By Kurt Dekoski, Molex Business Development Engineer

In response to rising customer expectations, the last decade has seen a major shift in vehicle design priorities. The emphasis of automotive engineers is much more focused on improving the driving experience and making the time spent behind the wheel as enjoyable as possible. An objective that requires –among other initiatives– to reduce background noise in the cabins to an absolute minimum.

There are several sources capable of generating significant levels of noise, from the internal mechanics of the vehicle to the external environment, and all of them can be a nuisance to the occupants. Among the most notable sources of noise are adverse weather conditions (such as wind and rain), tire contact with irregularities in the road, chassis vibrations, the swaying of the vehicle's suspension, the climate control, etc. . However, cabin noise management is not just a matter of comfort. Safety issues should not be overlooked either: studies show that the continuous presence of low-frequency sounds can contribute to driver fatigue and potential safety issues.

Immersed as we are in the midst of the electric vehicle (EV) boom, the need to combat annoying rolling noise in ultra-silent EVs is something that was never considered a priority in traditional vehicles, since electric motors Internal Combustion Engines (ICMs) largely masked road noise. EV models are inherently quieter than their MCI counterparts, as their electric motors don't produce enough noise to drown out the elements.

One solution is to insulate the interior of vehicles with sound-absorbing materials, which would not only consume valuable space in an extremely space-constrained application environment, but would be costly to install and a cost overrun that many automakers would see unnecessary. In addition, this type of passive noise reduction materials can add between 30 and 45 kg to the weight of the vehicle, something without a doubt problematic. Hence, car manufacturers are eagerly looking for an alternative solution based on active noise cancellation technologies.

Active noise cancellation comes to the automotive industry

Putting the principles on which active noise cancellation is based into practice is relatively simple. Using sensor devices, unwanted sound is detected. Processing resources are then used to examine the waveform, and an equivalent, inverse signal is generated to counteract it. This type of mechanism has been used for a long time in audiovisual applications, such as high-end headphones.

However, when implementing this solution in vehicles, certain differences must be considered. The industry requires a compact, lightweight and cost-effective solution, one capable of delivering high performance. As with any component or subsystem intended for an automotive environment, the ability to operate reliably under harsh conditions is vital. The sensor technology used must be robust enough to withstand extreme temperatures, vibrations, impacts, liquid penetration...

Due to its complexity, the configuration of the wiring that connects the set of sensors distributed throughout the vehicle's chassis to the corresponding processing units must seek maximum efficiency, avoiding excessive cost overruns for the bill of materials (BOM). In addition, wire harnesses are responsible for a large part of a vehicle's total weight. Maintaining a low weight is especially important in the design of electric vehicles if you do not want to cut the range between one charge and the next. The lower the weight of the vehicle, the more autonomy!

How to Maximize the Performance of Noise Cancellation Implementations

There are two key performance parameters to consider when measuring the effectiveness of noise cancellation systems. The first is responsiveness. The system must receive and analyze the captured signal in the minimum possible interval and then generate the inverse signal that compensates it, thus achieving acceptable results. That is why, the lower the latency, the more effective the noise cancellation process is. Second, it is vital that the sensors be able to detect as much of the noise signals as possible. Below a certain threshold, the sensors do not pick up the signals and the signals escape the noise cancellation system, and therefore automotive engineers need to specify sensors that have a very low “noise floor”.

