earth-orbit) constellations. .

Deploying hundreds or thousands of satellites into lower orbits presents some significant difficulties for system architects and developers. The cost of a satellite, including the cost of launch, has to be reduced by at least an order of magnitude compared to geostationary (GEO) and deep space satellites for this solution to be economically viable.[c] To achieve this cost reduction they need to increase satellite throughput and decrease both size and weight. At the same time, the number of satellites that can be deployed is finite and restricted based on the allocation established by international organizations, so there is an even greater incentive to reach the maximum performance of each satellite. These diametrically opposed requirements, which involve reducing the size and cost of satellites while increasing their performance, along with less exposure to radiation in lower orbits, establish several design criteria that differ from classical applications. space.

Design criteria and requirements for the New Space

One way for developers to address this design problem has been to use increasingly sophisticated on-board processing capabilities. The use of state-of-the-art FPGAs and ASICs with integration levels well below one micron and demanding low-voltage, high-current power requirements has become commonplace to obtain maximum performance in the smallest possible space.[d] The need of more advanced solutions also determines the duration of the mission since, as technology improves, companies will have to change satellites more quickly to take advantage of the latest innovations.

The typical length of a LEO mission and the optimal timeframe for technology upgrade is three to seven years. This proposal can be expensive, and since approval will only be obtained for a certain number of satellites, companies will have to replace them rather than add more. The shorter mission duration also requires rethinking the time to market from the seven to XNUMX years that typically take development and production cycles in half or less. The good news is that lower orbits within the Van Allen belt, coupled with shorter mission durations, significantly decrease the radiation protection needed. This in turn allows more sophisticated and less expensive commercial products to be used with the lower levels of radiation tolerance required for the mission.

Time-to-market requirements drive other changes. Developers try to build off-the-shelf, modular components to increase reliability, decrease test and approval time, and enable much faster and more predictable design cycles. These requirements, coupled with the sheer volume of satellites that OEMs need to produce, place a heavy burden on manufacturing capacity. Modular components are typically assembled in modern manufacturing environments and are robust and commercially scalable, in contrast to older space-grade components, which are typically produced in small numbers and for missions that require fewer satellites. with a higher degree of resistance to radiation.

Improved power grids for the New Space

Similar to other elements in satellite systems, most existing space-grade DC/DC solutions, both isolated and non-isolated, were developed for deeper space missions and have a high degree of reliability and tolerance to radiation. As such, they do not meet the density and efficiency needs of New Space applications. These solutions with maximum resistance against radiation require the manufacture of hermetic encapsulations and the production of small quantities with extremely long cycles due to the high percentage of manual work and numerous tests. A different type of power network is needed to meet the performance requirements of New Space applications, all while providing adequate radiation tolerance.

To achieve these size, weight, and cost improvements through advanced communications processors, as well as shortening time-to-market, an advanced power network capable of delivering high currents at low voltages through dense and efficient power components is imperative. modular type. Compact, modular power components will significantly reduce the size and weight of the power network in three ways:

- They have a higher power density.

2. They reduce the size of the power supply network and increase efficiency, thus reducing the surface area occupied on the printed circuit board with its high copper content.

3. They need less additional filtering.

In general, improving the efficiency and density of the feed network frees up size and weight that can be devoted to payload and satellite subsystems.

Faster time to market, maximum benefits, less risk and cost

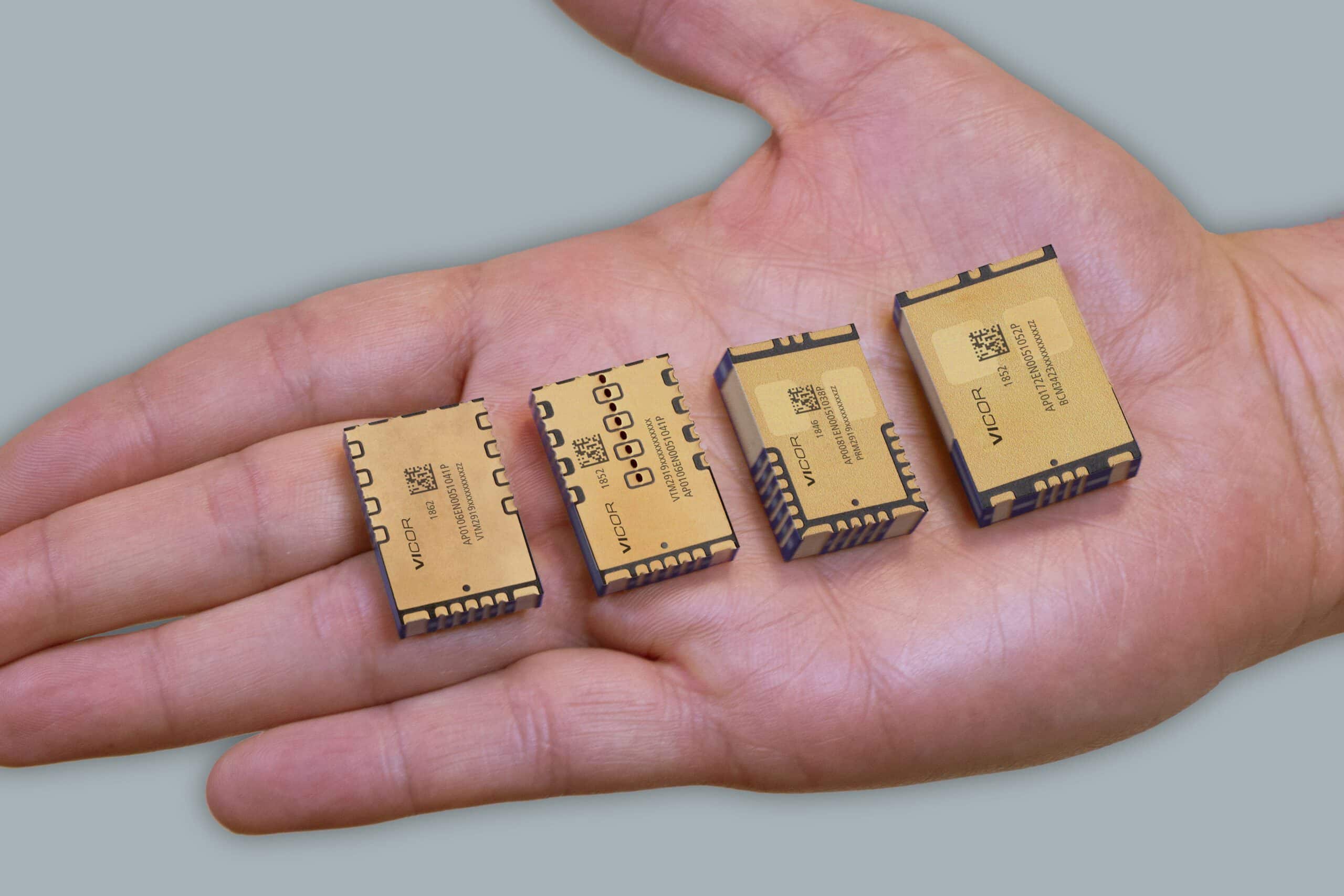

Vicor's radiation-tolerant power modules provide the ideal power network for existing LEO and MEO satellites by providing high-efficiency, high-density, and low-noise voltage conversion to power ASICs and processors for the advanced network communication. Reliability is increased with the dual power stage topology, which together with extensive type approval testing allows our modules to meet TID and SEE radiation requirements on mission.