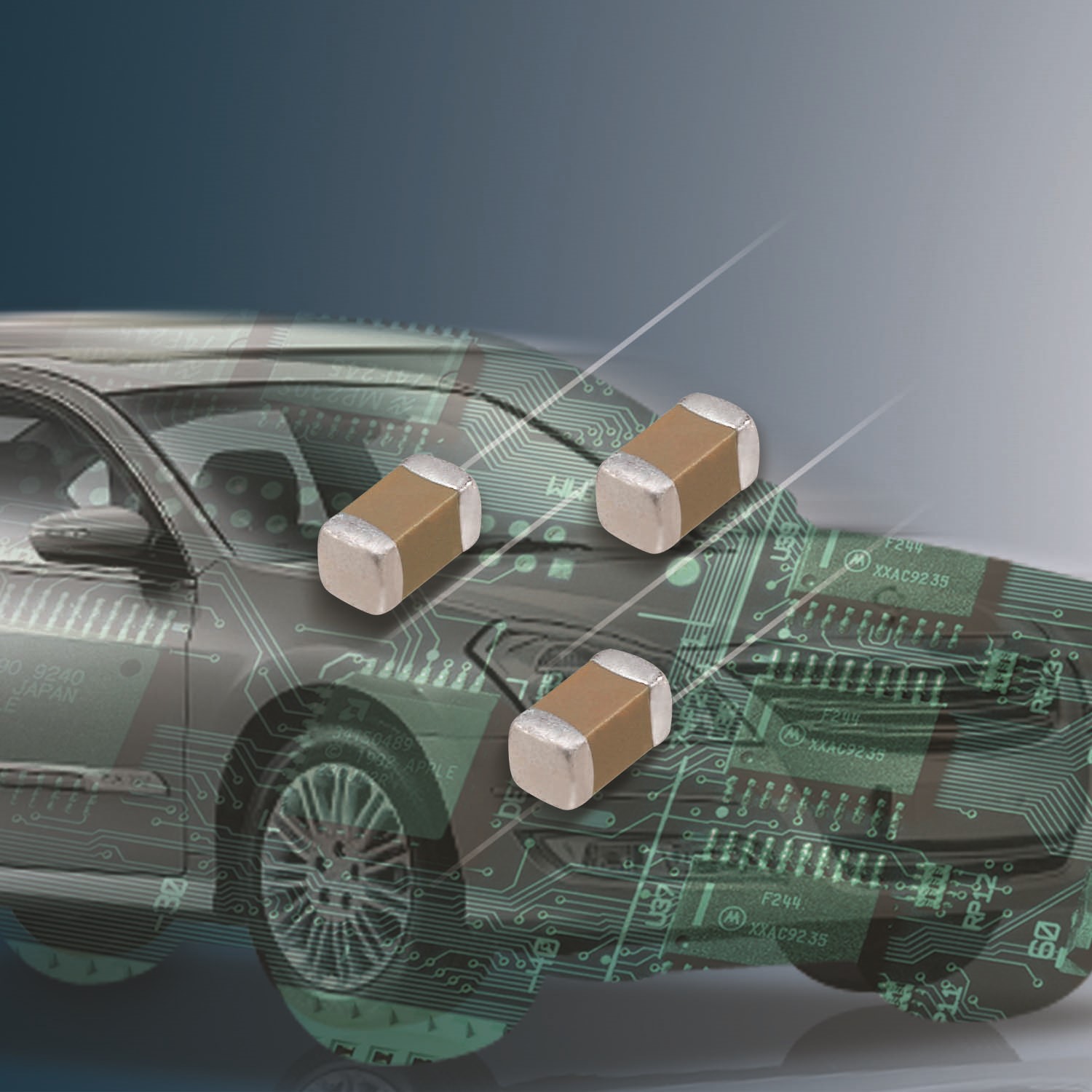

A fully optimized solution for the automotive industry

Through collaboration with semiconductor manufacturer Analog Devices and sound control software developers Silentium, Molex has released a solution that addresses vehicle noise problems. It is not only efficient, but also satisfies specific requirements set by car manufacturers (in terms of wiring weight, BOM costs, continued operational reliability, etc.). Molex Road Noise Cancellation (RNC) sensors incorporate advanced MEMS-based accelerometer technology. In addition, they have latency times of less than 150 μs (typical), a prominent attribute not present in competitive solutions.

The RNC sensors use Analog Devices proprietary interface technology, Automotive Audio Bus (A2B), which enables high-fidelity audio while minimizing cabling so that cost and weight are not prohibitive.

In a conventional system, each sensor would be connected directly to the signal processing unit via individual cables, which is inefficient from both weight and space efficiency perspectives. For its part, interface technology A2B allows a greater number of signals to be processed in each chain and rationalizes the necessary wiring. With the data transfer rates supported by network A2B, RNC sensors take less than 2 ms to transmit noise signals to their assigned processing unit.

Audio A bus technology2B connects all sensors in a daisy-chain arrangement, thereby streamlining the network topology and reducing weight, space, and material costs. Up to nine sensors can be connected along a 30m cable, resulting in a 30% reduction in cabling weight.

To ensure removal of as much noise as possible, Molex RNC sensors offer increased sensitivity. The result: an ultra-low noise floor that allows more of the original waveform to be detected and reacted to. Figure 2 illustrates a sensor device with a noise floor well above 100 µg/√Hz, compared to a Molex RNC sensor (with a noise floor below 100 µg/√Hz) assimilating the captured noise signal. The result is that Molex's RNC sensor is capable of removing 90% of unwanted noise, which is achieved over a wide frequency range from 20Hz to 1kHz. It is even possible to mitigate the noise by driving at lower speeds.

Based on Molex's popular Mini50 family, the connectors used in this active noise cancellation solution save 50% space compared to standard USCAR 0,64mm connectors. The sensors are housed in heavy-duty housings (also available with an IP6K9K rating if required), allowing them to be placed closer to the source of the noise (for example, the road itself) thus speeding up the entire noise cancellation process.

Conclusion

The reduction in the weight of cars and their increasing electrification makes the reduction of rolling noise emerge as a key determining factor. Fortunately, Molex's RNC sensors offer advantages to today's auto manufacturers in designing and implementing a lighter, more powerful, more flexible and more efficient solution when it comes to reducing unwanted noise. For nearly 30 years, Molex has played a key role in the automotive industry with innovative electronic products that help automakers overcome challenges time and time again. Driver fatigue caused by low-frequency noise from electric cars is a challenge that directly affects traffic safety and makes our new RNC sensor technology one of the most relevant solutions of all those presented by Molex. till the date.