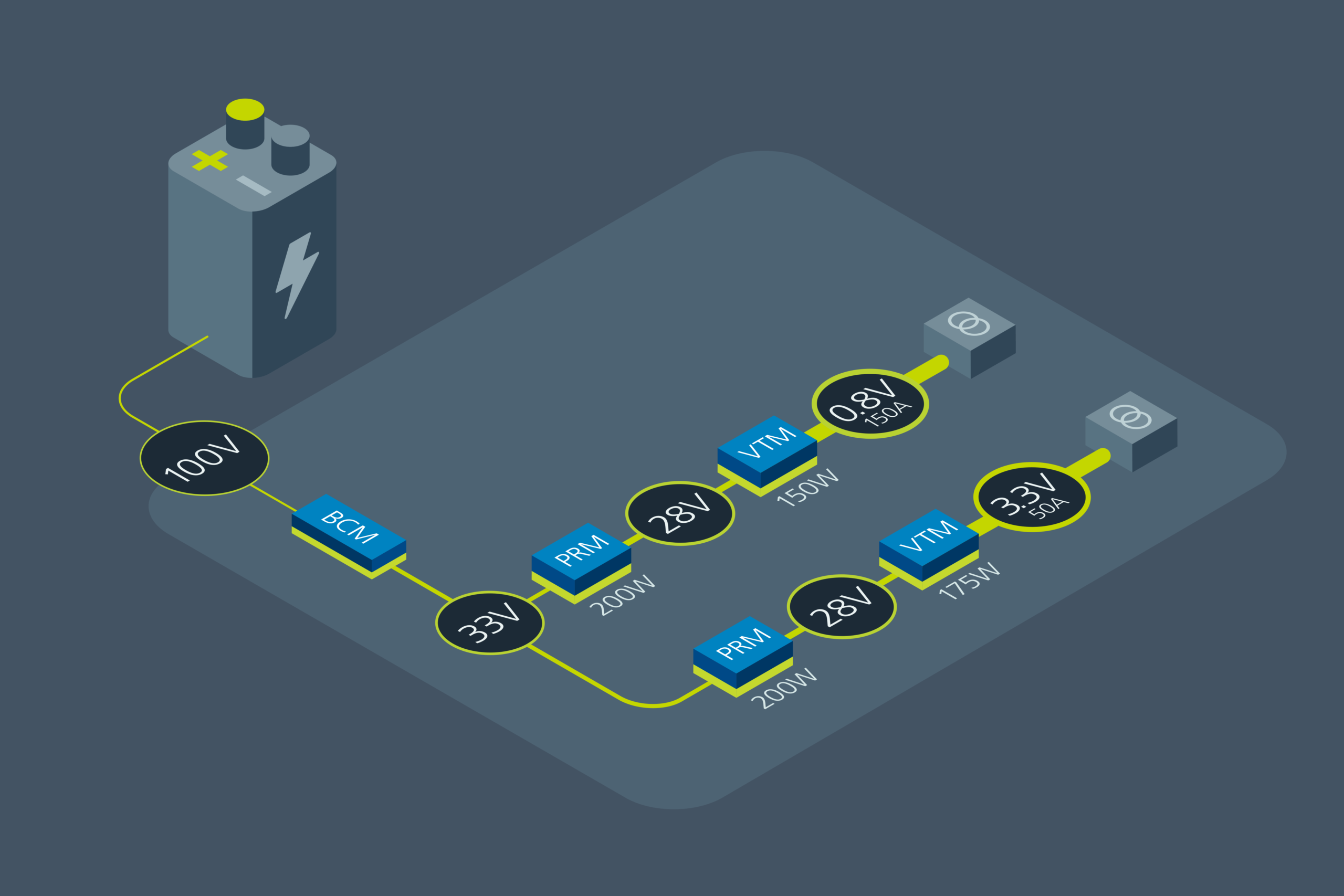

Vicor's modular solutions convert power between source and load, allowing developers to reduce time to market, risk and cost, all while maximizing board space. This Vicor product is capable of powering a 0,8V/150A and 3,3V/50A processor load from a standard 100V bus with efficiencies up to 81%. The next generation modules, which are under development, will improve overall efficiency levels and offer alternative bus solutions.

Among the differential advantages offered by Vicor's new radiation tolerant power modules is an improvement in power density by a factor of 3 to 5 compared to the best solutions currently available, as well as a 50% reduction in power losses for applications based on a 100V bus. Implementing a radiation tolerant solution from Vicor will substantially decrease the board space and weight required by the power network with best-in-class levels of density, efficiency, and acoustic signature.

With long experience as a market leader in both commercial aerospace and high performance processor power solutions, Vicor uses advanced packages and standard SM-ChiP™ mounting techniques in large quantities. All components are manufactured in a US facility with robust manufacturing capability and scalable to large quantities, making it ideal for today's LEO and MEO challenges.

Rob Russell, Vice President of Satellite Solutions, Vicor